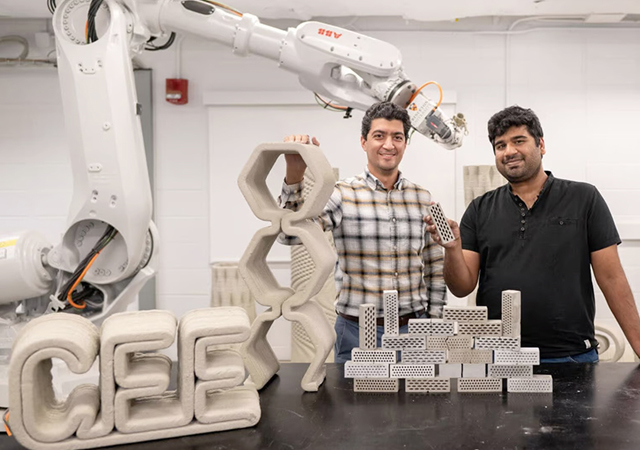

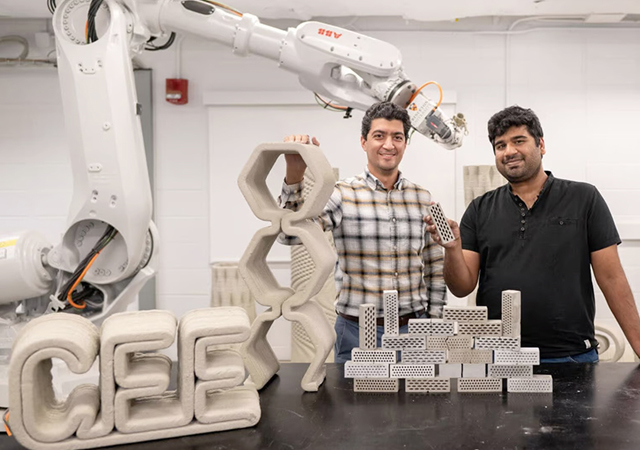

Moini and Gupta with the tougher concrete products they have developed.

Moini and Gupta with the tougher concrete products they have developed.

Researchers at Princeton University in New Jersey, US, are making significant strides in developing tougher concrete through two distinct, but complementary, approaches – a bio-inspired tubular design and double-helical design with robotics.

These two research projects offer promising avenues for developing next-generation construction materials with superior resistance to cracking and damage.

Bio-inspired design

Inspired by the architecture of the human bone’s tough outer layer, engineers at the private Ivy League research university in Princeton have developed a cement-based material that is 5.6 times more damage-resistant than standard counterparts. The bio-inspired design allows the material to resist cracking and avoid sudden failure, unlike conventional, brittle cement-based counterparts.

In a September 10 article in the journal Advanced Materials1, the research team led by Reza Moini, an assistant professor of civil and environmental engineering, and Shashank Gupta, a third-year PhD candidate, demonstrate that cement paste deployed with a tube-like architecture can significantly increase resistance to crack propagation and improve the ability to deform without sudden failure.

“One of the challenges in engineering brittle construction materials is that they fail in an abrupt, catastrophic fashion,” Gupta said.

In brittle construction materials used in building and civil infrastructure, strength ensures ability to sustain loads, while toughness supports resistance to cracking and spread of damage in the structure. The proposed technique tackles those problems by creating a material that is tougher than conventional counterparts while maintaining strength.

Moini said the key to the improvement lies in the purposeful design of the internal architecture, by balancing the stresses at the crack front with the overall mechanical response.

|

|

The double-helical design uses robotic additive manufacturing to weakly connect individual concrete strands. |

“We use theoretical principles of fracture mechanics and statistical mechanics to improve the materials’ fundamental properties ‘by design’,” he said.

The team was inspired by the human cortical bone, the dense outer shell of human femurs that provides strength and resists fracture. Cortical bone consists of elliptical tubular components known as osteons, embedded weakly in an organic matrix. This unique architecture deflects cracks around osteons, preventing abrupt failure and increases overall resistance to crack propagation, Gupta said.

The team’s bio-inspired design incorporates cylindrical and elliptical tubes within the cement paste that interact with propagating cracks.

“One expects the material to become less resistant to cracking when hollow tubes are incorporated,” Moini said. “We learned that by taking advantage of the tube geometry, size, shape, and orientation, we can promote crack-tube interaction to enhance one property without sacrificing another.”

The team discovered that such enhanced crack-tube interaction initiates a stepwise toughening mechanism, where the crack is first trapped by the tube and then delayed from propagation, leading to additional energy dissipation at each interaction and step.

“What makes this stepwise mechanism unique is that each crack extension is controlled, preventing sudden, catastrophic failure,” said Gupta. “Instead of breaking all at once, the material withstands progressive damage, making it much tougher.”

