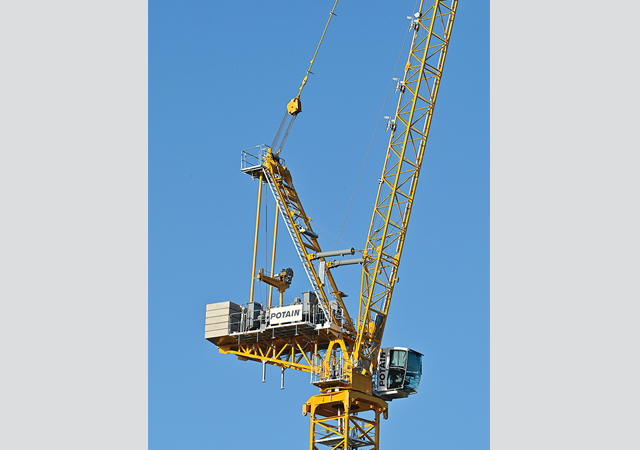

Three Raimondi MRT159 flat-top tower cranes are at work on the JVC building site.

Three Raimondi MRT159 flat-top tower cranes are at work on the JVC building site.

Raimondi Cranes, a leading Italian manufacturer of tower cranes, has solidified its position in the GCC having secured key contracts in two of the largest markets in the region.

In Saudi Arabia, the crane manufacturer last month marked the sale of 70 machines which are deployed in a variety of jobsites across different provinces of the kingdom. The machines are supporting projects in a multitude of sectors, including healthcare, hospitality, residential, education, and critical infrastructure development.

“The tower crane sector is experiencing a surge of demand in Saudi Arabia, fuelled by the economic diversification efforts outlined in Vision 2030. The kingdom, positioned as a hub for construction innovation and growth, is a valuable market with advanced planning,” says Wael Hasan, General Manager, Raimondi Middle East.

“This newest milestone is a great moment for us. We’re looking at the next several years in Saudi Arabia as very favourable for the heavy machinery segment,” he adds.

Raimondi's portfolio in Saudi Arabia includes a range of models designed to cater to various client needs and project requirements.

“Among the most popular models, the Raimondi MRT159 and MRT294 present excellent lifting capacities, versatility, and ease of installation,” states Hasan, noting that the company’s current product portfolio includes both luffing jib and flat-top tower cranes with maximum lifting capacities ranging between 4 tonnes to 20 tonnes.

“As we celebrate this milestone, we are committed to further strengthening our presence in the kingdom; by continuing to innovate and provide unparalleled service to our clients,” stated Luigi Maggioni, Group CEO, Raimondi Cranes.

UAE

In the UAE, Raimondi cranes, including the MRT159, have been deployed at various projects in Dubai and Sharjah.

|

|

The three MRT159s are currently freestanding at heights of 51 m, 45 m, and 42 m. |

Among the latest successes in Dubai, Raimondi Middle East has deployed three MRT159 flat-top tower cranes for a 25-storey residential building in Jumeirah Village Circle (JVC) as well as five LR213 luffing jib cranes for a prominent two-tower residential high-rise being built at the intersection of Downtown Dubai and Business Bay.

The three MRT159 tower cranes, which were installed at the 25-storey building in JVC during March this year, will remain onsite for approximately 18 months.

Erected with jib lengths ranging between 38 m and 44 m, the MRT159s are currently freestanding at heights of 51 m, 45 m, and 42 m. Boasting a maximum lifting capacity of 8 tonnes, the machines are equipped with a 45kW hoisting gear, lifting at a maximum speed of 136 m/min and have a drum capacity of 840m.

“Due to the site location and its congested nature, we had to carefully plan the installation of each crane, including operational and positioning aspects to ensure maximum site safety and efficiency,” Hasan explains.

One of the key characteristics of the MRT159 is ease of installation, which enabled it to be erected within a day; the model arrives onsite with all parts pre-assembled, ropes passed and rope connections installed, facilitating field procedures.

“Based on site progression, each machine will be climbed in three stages to reach the final heights of 102 m, 105 m, and 111 m; operations that will be carried out by our team,” says Hasan.

.jpg) |

|

Five Raimondi LR213s are at work on the two- tower development in Dubai. |

Meanwhile, Raimondi has installed its LR213 cranes in March at the new two-tower development, which spans over 1.42 million sq ft and features a total of 1,030 units. The LR213 units are all currently freestanding at 45 m with jib lengths ranging between 44.5 m and 55m, says the company.

Based on the progress of work on site, four out of the five luffers will be externally climbed to reach the impressive heights of 145 m and 190 m. Equipped with a 55kW hoisting winch with a drum capacity of 880 m, the cranes lift at a maximum speed up to 104 m per minute, it states.

“By renting these five Raimondi LR213s, we continue to prove our strong flow of commercial activity and active involvement in the development of the region,” remarks Hasan. “Participating in this high-profile project underscores our fleet reliability and efficiency, while reflecting our commitment to providing solutions that cater to the complex urban construction projects.”

He points out that the 14-tonne model offers great lifting capacities and flexibility, facilitating the efficient handling of heavy materials and components, streamlining the construction process and enhancing site safety.

These cranes were installed with meticulous planning and precision, ensuring minimal disruption to the surrounding areas while maintaining the highest standards of safety and operational efficiency, he adds.

Hasan states that the LR213 had been selected to meet the specific requirements of the project’s contractor. Also, it will help ensure timely and safe execution, while avoiding collision and overfly of surrounding properties; thus making it ideal for high-rise construction in densely populated areas, he adds.

Raimondi Middle East’s technical team will continue to provide onsite support throughout the project’s duration, including the several climbing stages to allow the crane to reach the final heights, as well as the dismantling procedures.

The LR213s will remain onsite for approximately 18 to 22 months.

.jpg)

(1).jpg)