SLC's laboratory ... stringent testing facilities.

SLC's laboratory ... stringent testing facilities.

Wasteful energy consumption is costing nations millions of dollars through the need to build more power stations to meet demands. In addition, these power stations pollute the environment through their emissions.

Reducing consumption has, therefore, become of vital importance to save on investments that would be required for the construction of additional units, while also to protect the environment from increased emissions, says the Riyadh-based Saudi Light Company (SLC).

High-frequency electronic ballasts can play an important role in reducing energy consumption while providing more efficient lighting, says the company.

''High-frequency electronic ballasts represent state-of-the-art technology in the manufacture of lights, particularly fluorescent ones,'' says a spokesman for the company. ''These hi-tech ballasts also represent a logical and much-anticipated development in the field of lighting.''

Elaborating on their advantages over conventional ballasts, he says: ''Traditional ballasts heat up when ignited, thus emitting heat which represents lost energy, whereas high-frequency electronic ballasts ensure higher lighting levels while reducing the consumption of energy.

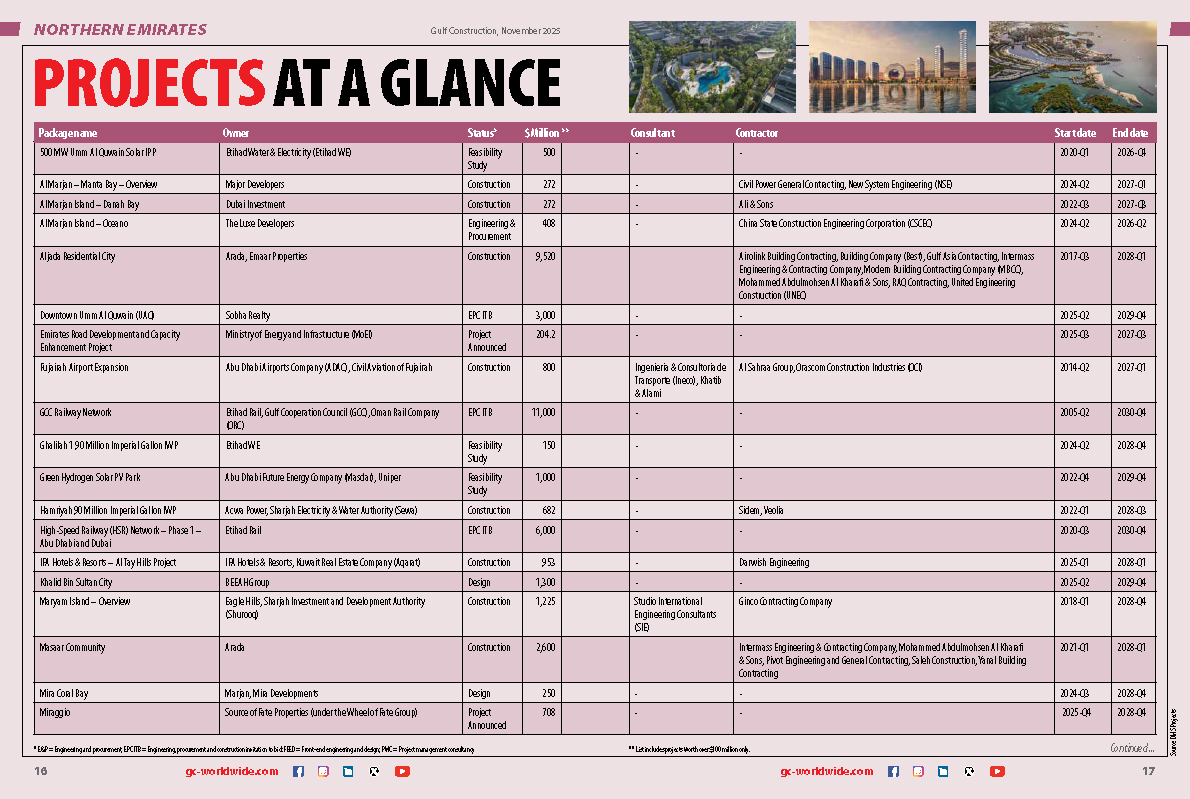

''Table 1 compares the performance of electronic ballasts with traditional ones in a typical 80 sq m room. It indicates how electronic ballasts produce savings of 850 Watts on energy, representing a reduction of 34 per cent in overall consumption. Just imagine the amount of energy saved in a multi-storey building!

''It may be argued that the initial costs of the lamps equipped with electronic ballasts are nearly 50 per cent higher than those with traditional ones. However, the overall cost of the lamps with electronic ballasts is only 10 per cent higher than the traditional ones. This additional cost is easily compensated when taking into account the overall costs of the room air-conditioning load.

''This is because energy that is wasted produces greater heat-up in the same 80 sq m room. Hence, it would require an additional 5 per cent more cooling load to air-condition the space. Installing electronic ballasts means the bill for air-conditioning of the whole building will be effectively reduced by as much as 30 per cent.''

Pioneering firm SLC is one the largest specialised lighting manufacturers in the Middle East, offering products that reduce the consumption of energy and ensure higher levels of reliability and performance in line with international standards and the Kingdom's efforts at saving energy.

SLS ensures that all its products are tested before they reach its clients.

|

Comparison chart |

The company's lighting systems comply fully with the standards set by the Saudi Arabian Standards Organisation (Saso), ensuring the highest level of safety, reliability and performance, according to the spokesman.

''The lights are tested in highly stringent conditions to ensure their components are safe, offer high performance and are capable of resisting high temperatures, soil, dust and rain,'' he says.

The company's products conform to international quality standards, which means that all the components used their manufacture are world-class, he adds.

According to the spokesman, SLC strictly follows certain criteria in its manufacturing process. These include:

(5).jpg)

.jpg)