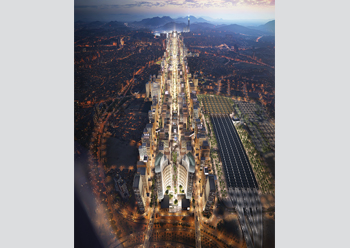

The energy hub is taking shape over a 50-sq-km site in the Eastern Province.

The energy hub is taking shape over a 50-sq-km site in the Eastern Province.

Given the demand it has witnessed from investors in setting up base at King Salman Energy Park (Spark), the region’s only fully integrated energy hub has accelerated the second phase of infrastructural development, according to the President and CEO of the mega global energy hub fast taking shape over a 50-sq-km site in the Eastern Province of Saudi Arabia.

In an exclusive interview with Gulf Construction, Saif Al Qahtani says: “The second phase has been partially accelerated due to demand, by adding more industrial clusters and expediting the logistical zone infrastructure and dry port. The masterplan is being revisited for further acceleration in alignment with market potential.”

Construction will start shortly for the 3-sq-km logistics zone and dry port, Al Qahtani adds.

“Despite some setbacks experienced as a result of the Covid-19 pandemic, Spark has continued to make progress on construction and has realigned with its forecasted targets for the completion of Phase One in December 2021,” he says.

|

|

Al Qahtani ... eyeing first phase completion. |

Al Qahtani indicates that around 80 per cent of the work has been completed on the first of the three phases of infrastructure development including roads, utilities and real estate assets over 14 sq km.

Excerpts of the interview:

What are the unique selling points of the Spark development? What are the incentives offered/attractions for investors to set up operations at Spark?

King Salman Energy Park, the region’s only fully integrated energy hub, is being developed to capture the full economic value of the region’s high demand for energy-related goods and services. Spark will become a 21st century ecosystem for the energy sector, a vibrant industrial community built on excellence and innovation, and will have at its heart, a world-class workforce.

Strategically located at the heart of the global energy market, Spark is focused on providing investors with ease of access, ensuring that supply chain and raw material companies are located in close proximity or are easily accessible through our Logistics Zone which includes a dry port, bonded area and a future railway connected to neighbouring countries.

Enabling our investors to capture market share and demand growth is a key priority for Spark. The energy city offers ready-to-lease land with fully integrated infrastructure and utilities to reduce development timelines and cost for new factories. We make investing in the kingdom’s energy sector easy, providing a single point of contact to address all investors’ needs. We also make investing in the energy sector as efficient as possible by anticipating all our investors’ needs and employing standardised qualification and leasing processes to enable investors to sign provisional lease agreements within three to 10 weeks. Spark also offers non-industrial development to third-party investors to develop residential, commercial and recreational facilities as part of our work-live-play offering.

|

|

Spark is utilising ConXtech technology for the construction of a commercial building. |

Spark is a connected, accessible and fully-integrated ecosystem offering world-class infrastructure and support facilities which will also enable the localisation and integration of energy supply chains. Through our partnership with Oilfields Supply Company Saudi (OSC), a 1-million-sq-m Common User Supply Base will create a favourable environment for small and medium enterprises (SMEs) and startups to gain access to their customers by providing pre-built industrial manufacturing facilities, de-risking the set-up phase for investors. The OSC facility offers the flexibility for investors to rent short-term or on demand, offering a multitude of support services to accelerate business growth.

Are there specific zones dedicated for Spark’s five focal areas?

Spark has created various zones for multiple types of investors. The industrial zone will be a global hub for energy-related manufacturing services with best-in-class infrastructure, utilities and services across the energy value chain. The industrial zone is open to investors from across the energy supply chain including upstream, downstream, petrochemicals, power and water treatment facilities. The non-industrial zone is a 7-sq-km site which includes office and administrative buildings, a digital hub, housing and accommodation, as well as commercial and municipal infrastructure. Our logistics zone will be anchored around the Spark dry port and will comprise warehouses, redistribution facilities and related services, a future GCC rail system and storage areas to enable investors to import and export their products directly from Spark to their customers.

|

|

The Logistics Zone ... work to start shortly. |

What is the strategy employed by Spark to ensure the right mix of tenants to encourage healthy competition and synergy between the various tenants?

Spark is envisioned to attract companies that support the energy industry. The park has been masterplanned around clusters with similar industries to ensure we drive synergies. We are also planning to attract the different tiers of the value chain to create logistics efficiencies while localisation to full value in the kingdom.

How many tenants has Spark attracted to date? What is the total foreign direct investment in the park?

Spark’s value proposition targets investors and partners of all sizes. To date, it has signed agreements with 23 major energy companies to invest in the energy park, with an additional 12 companies in the pipeline for approval. It is expected that foreign direct investment from the confirmed investors will exceed $2 billion in the years ahead once investors complete construction of their facilities.

|

|

Sustainable building materials have been used in the construction of bridges. |

Which key tenants have completed work on their facilities?

