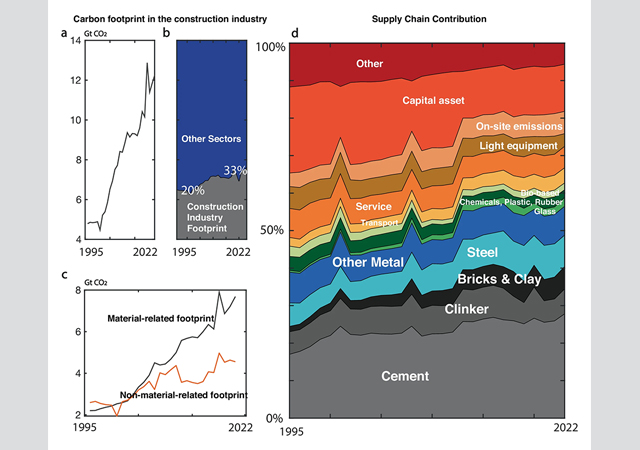

Engineers at Australia’s RMIT University have developed a ground-breaking sustainable building material called cardboard-confined rammed earth, which combines cardboard, soil, and water to create structural components that are claimed to have about one quarter of concrete’s carbon footprint.

This innovative material is fully reusable and recyclable, significantly reducing cardboard waste that is otherwise sent to landfill – over 2.2 million tons annually in Australia alone – and cutting emissions linked to cement and concrete production, which account for around eight per cent of global emissions.

Unlike traditional rammed earth construction that incorporates cement for strength, this new method eliminates cement by using cardboard as formwork that confines the rammed soil mixture, making it strong enough to support low-rise buildings at less than one third the cost of concrete.

The cardboard-confined rammed earth can be compacted manually or mechanically onsite, using mostly local soil, which could drastically reduce transport, logistics, and upfront material demands in remote areas and fit well with circular economy goals and net-zero carbon ambitions.

|

|

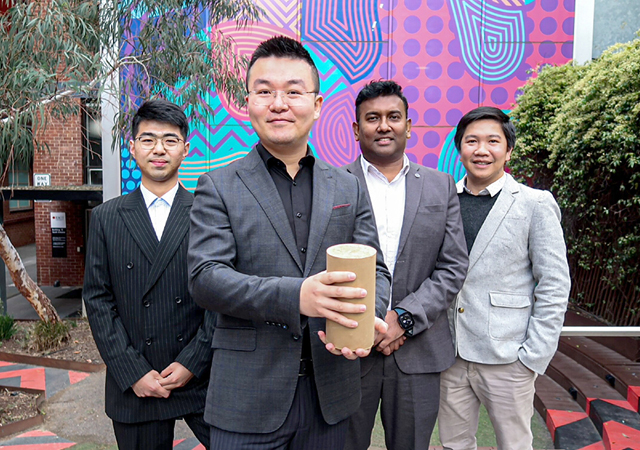

Dr Ma holding the cardboard-confined rammed earth material. |

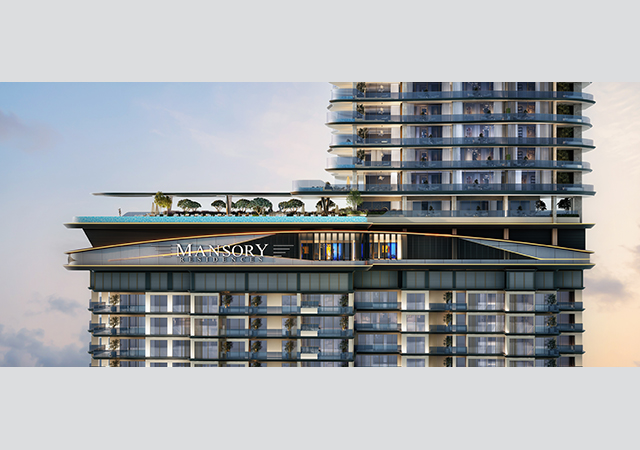

The high thermal mass of rammed earth naturally regulates indoor temperatures and humidity, making this technology especially suitable for hot climates like those found in the Gulf region, where passive cooling is key to reducing energy use. This approach can revolutionise sustainable building by emphasising local materials, recycling, and low carbon footprint.

