The secondary treatment unit at Tubli STP uses the Hybacs technique from Bluewater Bio.

The secondary treatment unit at Tubli STP uses the Hybacs technique from Bluewater Bio.

Bahrain is making significant strides in its wastewater management infrastructure with major projects currently in progress around the country to address key water conservation issues. These initiatives will not only increase treatment capacity but also introduce cutting-edge technologies for a more sustainable future.

At the heart of these developments lies the Tubli Sewage Treatment Plant (STP), which is in the midst of its fourth phase of expansion. The main contractor on the project is a consortium of Germany-based WTE Wassertechnik, Tecton Engineering & Construction and Azmeel Contracting Company, with Bahrain-based Cebarco being the civil subcontractor.

The Phase Four project, which is around 80 per cent complete, comes as part of a major upgrade of the largest wastewater treatment plant in Bahrain. It aims to enhance the performance of the Tubli centre for the production of treated water, double its daily capacity, from 200,000 cu m per day to 400,000 cu m per day, and meet needs for irrigation and landscaping.

|

|

The tight space around and inside the furnaces and the high ambient temperatures required great skill from the brickwork fitters. |

The construction of the plant, reportedly costing BD78 million ($207 million), is being jointly funded by Saudi Arabia and Kuwait, as part of the Gulf Development Programme.

The tertiary treatment plant includes a sand filter unit, an ozone gas sterilisation system, a chlorine sterilisation system, a balance basin and a sludge incineration plant.

A key element of the Tubli expansion is the construction of a new sewage sludge incineration plant. This facility, complete with dewatering and drying capabilities, will enable efficient and environmentally responsible disposal of sludge.

A recent milestone achieved on the project was the successful completion of the brickwork lining for two high-performance fluidised bed furnaces – crucial components for the incineration process. This involved installation of around 400 tonnes of lining material over a period of five months for the high-performance furnaces. These furnaces, which have a diameter of around 5 m and a height of around 20 m, can withstand extreme temperatures reaching 1,000 deg C.

The tight space around and inside the furnaces and the high ambient temperatures in Bahrain required great precision and skill from the fitters, according to WTE.

|

|

The tight space around and inside the furnaces and the high ambient temperatures required great skill from the brickwork fitters. |

The special refractory bricks were laid in three layers on top of each other on the furnace wall to ensure a stable and durable brick lining. Each brick had to be placed in exactly the right position so that there were no gaps and the structure remains stable. The next step was the controlled dry-out of the brickwork to vaporise the remaining water.

According to WTE, sewage sludge is incinerated at temperatures between 700 deg C and 980 deg C in a fluidised bed furnace, where it is placed in a sand bed. Preheated air is then blown into the furnace from below, causing the sand material to fluidise.

The hot sand in the furnace causes the remaining water in the sewage sludge to evaporate, while the remaining organic mass of the sludge burns completely.

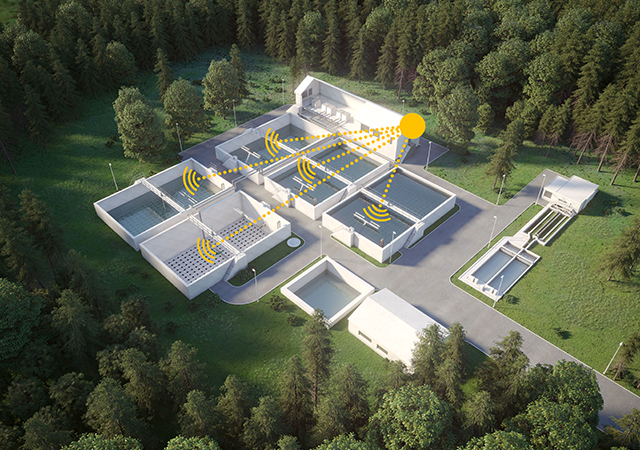

The secondary treatment unit at Tubli STP uses the Hybacs technique, a patented Hybrid Activated Sludge process from UK-based Bluewater Bio to improve the quality of the treated water.

The project deploys proprietary Smart reactor units that stimulate a special and specific bacterial pattern with a high biological activity that has the ability to deal with different levels of organic materials.

|

|

Civil work was carried out by Bahrain-based Cebarco. |

Earlier, leading geotechnical specialist contractor Keller tackled the challenge of installing a 900-mm-diameter secant pile wall for the plant using the segmental double-wall temporary casing to the full depth of 28 m and through 16 m to 17 m of limestone rock.

The double-wall casing was proposed due to its past successes in Bahrain in doing such works. This also enabled the installation of stone columns very close to existing live gas pipelines and in very constrained work space between many construction activities in progress, according to Keller.

The main pumping station, which is approximately 26-m deep and made of 2.6-m-thick reinforced concrete, is one of the most important components of the project, which collects sewage water from various regions in the country

The project includes a collection room for wastewater streams 21 m underground and a pump 25.1 m underground that will receive wastewater flows from the collection room.

The construction includes several buildings for laboratories, a workshop, the plant’s administration and the Sanitation Affairs Directorate.

North Sitra wastewater treatment

Meanwhile, progress is also being made at Bahrain’s North Sitra wastewater treatment works, where Bluewater Bio is responsible for all aspects of engineering, acting as EPC contractor and technology supplier, through the provision of its advanced treatment technologies, Hybacs and FilterClear (high throughput multi-media filtration). These advanced solutions will significantly improve the quality of treated wastewater.

The $42.6-million contract, awarded earlier this year, is scheduled for completion in 24 months. Following the upgrade, the North Sitra plant will be able to process double its current capacity, reaching 30 million litre per day of treated wastewater.

.jpg)

(1).jpg)