A number of investors are either already under operation or under construction including Schlumberger, Yokogawa, Sawafi Borets, Halliburton, Novel, OSC, Baker Hughes, Napesco, NESR, and Taqa.

What is the current status of first phase infrastructure works for Spark?

King Salman Energy Park has completed 80 per cent of work on the first of three phases of infrastructure development including roads, utilities and real estate assets over 14 sq km. In addition, construction will start shortly for the 3-sq-km logistics zone and dry port. Despite some setbacks experienced as a result of the Covid-19 pandemic, Spark has continued to make progress on construction and has realigned with its forecasted targets for the completion of Phase One in December 2021.

In April 2019, Schlumberger commenced work on a $46-million facility that will produce drilling solutions for the regional energy industry, adding 260 jobs to the workforce. Yokogawa, another anchor investor in Spark, has completed construction on its new high-tech equipment centre. OSC is building an oil and gas industry user supply base with an investment of $570 million to accelerate the localisation in Spark and the growth of small and medium enterprises. They will be providing ready-to-use factories with the latest specifications, along with a range of integrated services and logistical solutions.

What is the scope of works under the current phase of development?

Under the current phase of development, we are seeing the construction of the main central utilities, five buildings in the administrative plot, all infrastructure utilities and roads serving tenant plots that are mostly along the core spinal road, highways and bridges serving the commute to/from Spark, and the external utility connections that extend power and water supplies.

|

|

A rendering of an adminstration building at Spark. |

When is the second phase expected to be rolled out and what will be the area and scope of works involved?

The second phase has been partially accelerated due to demand, by adding more industrial clusters and expediting the logistical zone infrastructure and dry port. The masterplan is being revisited for further acceleration in alignment with market potential.

Are there any special requirements made of contractors in terms of the type of industrial projects that the infrastructure will be required to support?

Saudi Aramco’s standard practices have been applied across the development, in addition to innovative solutions such as environment-friendly sand stabilisers and strategically positioned sand fences, and smart Personal Protective Equipment (PPE) that reduces risks during facility commissioning activities.

Spark is utilising the latest advances in technology to create a world-class energy ecosystem, including sustainable building materials. Where are these materials sourced from?

Already recognised as the first industrial city in the world to obtain LEED (Leadership in Energy and Environmental Design) silver certification from the US Green Building Council (USGBC), Spark has deployed multiple innovative construction solutions that promote sustainability – many of which are being adopted in Saudi Arabia for the first time, as we spearhead a drive for more environment-friendly building technologies that support the Circular Carbon Economy framework.

Spark has become the first entity in the kingdom to utilise Podzolic green concrete, whereby recycled material produced as a byproduct from local manufacturing is utilised as a partial replacement to cement. Capturing locally-produced waste materials and re-employing them in construction will help reduce landfill disposal by 5 million tons annually. Spark is also the first entity in Saudi Arabia to utilise ConXtech steel connection technology for a commercial building. This cutting-edge innovative solution allows for molecular construction rather than welding and bolting beams together allowing for increased efficiently, lower material wastage, improved site safety and less construction time.

In the Middle East and North Africa region, Spark pioneers the deployment of glassfibre reinforced polymer (GFRP) rebar as a non-metallic replacement for epoxy steel reinforcement in bridge decks. The utilisation of GFRP rebar manufactured by Mateenbar reduces the weight of steel reinforcement on bridges by 70 per cent providing a lighter, stronger, corrosion-free material with low thermal conductivity, reducing waste and maintenance leading to longer-term returns on investment.

We have also pioneered the first application of liquid nano clay (LNC) which works to enrich desert sand to enhance its fertility. The process allows nanoparticles of clay to be bound to sand particles creating a soil fertile enough to allow agriculture to thrive in arid climates, reducing irrigated water consumption by 25 per cent and carbon emissions by an average of 15 tons/hectare annually.

Is Spark stipulating that its tenants use green building materials in the construction of their facilities?

Spark supports kingdom-wide initiatives to deploy sustainable solutions and practices, and we encourage our tenants to adopt environment-friendly practices in line with the nation’s vision for sustainability. The kingdom has set out clear priorities to support localisation through Vision 2030 which includes not only the workforce but also assets, goods, services or technology. Both local and foreign investors must work to include a specific percentage of locally sourced components in order to meet key targets for investing in the kingdom.

How has Spark ensured safety of workers and continuity of work on site during the Covid-19 pandemic?

Spark has implemented the highest standards of health and safety regulations as mandated by the Ministry of Health on both Saudi Aramco team and contractors. These include implementing social distancing measures, mandating wearing masks on all employees, minimising gathering and depending on online meetings and many other precautions.

The Covid-19 pandemic has impacted the project by delaying materials delivery to site, lack of manpower supply, and overall slowing in progress. Nevertheless, Spark’s management has taken action to minimise the impact of the pandemic such as sourcing alternative materials from local suppliers and changing the method statement of some of the construction activities such that it will be heavy equipment based rather that labour-based, minimising the number of labourers needed.

.jpg)

(1).jpg)