Cardboard has previously been used in temporary structures and disaster shelters, such as Shigeru Ban’s iconic Cardboard Cathedral in Christchurch, New Zealand. Inspired by such designs, the RMIT University team has, for the first time, combined the durability of rammed earth with the versatility of cardboard.

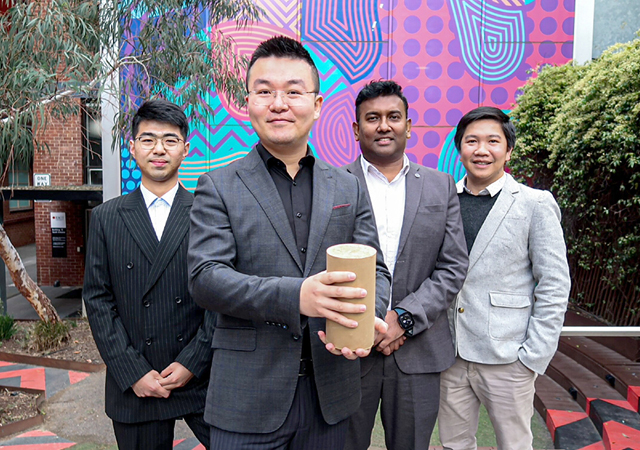

Lead author Dr Jiaming Ma from RMIT said the development of cardboard-confined rammed earth marked a significant advancement toward a more sustainable construction industry.

“Modern rammed earth construction compacts soil with added cement for strength. Cement use is excessive given the natural thickness of rammed earth walls,” he said. “By simply using cardboard, soil and water, we can make walls robust enough to support low-rise buildings.”

“This innovation could revolutionise building design and construction, using locally sourced materials that are easier to recycle. It also reflects the global revival of earth-based construction fuelled by net zero goals and interest in local sustainable materials.”

PRACTICAL BENEFITS

The cardboard-confined rammed earth can be made on the construction site by compacting the soil and water mixture inside the cardboard formwork, either manually or with machines.

|

|

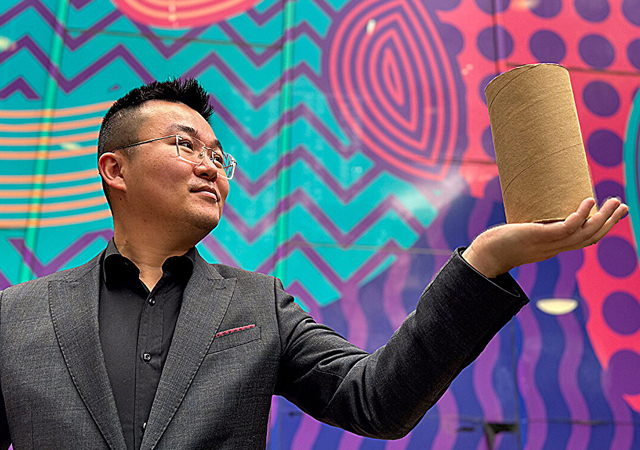

A cardboard-confined rammed earth column and a CFRP-confined rammed earth column. |

Study corresponding author and leading expert in the field of structural optimisation, Emeritus Professor Yi Min ‘Mike’ Xie, said this advancement can spearhead a leaner, greener approach to construction.

“Instead of hauling in tonnes of bricks, steel and concrete, builders would only need to bring lightweight cardboard, as nearly all material can be obtained on site,” Xie said. “This would significantly cut transport costs, simplify logistics and reduce upfront material demands.”

“Rammed earth buildings are ideal in hot climates because their high thermal mass naturally regulates indoor temperatures and humidity, reducing the need for mechanical cooling and cutting carbon emissions,” he said.

The mechanical strength of the novel material varies based on the thickness of the cardboard tubes.

Dr Ma said the team has developed the formula for this strength design.

“We’ve created a way to figure out how the thickness of the cardboard affects the strength of the rammed earth, allowing us to measure strength based on cardboard thickness,” he said.

The RMIT research team, led by Dr Ma, has also explored reinforcing rammed earth with carbon fibre, demonstrating strength comparable to high-performance concrete for more demanding applications. The team is now seeking industry partners to further develop and scale up this low-cost, eco-friendly construction solution for broader adoption.

.jpg)