As part of OQ’s continued digitisation efforts, AssetWise APM is being integrated to develop a digital twin.

As part of OQ’s continued digitisation efforts, AssetWise APM is being integrated to develop a digital twin.

Imagine the scenario: A major Middle East oil plant needs an important replacement part (a compressor). Spares are not available locally and the lead time to secure one through the traditional route would be months. Weighing up this – and the potential loss to production that could result without it – what does its infrastructure maintenance team do? …They charter a 747 to fly to Europe and collect one.

During my 13 years based in the region, helping major energy organisations to more effectively manage and maintain their assets (plants, rigs, wells, pipelines, pumps and so on) and enhance their core work processes with new technologies, I regularly heard this story.

Urban myth or not, it brilliantly encapsulated the challenges that the operations and maintenance teams of major energy infrastructure owner operators across the GCC faced. Components had to be sourced from Europe or America and the lead time, due to a combination of anti-corruption procedures and manual and slow internal processes, could be many months.

The introduction in earnest of the latest enterprise asset management and reliability technologies in the region has helped to make life easier for these organisations – which typically have hundreds of thousands of maintainable and interrelated assets under their stewardship.

|

|

Turner |

The struggles being experienced by Kuwait National Petroleum Company (KNPC) when it called on the services of my team and I (at the firm I worked previously) were typical. It had 31 different systems in place to execute turnaround and maintenance work at three locations.

During a ‘digital integration’ programme, we replaced those with just three, including an industry-leading Enterprise Asset Management (EAM) solution. We also introduced standardised codes and business processes and automated workflows, across the three site locations.

The results: KNPC was able to share inventory (rather than having three separate inventories) and capitalise on economies of scale in making purchases. It was also able to manage global key process indicators from any of the three locations. It calculated the savings from implementing this integrated solution, of $21.46 million per year. The company also experienced a seven per cent reduction in shutdown duration.

Look to the clouds

Fast-forward to today. Many of the region’s major energy organisations have now had in place for some time, EAM systems to help them more effectively operate and maintain their assets. This includes both ‘traditional’ oil and gas groups and those operating in the renewable energy space.

But, at the top-level of industry, no one wants, or can afford, to stand still. Teams at these organisations are now looking to ‘refresh’ their approaches and identify the new technologies and state-of-the-art solutions that will help them with their most pressing problems – including ageing infrastructure, isolated data and unpredictable asset performance.

|

|

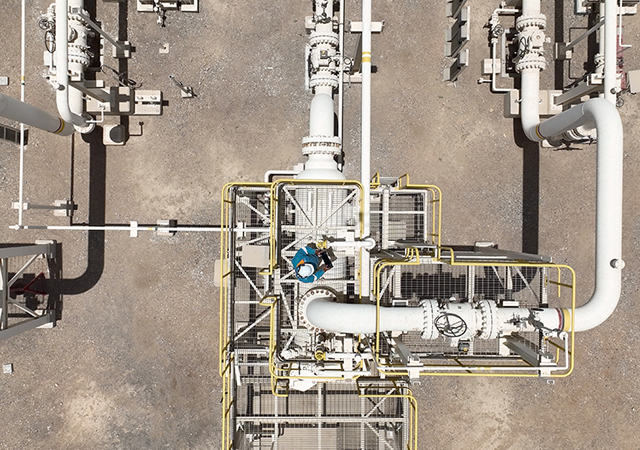

To optimise asset performance and operations, OQ used AssetWise APM to centralise and digitise asset performance, and management processes. |

For asset-intensive organisations in the region, two areas are today key: The cloud and Asset Performance Management (APM). To date, the GCC has lagged behind other regions in its uptake of the cloud. It matters not only because cloud computing removes the need to buy, maintain and upgrade servers but because it positions organisations to exploit generative AI and use it to greatly deepen their understanding of their assets.

APM is another key area that forward-looking energy organisations here should be considering. The successor to Enterprise Asset Management, it is all about looking forward, saying, ‘based on what we know, we predict that this asset is going to fail in xx months’ – and then planning and preparing for that future.

To give you an example of the benefits that can be achieved by introducing APM solutions, OQ (formerly known as the Oman Oil Company) needed a solution which would help it gain total control of its vast portfolio – 111,000 maintainable assets, 44 plants and stations and 4,300 km of pipeline.

Using AssetWise APM as a centralised digital solution has given it that control. It can aggregate asset data from multiple sources, including mobile uploads from field inspections and OQ’s internal computerised maintenance management system (CMMS) to support collaborative, coordinated working by its teams and quick, confident decision making.

|

|

Having a centralised digital asset performance management platform reduced functional failures by 50 per cent and improved asset reliability by 25.7 per cent. |

It has seen asset reliability increase by 25.7 per cent, plant uptime operations maintained at 98 per cent, and flaring reduced by 82.6 per cent, resulting in safer, more efficient, and, ultimately, optimal operations.

It is now looking to take the next step forward – the establishment of a complete digital twin platform to give it a previously unthinkable level of deep knowledge about its assets.

Looking and learning

Energy organisations are also keenly looking and learning from those in other sectors. In February, for example, Diriyah Company, the developer behind Saudi Arabia’s 14-sq-km City of Earth urban development project in Riyadh, piqued interest when it announced it had selected an industry-leading EAM solution to monitor and manage its assets.

Asset management no longer needs to involve panicked responses to unexpected events. With the right technologies in place, energy organisations can ensure their operations are reliable, efficient and smooth-running. And the days of chartering planes to source parts can be put far behind us.

* Tony Turner is a qualified civil engineer and expert advisor on asset management technology and strategy at Bentley Systems.

.jpg)

(1).jpg)