Aluminium Bahrain (Alba), one of the world’s largest aluminium smelters, marked a new milestone in its Power Station 5 (PS5) Block 4 Project with the recent arrival of Mitsubishi Power’s M701JAC Gas Turbine (GT).

The M701JAC GT is a first-of-its-kind gas turbine manufactured in the world for a primary aluminium smelter.

The JAC GT, an air-cooled version of the J-series GT and steam turbine, has a combined cycle output of 680.9 MW and reduces CO2 emissions when compared to conventional coal-fired boilers and turbines worldwide.

Commenting on the occasion, Alba’s CEO Ali Al Baqali said: “We are pleased to see the gas turbine at Alba’s project site as that will bring us one step closer to boost our operational efficiency while accelerating our ESG transformation in line with the Kingdom’s objectives of net zero emissions by 2060.”

“The state-of-the-art JAC GT will enable Alba to reduce its GHG emissions and deliver clean energy. This GT will support our vision, once fully commissioned, to be a sustainable and responsible aluminium producer. I thank our partners Mitsubishi Heavy Industries and SepcoIII for their support to progress with this project’s milestones safely and on time. I also want to thank our project team for achieving to date around 1.5 million safe working hours without LTI,” he stated.

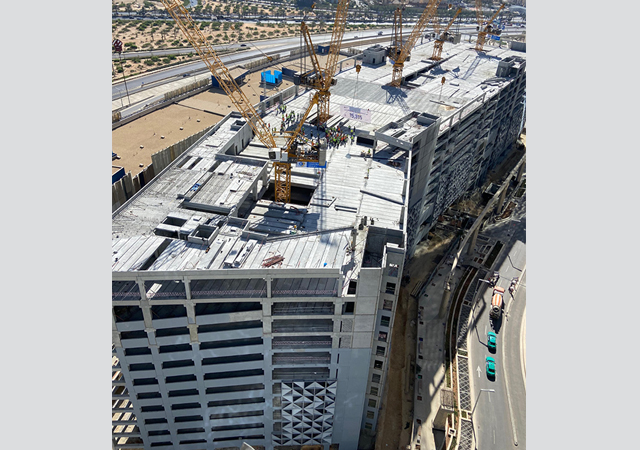

Alba said its PS5 Block 4 Expansion Project is the addition of a fourth block of similar combined cycle configuration with 680.9 MW M701JAC gas turbine combined cycle and includes tie into the existing 220 kV substation.

Once operational in Q4 2024, Block 4 will increase the nameplate capacity of the PS5 Complex from 1,800 MW to 2,481 MW and reduce its overall GHG emissions intensity ratio by 0.5 tonnes of CO2 per 1 tonne of aluminium produced.