The Salwa vacuum pumping station ... the largest of its kind in the world.

The Salwa vacuum pumping station ... the largest of its kind in the world.

Vacuum sewerage systems are a low-cost, environment-friendly solution for property developers and towns looking to install sewers or replace redundant sewerage infrastructure in difficult and expensive areas (primarily coastal areas with a high-water table, says Flovac, an expert in the design, supply, installation and operation of such systems.

Many environmental authorities no longer allow communities to remain on septic tank systems, says the company.

“These have been causing tremendous damage to the surrounding areas and impacting on the health of residents. Regulatory changes related to boat discharges have also led to new sewer systems at many marina precincts,” says a spokesman for the company.

|

|

Hilton Salwa Resort ... Flovac has supplied a vacuum system to handle its high flows. |

These systems reduce a town’s reliance on electricity and can operate efficiently with water-saving technologies. They can reduce the risk of infiltration from stormwater and ground water, have low operational costs due to advanced monitoring technologies and can be installed quickly with little disruption to residents and businesses, he says.

The company’s vacuum sewerage systems have been used worldwide including in the Gulf, with its most recent project having been the Hilton Salwa Beach Resort and Villas, which is poised to become one of the largest resorts and residential projects in Qatar.

The resort and villas complex, constructed on 257 acres of land in the Salwa region, includes a water park, marina, dive centre, cinemas, pools, a health club, spa and retail space. In addition to the rooms and suites in the main hotel building, the resort also includes two small ‘villages’ of family villas.

Flovac was asked to design and supply a vacuum system that would be able to handle the high flows that will ultimately be handled by the resort.

“The vacuum system needed to facilitate not only the hotel but also residential areas, restaurants and the marina. The client was aware of the good work which Flovac had done at Reef Island in Bahrain and was particularly impressed with the monitoring system that had been installed,” says Willem Gooren, one of the founders of Flovac, who had managed the project.

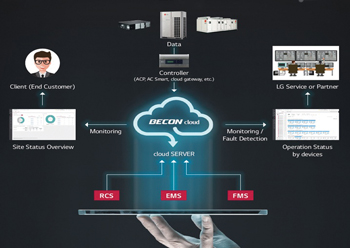

“The monitoring allows operators to see exactly what was happening anywhere in the network including the operation of the vacuum pump station,” explains Gooren, who was based in the Middle East for extensive periods during the project’s establishment and finalisation.

Gooren explains that vacuum systems are ideal for installation in sandy soils, especially areas where there is a high water table, as all of the pipework is installed at a shallow depth in the ground.

A stepped profile within the pipeline design allows for some utilisation of gravity while keeping the pipe shallow.

“Installation of vacuum mains is a lot faster than the installation of gravity sewers as there is less requirement to dewater or pre-load the land. HDPE pipe is used often when installing in hot climates and where soil conditions are unstable,” he adds.

According to Gooren, the use of a Flovac system was vital to ensure that there would be no potential leaks from the system. “As all vacuum pipework is under a negative pressure, sewage cannot leak from the pipe in the event of a break,” he says.

He points out that Salwa vacuum pump station was one of the largest stations in the world. Housed in a dry and air-conditioned environment, its two large collection tanks are connected to five large Busch Mink MM 1202 vacuum pumps.

According to Flovac, a single vacuum pump station can connect up to 10,000 people.

Headquartered in The Netherlands, Flovac has its engineering, operations and productions facilities across the globe including at a number of core centres located in Germany, Poland, Slovenia, Bahrain, Australia and the US.

.jpg)

(1).jpg)