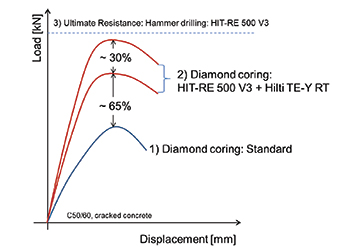

Figure 1: Load displacement curves of different mortar systems installed in diamond cored drilled holes.

Figure 1: Load displacement curves of different mortar systems installed in diamond cored drilled holes.

Hilti, which created a stir in the market in 2014 with its innovative SafeSet system for the hammer drilled boreholes market, has now launched yet another revolutionary product – this time for diamond cored applications.

“With its HIT-RE 500 V3 mortar system and Hilti TE-Y RT roughening tool, Hilti has taken another giant step in bringing reliability back to diamond cored applications,” says Karel Ludvik, head of engineering for Hilti Corporation, a Liechtenstein-based provider of leading-edge technology to the global construction industry.

He points out that a drilling system can have a significant impact on the required cleaning process of the borehole and on bond strength of bonded/adhesive anchors and post-installed rebar.

The key drilling techniques used include:

• Rotary-impact drills (hammer drills) for anchoring applications;

• Percussive/compressed air rock drills for post-installed rebar with large diameters and long development/anchorage length; and

• Diamond core drills for anchoring applications where the existing reinforcement is expandable.

Hilti hammer drills are the preferred approach for most applications given their portability and ease of use, states Ludvik, adding these drills produce a non-uniform borehole surface especially suitable for enhancing the bond (provided correct hole cleaning procedures are used).

Inadequate cleaning of the drilled hole allows for the retention of dust on the sides of the hole and can have a pronounced effect on the load displacement behaviour and ultimate load/bond strength, he says. This is because the drilling dust smoothens the peaks and valleys of the borehole surface, resulting in decreased roughness and decreased mechanical interlock and hence reduced bond strength.

Consequently, Ludvik says, Hilti launched in 2014 the revolutionary adhesive anchor system – Hilti HIT-HY 200 plus the hollow drill bits and Hilti HIT-Z as part of the Hilti SafeSet system.

“Hilti SafeSet Technology eliminates the hole cleaning factor almost entirely and improves reliability and productivity,” he points out.

|

|

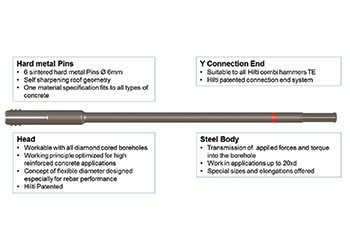

Hilti TE-YRT Flex Fork ...roughening tool. |

Turning to compressed air rock drills, Ludvik says these drills operate with compressed and oiled air to reduce abrasion of the drill poles as much as possible. They offer drilling speed and efficiency and produce a rough hole surface – rougher than that of the rotary hammer drills – for increased bond due to the large impact energy. However, this energy may increase the risk for damage in the concrete member, particularly if used in applications with small edge distance or reduced backside cover. Therefore, rock drills typically require larger edge distances/member thickness.

Meanwhile, diamond core drills bits utilise a sacrificial matrix containing diamond fragments to abrade the concrete. However, since diamond core drilling is usually accomplished using water, drilling slurry is created in the drill hole which must be removed and cannot be allowed to dry because it might affect the anchor tensile capacity. Given the limited time frame between coring and borehole cleaning, for diamond cored qualified systems, specific hole cleaning procedures have been developed to optimise bond. However these procedures are even more tedious than those for hammer drilling.

Also, core drills typically produce a very smooth and geometrically regular cylindrical hole. The roughness parameter of a diamond cored drilled hole is only ~65 per cent (C20/25) and 35 per cent (C50/60) of a hammer drilled hole. Consequently, one can assume a significantly reduced mechanical interlock effect of bonded anchors and post installed rebar in diamond cored drilled holes.

Bond strength was calculated from pullout tests with rebar elements anchored in different concrete strength classes (C20/25 and C50/60) when using hammer and diamond drilling techniques. The bond strength values of rebar installed in diamond cored drilled holes was significantly lower compared those installed in hammer drilled holes in both low and high strength concrete. In addition, a decrease of the bond strength values in high strength concrete compared to low strength concrete can be detected for diamond cored drilled holes. This is significant in that engineers tend to assume low-strength concrete even when using high-strength product to build in “an additional safety margin”.

Hence, following the success of the HIT-HY 200 and Hollow Drill Bits for hammer drilled applications, Hilti has extended the Hilti SafeSet concept to diamond cored drilled holes using the new mortar system Hilti HIT-RE 500 V3 in combination with Hilti TE-Y RT roughening tool.

The new TE-Y RT “Flex Fork” roughening tool roughens the sides of the smooth diamond cored hole allowing increased mechanical interlock between mortar and concrete. This results in much higher bond strength values and reduced and simplified cleaning steps.

Ludvik explains: “After drilling the hole, the roughening is created with the help of the patented flex fork with six sintered hard metal pins with very high abrasion resistance. The rotation of the steel body with a length up to 60 diameter brings the hard metal pins into contact with the concrete while the drilling actions permit the hard metal pins to roughen the surface of the borehole to a degree where mechanical interlock and consequently bond performance with Hilti mortar is guaranteed.”

Figure 1 shows schematic load displacement curves of different mortar systems installed in diamond cored drilled holes in high-strength (C50/60) cracked concrete.

Curve 1 represents a standard mortar system (“Flush – Brush – Blow” cleaning method) while Curve 3 represents the Hilti mortar system HIT-RE 500 V3 where the borehole was roughened prior to cleaning. The horizontal dotted line 3 represents the ultimate resistance by means of the maximum achievable load (hammer drilled borehole under the same base material conditions).

The roughening with Hilti TE-Y RT means up to 65 per cent higher bond performance compared to standard installation in diamond cored drilled holes and nearly 70 to 100 per cent of the ultimate resistance in case of hammer drilled borehole.

This comes with the benefit of significantly reduced installation time – up to 50 per cent less – because roughening needs fewer cleaning steps.