Unlike traditional methods that strengthen cement-based materials by adding fibres or plastics, the Princeton team’s approach relies on geometric design. By manipulating the structure of the material itself, they achieve significant improvements in toughness without the need for additional material.

In addition to improving fracture toughness, the researchers introduced a new method to quantify the degree of disorder, an important quantity for design. Based on statistical mechanics, the team introduced parameters to quantify the degree of disorder in architected materials. This allowed the researchers to create a numerical framework reflecting the degree of disorder of the architecture.

The researchers said the new framework provides a more accurate representation of the material’s arrangements, moving towards a spectrum from ordered to random, beyond the simple binary classifications of periodic and non-periodic. Moini said that the study makes a distinction with approaches that confuse irregularity and perturbation with statistical disorder such as Voronoi tessellation and perturbation methods.

“This approach gives us a powerful tool to describe and design materials with a tailored degree of disorder,” Moini said. “Using advanced fabrication methods such as additive manufacturing can further promote the design of more disordered and mechanically favourable structures and allow for scaling up of these tubular designs for civil infrastructure components with concrete.”

Double-helical design

The research team from Princeton Engineering has also recently developed techniques allowing for a great deal of precision using robotics and additive manufacturing. By applying them to new architectures, and combinations of hard or soft materials within the tubes, they hope to further expand the possibilities of applications in construction materials.

“We’ve only begun to explore the possibilities,” Gupta said. “There are many variables to investigate, such as applying the degree of disorder to the size, shape, and orientation of the tubes in the material. These principles could be applied to other brittle materials to engineer more damage-resistant structures.”

Taking inspiration from nature, the researchers have further improved crack resistance in concrete components by coupling architected designs with additive manufacturing processes and industrial robots that can precisely control materials deposition.

In an article published August 29 in the journal Nature Communications2, researchers led by Moini, describe how their designs increased resistance to cracking by as much as 63 per cent compared to conventional cast concrete.

They were inspired by the double-helical structures that make up the scales of an ancient fish lineage called coelacanths. Moini said that nature often uses clever architecture to mutually increase material properties such as strength and fracture resistance.

To generate these mechanical properties, the researchers proposed a design that arranges concrete into individual strands in three dimensions. The design uses robotic additive manufacturing to weakly connect each strand to its neighbour. The researchers used different design schemes to combine many stacks of strands into larger functional shapes, such as beams. The design schemes rely on slightly changing the orientation of each stack to create a double-helical arrangement (two orthogonal layers twisted across the height) in the beams that is key to improving the material’s resistance to crack propagation.

The paper refers to the underlying resistance in crack propagation as a ‘toughening mechanism’. The technique relies on a combination of mechanisms that can either shield cracks from propagating, interlock the fractured surfaces, or deflect cracks from a straight path once they are formed, Moini said.

Gupta said that creating architected concrete material with the necessary high geometric fidelity at scale in building components such as beams and columns sometimes requires the use of robots. This is because it currently can be very challenging to create purposeful internal arrangements of materials for structural applications without the automation and precision of robotic fabrication.

Additive manufacturing, in which a robot adds material strand-by-strand to create structures, allows designers to explore complex architectures that are not possible with conventional casting methods. In Moini’s lab, researchers use large, industrial robots integrated with advanced real-time processing of materials that are capable of creating full-sized structural components that are also aesthetically pleasing.

As part of the work, the researchers also developed a customised solution to address the tendency of fresh concrete to deform under its weight. When a robot deposits concrete to form a structure, the weight of the upper layers can cause the concrete below to deform, compromising the geometric precision of the resulting architected structure. To address this, the researchers aimed to better control the concrete’s rate of hardening to prevent distortion during fabrication. They used an advanced, two-component extrusion system implemented at the robot’s nozzle in the lab, said Gupta, who led the extrusion efforts of the study.

The specialised robotic system has two inlets: one inlet for concrete and another for a chemical accelerator. These materials are mixed within the nozzle just before extrusion, allowing the accelerator to expedite the concrete curing process while ensuring precise control over the structure and minimising deformation. By precisely calibrating the amount of accelerator, the researchers gained better control over the structure and minimised deformation in the lower levels.

1. The paper, “Tough Cortical Bone-Inspired Tubular Architected Cement-Based Material with Disorder,” was published on September 10, 2024, in Advanced Materials. Funding for the project was provided by the National Science Foundation CAREER Award (2238992) and the CMMI Division Grant (ECI, 2129566).

2. The article, “Tough Double-Bouligand Architected Concrete Enabled by Robotic Additive Manufacturing”, was published August 29 in Nature Communications. Besides Moini, authors include Arjun Prihar, Shashank Gupta, and Hadi Esmaeeli of Princeton. Support for the project was provided in part by the National Science Foundation CMMI Advanced Manufacturing Program (Award # 2217985).

.jpg)

.jpg)

.jpg)