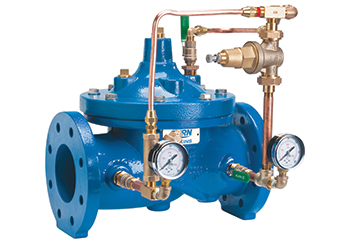

Zurn Wilkins ZW209 ...pilot-operated automatic control valve.

Zurn Wilkins ZW209 ...pilot-operated automatic control valve.

Pressure-reducing valves (PRVs) from Zurn Industries can reduce water consumption by 33 per cent in the average household by merely adjusting the pressure from 100 psi to 50 psi, resulting in reduced resource and sewage treatment and lowering water and sewer bills, according to Universal Building Materials Merchants Company (UBM).

PRVs are used to lower the municipal water supply pressure feeding commercial buildings and homes, according to a spokesman for the Saudi-based UBM, the authorised dealer for Zurn products in Saudi Arabia and a leading player in the kingdom’s building materials segment.

He says pressure-reducing valves are required by code when the street pressure is higher than 80 psi. “In addition to meeting the code, there are numerous benefits to installing a PRV in plumbing or irrigation systems,” he says.

In addition, less water is pumped through the distribution system, resulting in lower energy and heating costs for the water purveyor and sewage treatment facility. PRVs also help extend the life of pipes, faucets, and appliances by reducing wear on system components caused by excessive pressure. Long-term pressure may lead to breakage, causing flooding and property damage, he adds.

The US-based Zurn offers the Wilkins brand of pressure-reducing valves that provide durability and reliability, backed by 100 years of trusted performance, the spokesman adds. “Installing a PRV in the average home will result in annual savings of between 30,000 and 40,000 gallons of water when reducing pressure from 100 psi to 50 psi,” he says.

The PRVs are suitable for irrigation systems, which typically require pressure below 70 psi to adequately water landscapes while reducing water waste. The PRVs maintain this pressure while preventing premature solenoid valve and sprinkler head failure, water hammer, and nozzle fogging. The Zurn Wilkins NR3XL and 500XL PRVs are among the recommended products for such applications.

Also offered by Zurn are pilot-operated automatic control valves, such as the ZW209. The design of these valves is focused on simplifying maintenance and repair; the isolation valves allow for service and maintenance without shutting down the system; union connections simplify pilotry repairs; the wye strainers can be cleaned in-line without system shutdown; and the Hex on the main valve stem allows for use of standard tools.

Other features include pressure gauges for constant system monitoring, epoxy coating that extends the product life, stainless steel hardware that offers corrosion resistance, and simplified maintenance with readily available repair kits – all of which enhance the total cost of ownership.

The ZW209 valve is designed for applications where high inlet pressures need to be reduced to a safe and stable outlet pressure. The pilot assembly reacts to changes in downstream pressure, allowing the main valve to modulate, ensuring a constant downstream set pressure. The pressure regulation is not dependent upon flow rate, resulting in minimal fall-off through the valve.

|

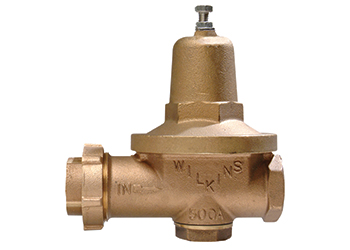

Zurn’s 5000XL pressure reducing valve. |

To avoid and prevent backflow hazards, Zurn offers numerous types of backflow preventers that meet industry standards and provide the right level of protection depending on system conditions.

Backflow is the undesirable reversal of the flow of a possible source of contamination (water or mixture of water and other liquids, gases, or other substances) into the potable water system. It is caused by pressure changes, including conditions of gravity, vacuum, or other pressure changes, the spokesman explains.

He says the majority of contaminated water illnesses and deaths can be prevented if issues or deficiencies within building plumbing systems and groundwater systems are corrected.

“Understanding the backflow prevention terminology is the key to knowing which backflow assembly is appropriate for a given installation. Backflow prevention assemblies are life safety products. If the wrong assembly is specified, the end result can be disastrous,” the spokesman emphasises.

There are two factors that contribute to reversal of flow in pipelines. One is backsiphonage and the other is backpressure.

Elaborating on these two factors, he says: “Backsiphonage conditions exist when there is a negative or subatmospheric pressure in the supply piping, allowing downstream substances to be siphoned into the potable water supply. Under-sized pipes, pipeline breaks, and high withdrawal rates can create vacuums, which contribute to the occurrence of backsiphonage.

“Backpressure conditions exist when a pressure higher than the supply is created in the downstream piping, allowing downstream substances to be pushed into the potable water supply. Backpressure can occur when higher pressures downstream are generated by pumps, thermal expansion, and elevation.”

Zurn offers a range of backflow prevention devices and assemblies including atmospheric vacuum breakers, dual check valves, pressure vacuum breakers, double check valve assemblies, and reduced pressure principle backflow assemblies.

The spokesman says the proper selection of a backflow preventer is crucial to ensure that it works properly and provides adequate protection for the specific application.

Among Zurn’s popular backflow preventers are the 375 and 975XL models.