QI353 mobile impact crusher is capable of processing up to 400 tph.

QI353 mobile impact crusher is capable of processing up to 400 tph.

Sandvik, an engineering group in mining and rock excavation, metal-cutting, and materials technology, aims to revolutionise rock processing with the QI353 mobile impact crusher, the first of its 3-Series, third generation offering.

Designed to provide more uptime than any other model, the QI353 is one of the most versatile, mid-sized mobile impactors available today, says the Swedish company.

Built utilising Sandvik’s market-leading Prisec technology for primary or secondary applications, it is capable of processing up to 400 tonnes per hour (tph), whilst reducing fuel and energy consumption, it adds. ”At the core of the QI353 is a new mid-size Prisec impact crusher, which boasts the largest feed opening of 1,170 mm by 730 mm and largest rotor diameter at 1,150 mm in its class, for higher capacity and greater energy efficiency,” says a spokesman for the company.

Fitted with a host of safety features, QI353 offers three-sided 270-degree service access with ground-level maintenance points including a new rear access platform, patented rotor locking and positioning device, and a unique four-key trapped system to ensure safe inspection after the rotor has stopped turning. The spacious platforms provide safe access for service and maintenance while dust suppression spray bars and onboard water pump help minimise dust, improving operator and onsite safety.

The optional HS323 hanging screen module has now been enhanced to accept belt scales for tph monitoring on fines and stockpile belts.

The module offers multi-functionality as a one-, two or three-way split screener. It can be set up in less than 30 minutes with no additional lifting equipment required.

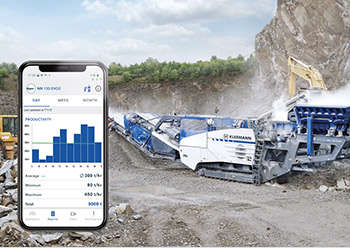

“Its operations are in your control as the QI353 is fitted with the brand new Optik intuitive user experience. This offers simplified operation controls and total integration with My Fleet telematics solution.

“With a host of easy-to-navigate features, this system allows you to maximise uptime and optimise decision-making with real-time information. It enables the operator to boost output with diagnostic assistance and enhance troubleshooting with pre-installed guides and accurate data collection,” the spokesman says. Sandvik QI353 is fitted with the latest generation fuel-efficient powerpack which provides maximum performance and cost efficiency. The double-deck pre-screen maximises crusher throughput, reduces wear costs and energy consumption.

“Initial test results have shown up to 16 per cent energy reduction in comparison with previous models. It requires 40 per cent less hydraulic oil per service and extended hydraulic oil replacement intervals, overall up to 64 per cent less hydraulic oil consumed over 10,000 hours of machine usage (subject to oil sampling),” the spokesman concludes.

.jpg)

.jpg)

.jpg)