Tental facades provide maximum transparency with minimum view of profiles.

Tental facades provide maximum transparency with minimum view of profiles.

Technal, a leading architectural aluminium systems brand with a presence of more than 40 years in the region, has recently launched worldwide a new aluminium system for building envelopes that offers multiple creative options, enables the use of large glazing units and is claimed to have the lowest environmental impact.

The Tental Curtain Wall, as it is called, has four new patents which allow for optimising materials, simplifying manufacture, and facilitating installation – which is carried out dry, with no glue or sealants used on site, no packaging and no waste, says Technal, which is owned by the Norwegian multinational Hydro group, the world’s largest producer of aluminium.

“The Tental Curtain Wall was created with a view to offering architects and consultants an extensive range of solutions, giving them as much creative freedom as possible when designing a façade,” explains Hesham Kameshki, Marketing and Business Development Manager at Bahrain-based Hydro Building Systems Middle East, the regional headquarters for Technal. “It is a unique platform, with 50 mm and 60 mm wide aluminium profiles, that allows for designing modular curtain-walls with large‐sized glazing units, in line with the latest trends towards maximum transparency with minimum view of profiles.”

Each module can integrate panels weighing up to 850 kg, with a surface area of more than 12 sq m, depending on the type of glass used.

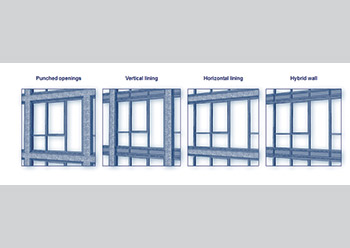

According to Technal, the system offers a wide range of aesthetic solutions to adapt to the requirements of any project: from the capped to the semi‐capped design – which emphasises either the horizontal lines of the transoms or the vertical lines of the mullions – to the flat cap, creating a smooth look of the profiles and glazing. A wide range of caps designs are available for these configurations.

Tental also includes the structural silicone glazing option to create completely flat curtain-wall systems without profiles visible from the outside; and bead glazing, where the glass is attached by means of aluminium beads that form a visible grid. The system can be used for sloped glazed roofs. In addition, all profiles can be customised in different colours and textures – which range from Technal’s exclusive metallic tones to a wide choice of lacquers, anodised satin finishes or wood-effect lacquers. It is also possible to use wooden structural profiles on the inside of the curtain-wall.

“The modules are capable of integrating double or triple glazing up to a maximum thickness of 62 mm, resulting in excellent thermal, acoustic and waterproofing performance (up to 1,500 Pa), which, in turn, means high levels of interior comfort. Users can also access an extensive range of windows, doors and sliding doors compatible with this curtain-wall system. Safety is guaranteed with a burglary resistance that meets the highest standards, in accordance with international regulations,” says Kameshki.

Sustainability

Solar shading systems can be integrated into the curtain-wall, which, along with reduced thermal transmittance, makes the architect’s job easier when it comes to designing energy‐efficient buildings. Also, the embodied energy in the aluminium curtain-wall is significantly lower, due to having profiles made using Hydro Circal 75R, the first certified post‐consumer recycled aluminium (see Gulf Construction, May 2021).

Mullion remnants are used as transom profiles, reducing the required number of profiles up to 25 per cent, says Technal. Furthermore, Tental’s thermal-break elements are made from recycled xPET, a material that gives a second life to everyday water and beverage bottles, thereby preventing them from ending up in landfill or in the sea.

The circular economy not only applies to the materials used to manufacture the curtain-wall, but also its design: all components can be easily assembled and disassembled mechanically, simplifying the separation and recycling thereof once they come to the end of their life cycle, Technal points out.

This ability to reuse materials and the efficient use of water and renewable energy in the production phase means Tental can opt for a Cradle to Cradle label which is under certification, it adds.

The greenhouse gas emissions attributable to the Tental manufacturing process are among the lowest that the building industry can offer for an aluminium curtain-wall, Technal claims, adding that this effectively contributes to constructing sustainable buildings that are eligible to be awarded the most prestigious environmental certifications such as LEED, BREAM, WELL, VERDE, and LEVEL(s).

“Once again, the use of Hydro Circal 75R is decisive, as it only emits 2.3 kg of CO2 per kg of aluminium, compared to a global average of 18 kg of CO2 per kg of aluminium. This data is certified by independent bodies and is available to professionals on request through EPDs (Environment Product Declarations).

“In summary, the Tental curtain-wall is the perfect solution to meet sustainable design and construction requirements and fully backs up Technal’s commitment to the circular economy, allowing creative freedom to architects,” Kameshki concludes.

.jpg)

(1).jpg)