The multifunctional construction robot integrates a vertical telescopic unit and a robotic arm designed for shotcreting.

The multifunctional construction robot integrates a vertical telescopic unit and a robotic arm designed for shotcreting.

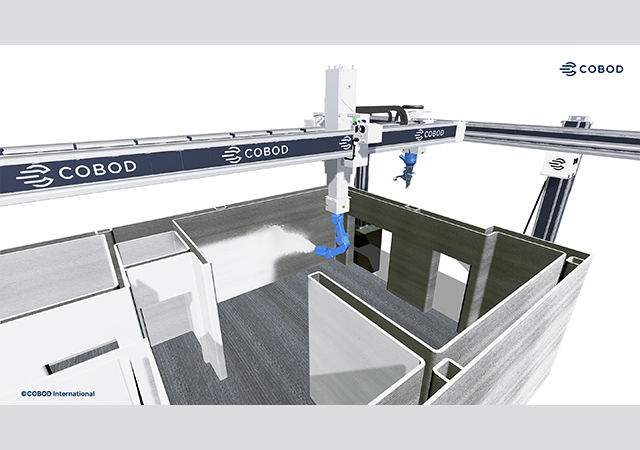

COBOD International, in collaboration with the Technische Universität Braunschweig, has introduced the first commercially available multifunctional construction robot.

Built on COBOD’s 3D construction printing technology, the jointly developed system by COBOD and Institute for Structural Design (ITE) integrates a telescopic vertical extension unit with a robotic arm that enables the Shotcrete 3D Printing Process (SC3DP).

Shotcrete is used to construct complex concrete structures like tunnels, swimming pools and retaining walls, and to reinforce concrete structures.

However, the telescopic tool is not limited to shotcrete applications, multiple other tools can also be mounted onto the vertical telescopic unit. The unit is mounted between two X-axes on a COBOD BOD2 3D construction printer.

|

|

Lund-Nielsen demonstrates the use of the construction robot. |

The technology was demonstrated at the grand opening of the Digital Construction Site at TU Braunschweig last month.

Helga Kühnhenrich, Head of the Research and Innovation at the Construction Department of the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR), attended the launch event, underlining the national support for automating and digitalising construction to meet future construction and housing needs.

At the event, Henrik Lund-Nielsen, General Manager and Founder of COBOD International, said: “For years we have had the vision of making multifunctional construction robots on the basis of our 3D construction printers. Seeing the first materialization of our vision here makes me very proud. With this new technology we offer automation of many more construction processes than just printing of concrete walls.”

|

|

COBOD BOD2 printer can be turned into a multifunctional construction robot, equipping the vertical telescopic unit with a spray gun to paint the walls. |

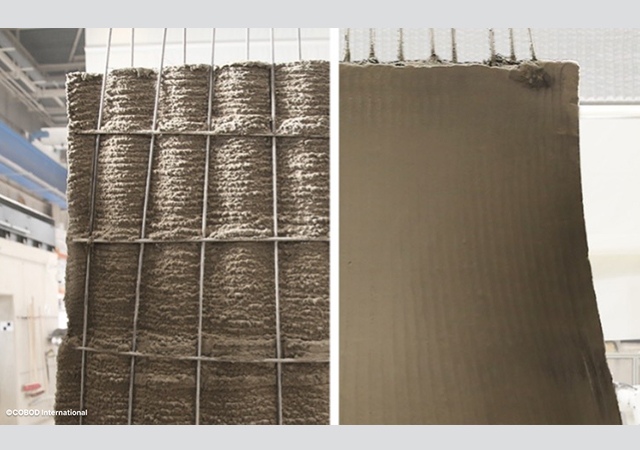

TU Braunschweig intends to use the system delivered to shotcrete 3D-print digitally fabricated reinforced concrete structures with high surface quality and geometric freedom.

The reinforcement is seen as an integral part of the SC3DP process, where either the concrete is built up first and then the reinforcement is inserted, or the reinforcement with a pre-fabricated shape and a mesh, which is shotcreted from both sides. Additionally, the robotic arm can be equipped with sanding equipment to finish the surfaces.

Professor Harald Kloft for Structural Design at ITE said: “Our partnership with COBOD is a decisive step towards the digital construction site of the future. 3D printing enables automated, digitally controlled processes of simple as well as very complex tasks, like the fabrication of reinforced double curved walls.”

|

|

TU Braunschweig intends to use COBOD’s multifunctional construction system to fabricate reinforced double curved walls. |

“The ability to produce complex, individualised, material-efficient and low-waste construction solutions makes 3D printing ideal for the construction industry, as it brings together economic, environmental and social benefits, while reducing physical stress,” he noted.

With a dynamic vertical range of 3 m of the telescopic unit, the robotic arm can fully reach and manipulate an already printed wall 3 m below the X-axis.

COBOD emphasises that a variety of tools can be mounted on the new COBOD robotic arm, such as a paint spray gun, insulation tool, sanding equipment etc, hereby turning the 3D construction printer into a multifunctional construction robot capable of much more than just the printing of the walls.

By installing a gripper system at the end of the robotic arm, the system can even be used to automatically mount aerated concrete blocks or bricks or other types of pre-fabricated building components not usually associated with 3D printing solutions, underlining the new multifunctional capabilities of the printing system.

.jpg)

(1).jpg)

Doka (2).jpg)