Robot-based solutions reduce operational costs and improve warehouse efficiency.

Robot-based solutions reduce operational costs and improve warehouse efficiency.

The automation of material handling is rapidly expanding within the logistics domain, driven by factors that span from budget management to ensuring health and safety standards. Organisations throughout the supply chain are actively seeking ways to lower operational and production costs while decreasing manual labour. Enterprises are utilising automation to boost output and streamline operations, while also mitigating the impact of fluctuating workforce availability.

The global material handling equipment market is expected to reach $369.01 billion by 2032 while projections indicate that the automated material handling market in the Middle East and Africa (MEA) region will reach $1.89 billion by 2026. Middle Eastern nations, notably Saudi Arabia and the UAE, are shifting towards economic diversification, directing investments into specialised manufacturing zones and boosting tourism to enhance non-oil revenue sources. The two nations hold the largest market shares in material handling in the region and are investing heavily to become prime hubs for logistics and warehousing. With the surge in industries, from construction to e-commerce, in both these countries and the wider Gulf region, automated material handling is advancing to enhance service quality.

These developments and a rise in data analytics are reshaping the material handling sector with five key trends emerging:

.jpg) |

|

Swisslog’s PowerStore pallet shuttle system boosts storage capacity. |

Heavy-duty products

In the construction sector, material handling presents unique challenges, especially in managing bulky and heavy items like building materials and large-scale products. Some materials found on a construction site are toxic and others contain flammable gases. Additionally, various construction materials may degrade or become less effective when subjected to diverse weather conditions. Demand for bulk material handling systems is likely to grow to $6.9 billion in 2033, recording a CAGR of 2.5 per cent in the next decade.

Warehouses dedicated to construction materials require robust systems for efficient storage and retrieval, often incorporating heavy-duty cranes and advanced conveyor systems. These facilities must balance spatial efficiency with the ability to handle a diverse range of materials, from delicate fixtures to sizable structural components, ensuring safety and speed in a sector where time and space are paramount.

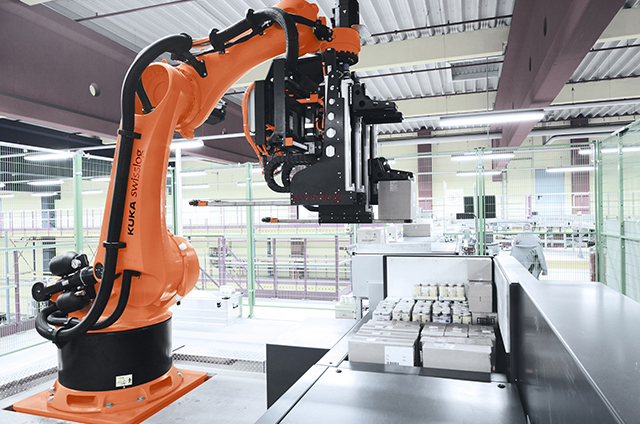

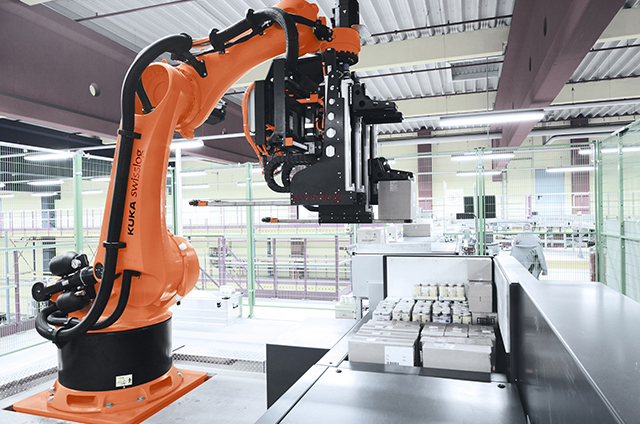

Robotics

Robots streamline supply chain operations, ensuring zero-defect processes, heightened productivity, cost reduction, and meeting escalating customer demands. It’s expected that by 2025, 45 per cent of all manufacturing will be performed by robotic technologies, according to Mordor Intelligence.

• Pallet customisation: Tailoring pallets for streamlined store restocking is gaining traction. Until lately, retailers had few choices for mixed-case pallets that align with store layouts. However, recent years have witnessed manufacturers like Swisslog introducing palletising systems that promise to broaden technology adoption.

• Product selection automation: Robotic arms have historically struggled with the diversity in size and form of items to be picked. While advances have been made in robot vision and gripping, this has not yet translated into widespread use. Presently, efforts are geared towards refining these robots to handle easily and reliably graspable items, which is expected to improve performance in certain applications and rekindle interest in these robotic solutions.

The investment in robotics is driven by businesses aiming to minimise infrastructure, granting warehouses the flexibility to relocate, reshape, and adapt at a moment's notice.

Maximised space storage solutions

As e-commerce and logistics pressures intensify, maximising space utility has become a critical imperative. This approach, which utilises advanced automated robots, vertical storage solutions, and intelligent inventory systems, aims to optimise space utilisation. Ultra-high-density storage systems enable warehouses to store a large volume of small parts, increasing storage density while maintaining flexibility. Such strategies empower organisations to streamline their operational flow and reduce expenses associated with extensive storage infrastructures.

Swisslog's AutoStore system is at the forefront of this innovation and integrates a robotic fleet that orchestrates a bin grid system, ensuring maximum space utilisation. The robots seamlessly execute storage and retrieval tasks with accuracy and swiftness. AutoStore's scalable structure is designed to adapt to growing business demands, while its instantaneous inventory monitoring and order execution capabilities elevate operational transparency and performance. Its compatibility with various item dimensions and forms renders it a highly versatile tool.

Sustainable warehouse practices

With 2023 being the Year of Sustainability and COP28 being hosted in the region, the push for sustainable logistics continues, with 75 per cent of shippers prioritising more eco-friendly shipping methods. Electrified automation solutions, including robotics, are significantly energy-efficient, using as little as 0.1 kW per hour. These can be powered by sustainable and renewable sources, such as a solar-powered warehouse automation system.

Software-driven automation

An increasing number of warehouses are transitioning from fine-tuning standalone systems to using a mix of automation technologies that work together.

This evolution is leading to the development of consolidated platforms that integrate diverse control modules. These platforms will be like conductors of an orchestra, making sure that the people, processes, and machines all work together smoothly.

Predictive analytics is also changing the way warehouses work. This technology uses machine learning and data analysis to predict things like when equipment will need to be repaired, how much demand there will be for products, and whether there are any quality problems. More and more warehouses are adopting smart, sensor-driven systems with cloud-based analytics for data collection.

Such coordinated systems promise to enhance not just individual operations but the efficiency of the entire warehouse ecosystem.

.jpg)

.jpg)

.jpg)

-(10).jpg)