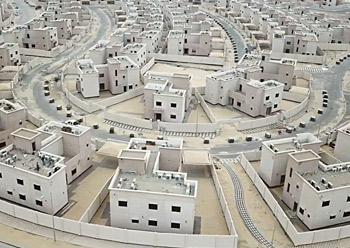

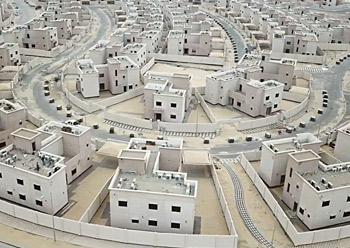

QDC has carried out several housing projects in the kingdom.

QDC has carried out several housing projects in the kingdom.

Qanbar Dywidag Precast Concrete Company (QDC), one of the largest precast concrete manufacturers in Saudi Arabia, is keenly eyeing the promising Riyadh market, with a view to addressing the requirements of the mega projects taking shape in the Saudi capital.

Among the major projects coming up in Riyadh are Qiddiya, Riyadh airport expansion, Diriyah Gate and various Ministry of Housing and Roshn developments and the veteran precast concrete specialist is positioning itself to cater to these projects from its various facilities in the kingdom.

QDC continues to serve the construction sector in Saudi Arabia, based on its four decades of project execution excellence in the kingdom and unrivalled engineering expertise. It is already involved on projects in Riyadh for Qiddiya Investment Company (QIC), Roshn and the Ministry of Housing, among others.

“Our first project for Qiddiya was the construction of a site office with Morganti KSA. The company has also quoted on various projects at the development including interchanges, roads, plazas and substations,” Saud A Al-Ansari, Group CEO, tells Gulf Construction.

|

|

Sabic headquarters ... a landmark project. |

QDC has been approved as a building technology provider by the Ministry of Housing, which enables it to participate in most of the mega projects in the kingdom.

The company has also been approved as a certified supplier for projects by Roshn, Saudi Arabia’s national community developer. Its first project for Roshn involves the construction of 243 villas of different types (first stage) for the Riyadh North Township, with Rezaik A Al-Gedrawi Company as the main contractor of the project, he adds.

The precast concrete manufacturer was also engaged on two housing projects for the Ministry of Housing at the Murcia residential project in Riyadh’s Al-Jawan suburb with ABR Company as main contractor. This is in addition to the various housing projects it is carrying out for the ministry in the Eastern and Western regions of Saudi Arabia.

Over the past three years, QDC has completed numerous projects in the Riyadh region including Al-Rajhi university and school buildings in Qassim, King Saud University medical city, two Fitness Time buildings, Saudi Chemical plant development project, and a boundary wall for Misk city, besides the Murcia housing developments and the Qiddiya site office project.

To serve the Riyadh market, QDC has a sales office in the capital with products supplied by its two factories in Jubail and one factory in Rabigh.

“We supply the elements for our Riyadh projects from these factories, through our own transportation facilities or leased/rented ones from the available fleets in the market,” Al-Ansari says.

Its Jubail factories have an annual production capacity of 2 million sq m while the Rabigh facility can produce 3 million sq m. These facilities are regularly upgraded and expanded to ensure they are able to meet the growing demand as well as add value to the company’s products.

Al-Ansari points out that precast and prestressed concrete has evolved as the building material and solution of choice for residential, commercial, government and industrial building construction in Saudi Arabia.

“Precast and prestressed concrete is rapidly becoming the solution of choice for industrial buildings and housing projects,” says Al-Ansari. “Precast concrete is a fast way to execute projects while ensuring high quality, especially where there are repetitive elements and similar building designs; it can also reduce the cost and ensure durability to withstand harsh weather conditions.”

Al-Ansari adds that while precast and cast-in-place (CIP) construction techniques are cheaper and more durable forms of construction compared to various other alternatives, CIP is time consuming and labour intensive and its quality varies as it is not carried out in factory-controlled conditions. Compared to CIP, precast concrete offers several major advantages, he says (see Table, Page 48).

Since its inception in 1981, QDC has carried out numerous commercial, industrial, housing and institutional projects in the region, where its precast concrete systems have been the solution of choice for architects, engineers, contractors and owners.

While the company has supplied its standard precast components including beams, columns, solid and insulated wall panels, hollowcore and double-tee slabs for various projects, QDC has also met special design requirements for blast and bullet-resistant designs which can be easily accommodated with precast concrete construction.

QDC also offers a wide variety of standard precast concrete products including bollards, benches, planters, trash containers, wheel stoppers and manholes. Custom designs are also available, and all products are manufactured to the highest quality control standards.

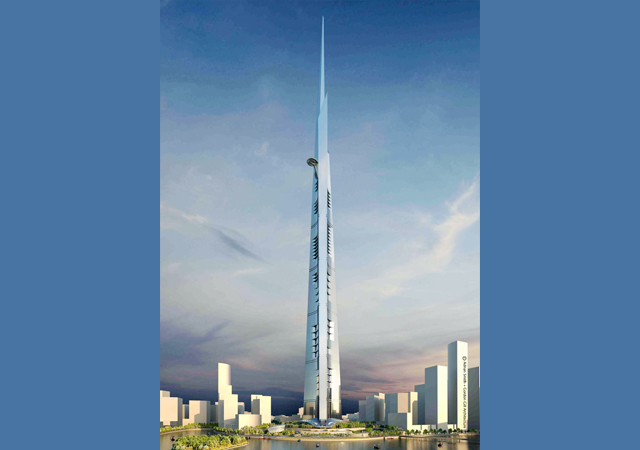

From staircases to full-frame building systems, QDC has also supplied a wide range of elements to numerous housing projects throughout the kingdom for prestigious clients including Saudi Aramco; Royal Commission for Jubail and Yanbu; Sabic; National Guard; Ministry of Defence; the Red Sea Development Company (TRSDC) – for which QDC executed its first offshore project with European Emirates Company and other different types of construction with Saudi Amana Company. QDC has also been approved as a certified supplier to Neom, Saudi Arabia’s $5-billion city taking shape in the northwest of the kingdom.

QDC was formed as a partnership between one of the leading business conglomerates in the Eastern Province, Al Ansari Holding Company (Abdul Razzaq Mohammed Qanbar Al Ansari and Sons) and one of the largest German general contractors and precast concrete manufacturers, Dycherhoff and Widmann (Dywidag). In January 2002, Al Ansari Holding became the sole owner of QDC, and Dywidag remains as a technical partner.

(5).jpg)

.jpg)