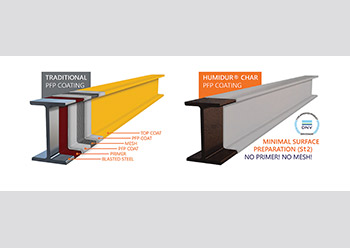

Acotec, a Belgium-based industrial coating company, has launched its ‘revolutionary’ Humidur Char, a two-component, solvent-free, 100 per cent solids, polyamine cured epoxy passive fire protection (PFP) system, which offers anti-corrosion and fire resistance properties by intumescent action in just one coat compared to the traditional PFP coating process that requires up to five coats.

Developed by Acotec, Humidur Char has been thoroughly tested and received Type Approval from classification society DNV ahead of its launch. It has also passed an extensive test programme and provides protection against (high heat flux) jet fires, pool fires and can resist gas explosions, says the company.

Acotec points out that another key benefit of Humidur Char is that it can be applied in one layer on minimum preparation standards, with no primer nor mesh required and would still provide the essential passive fire protection on the structural steel, used within the global oil, gas and chemical industry.

Not only does this revolutionary coating enable improved cost management, moreover it significantly reduces the manhours up to 50 per cent, it adds.

CEO Wim Schalley says: “Humidur Char is a revolutionary one-coat solution. Extremely easy to apply, it can be trowelled or sprayed straight onto the structural component, which does not need to be grit blasted. Spray application can be conducted with standard plural pumps, so no expensive and complicated specialised PFP pumps are required.”

With a wide application window in terms of humidity (maximum 95 per cent), Humidur Char can be applied at any location in the world.

(5).jpg)

.jpg)