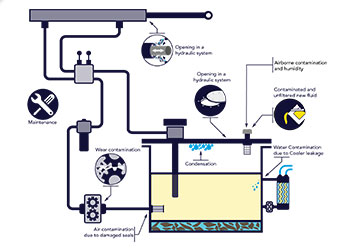

Contamination sources in hydraulic systems.

Contamination sources in hydraulic systems.

In industries where high-value and production-focused equipment operate, it’s all about maximising uptime, productivity and efficiencies. Yet, oil – which one of the most important components of an industrial system - is too often seen as a consumable and doesn’t receive the attention it deserves and requires.

Without a lubricant, your gearbox would get damaged within no time and without oil, a hydraulic system doesn’t even work.

Contaminants such as particles and water can and will have negative consequences on the functionality of your systems. At first, the performance, productivity and efficiencies of your machines and assets decline and thereafter unexpected component breakdowns will occur.

|

|

|

Approximately 70 per cent of the machine failures are caused by surface degradation, also known as mechanical and corrosive wear. It’s known that mechanical wear such as abrasion, erosion and fatigue impact the productivity and efficiency of machines and eventually lead to component breakdowns and costly downtimes.

Water should not be underestimated as it is a serious type of contamination that leads to issues like fluid oxidation, internal surfaces corrosion, additive depletion and other fluid failures. These types of failure will accelerate the degradation of the oil.

These contaminants can also cause secondary contamination such as acids, sludge and varnish by-products.

So where do these contaminants come from?

Contamination can originate from various sources:

- New systems and components are usually contaminated during the manufacturing processes;

- New oil is often dirty oil as, in almost all cases, above the target cleanliness levels are required for the systems/assets;

- Contamination ingress through damaged seals;

- Contamination (particles and moisture) ingress through filling caps, ports and breathers;

- Internally generated contamination – such as through friction, wear, abrasion, erosion and oxidation.

|

|

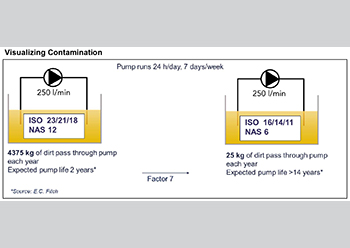

Visualizing Contamination. |

There are two commonly used standards in the industry - the ISO 4406 and the NAS 1636 - to measure the particle contamination level in a fluid.

Developed by the International Organization for Standardization, the ISO Range Code is the most used cleanliness code. The ISO 4406 code records the cleanliness level of a liquid by three numbers.

Each number refers to an ISO Range Code, which is determined by the number of particles larger than 4, 6 and 14 micron, respectively present in 1 ml or 100ml of fluid.

The aim is to ensure that the oil and your system stays in optimal conditions as long as possible since this will directly result in:

- Extended machine reliability;

- Fewer breakdowns;

- Less frequent oil changes; and

- Longer remaining life of components and oil.

This will ultimately result in a higher return on investment.

|

|

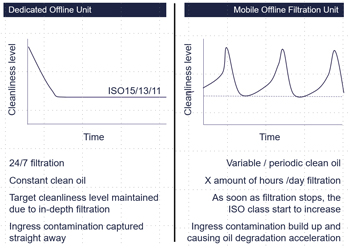

Mobile vs Permanent filtration |

Although inline full flow filters are an essential part of a system, most of the time they are not capable of keeping the oil at or below the target cleanliness and moisture levels.

The solution here is to adopt additional micro-filtration to achieve these targets as these units continuously improve the oil quality by reducing contamination levels.

So, what are the measures that can be taken to implement a contamination control strategy?

- First, set a target. Every component has a manufacturer-specified ISO cleanliness and recommended target moisture levels. Aim to achieve this.

- Second, take action. Install desiccant breathers that will absorb particles and moist as well as adequate additional filtration.

- Third, measure contamination levels. Take samples on a regular basis to measure and evaluate effectiveness of your actions.

There are two ways to implement a contamination control strategy using additional filtration: mobile and dedicated.

|

|

Mobile offline filtration |

Mobile offline filtration: Also known as periodic filtration, this is a good start to remove/degrease the contamination levels in the oil in a system.

It’s an economical way to filter multiple assets with the same filtration unit, especially when you want to filter but have budget restrictions. It’s the ideal choice/solution for pre-filtering new oils as they arrive at your plant or facility. This method is often used for periodic filtration of less critical assets or where not a great deal of contamination build-up is expected.

Dedicated: Dedicated filtration is especially used in critical applications where downtime and the high associated costs have a significate impact on the productivity and performance of the machines.

Keeping the contamination levels as low as possible is essential for the proper functionality of the system components.

CONCLUSION

Machines/systems require certain cleanliness levels to operate properly. Micron-size particles and very small amounts of water cause most of the failures in assets like hydraulic systems, gearboxes, reducers and pumps. Therefore, it is of utmost importance to keep the contaminants out of the lubricants as much as possible.

Implementing the right contamination control strategy will result in:

- Increase of overall equipment reliability;

- Reduction of downtime and maintenance costs, thus saving money;

- Reduction of your footprint on the environment.

This article is supplied by MH Hydraulics

|

|

|

.jpg)

(1).jpg)