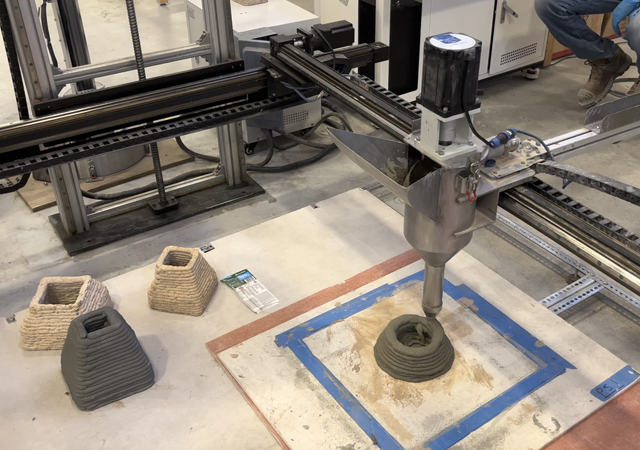

J-pavers at work on 6-m-wide and 2.5-m-wide pavements (below) in Switzerland.

J-pavers at work on 6-m-wide and 2.5-m-wide pavements (below) in Switzerland.

SUMITOMO Construction Machinery Company has developed a new screed that is said to offer significantly more paving width than conventional screeds.

The J-paver screed offers maximum paving width of more than two-and-a-half times the length of the main screed, compared to conventional screeds which allow up to only twice their length, according to the company.

Fitted with the J-paver, Sumitomo’s pavers enable construction of pavements of up to 7.5 m wide possible without the use of bolt-on extension screeds or ex screeds.

The J-paver series are user-friendly, green-friendly, easy to repair and of high quality, says a spokesman for the Japanese firm. The series, hitherto available with a maximum paving widths of below 6 m, boasts a market share of over 70 per cent in Japan.

Fumio Goto of Sumitomo says the J-paver is totally different from the conventional screeds. “Behind the main screed, which is fixed to the side arm, two rear screeds are located in front-back direction, instead of being parallel. They are hydraulically driven to realise a stepless extending range of paving width, over 2.5 times the length of the main screed, and the high paving quality required for this task.”

The J-paver series includes J-paver 2360 (maximum paving width 6 m without ex screeds) and the J-paver 3075 (maximum paving width 7.5 m without ex screeds).

The 2360 extends the range of road projects that can be handled, allowing paving of roads from as little as 2.3 m to 6 m wide, by only using one machine and extending the rear screed. The 3075 is 3 m, can be extended to 7.5 m and to a maximum paving width of 9 m by adding ex screeds.

“This is a world-first screed which can pave up to two lanes on a highway without ex screeds,” the spokesman claims.

The J-paver, which has a well-balanced triple screed, has four large guide pipes increasing the rigidity of the screed. The compaction mechanism adopts Sumitomo’s original STV system. This ensures even paving.

The compaction mechanism consists of existing tamper and vibrator, and the strike-off (S) system. The strike-off system provides an optimal material flow into a screed plate and pre-compacts it, achieving a smoothly finished surface, even using material with poor workability.

Users can opt for either electrical and LPG screed heating. In the LPG option, the heated air burner system with specially designed duct, heats the screed plates evenly in a short time. This results in a dramatic improvement in the lifespan of the screed plates.

There are also options of either selecting a shutoff timer to avoid overheating of the screed plates, or an automatic temperature controller to consistently keep the set temperature. These allow an energy-saving heating, compared to the electrical type of heating.

Paving thickness with the J-paver can be adjusted manually by a simple operation of a switch, or automatically using grade controller, slope controller and sensors.

The 2360 can be fitted to Sumitomo’s wheel-type HA60W and crawler-type HA60C pavers while the 3075 is suited to the HA90C. These screeds greatly improve quality, environmental performance, manoeuvrability, serviceability, and reliability, says Goto.

Goto says in developing the J-paver Sumitomo has focused on creating a screed that achieves a large pavement width without the use of ex screed. “This concept saves labour and manpower, and easily manages an ex screed, enabling efficient operation with safety, and greater accuracy of the pavement,” he says.

With regard to the maximum pavement width, he says that when the paving width increases, the auger operation width increases as well. And depending on the width, segregation of the asphalt mixture will occur, resulting in an uneven pavement. Sumitomo believes the maximum paving width possible is 9 m, while considering paving accuracy.

The J-paver enables fleet owners to reduce the number of machines in their fleet while increasing the utilisation rate.

For the construction of narrower roads (2.3 m), Sumitomo is developing a mini paver equipped with a J-paver such as the 1741.

The J-paver series is now dominating the market in Japan, where more than 2,000 pavers with the 2360 are in operation. Construction without the ex screed is now commonplace, Goto says.

“This concept of J-paver is becoming recognised not only in Japan but in Europe, China and India as well,” he adds.

Sumitomo plans to expand its sales throughout the world, and will be aggressively promoting these machines that enable the construction of roads with up to 7.5 m-wide pavements without the ex screed.

.jpg)