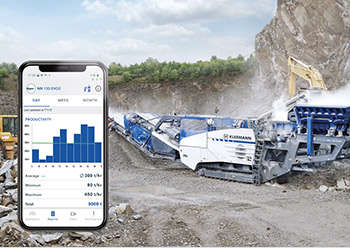

Spective Connect displays all relevant process information on the smartphone.

Spective Connect displays all relevant process information on the smartphone.

Kleemann now offers its mobile impact crushers Mobirex MR 110/130(i) EVO2 with the optional Spective Connect, which enhances work site digitalisation by displaying all relevant process information and reporting on the smartphone without the operator having to leave, for example, the excavator or wheel loader.

Spective Connect enhances the efficiency of Kleemann’s operating concept Spective, which has made control of new plants even easier and very intuitive since 2017.

Kleeman is a brand belonging to the Wirtgen Group, an internationally operating group of construction equipment manufacturers.

|

|

Mobicat MC 110(i) EVO2 has a holistic drive concept. |

The impact crushers Mobirex MR EVO2 are the benchmarks of their class with regard to output and efficiency. The plants impress with flexible application options in natural stone and recycling.

Diesel and urea fill level, fuel consumption, plant performance, current gap setting and a lot more important process data can be displayed at any time via the dashboard. In most cases, operators no longer have to leave the driver’s cab or interrupt the ongoing process. In case of a malfunction, Spective Connect displays not only a fault but, at the same time, refers to the corresponding components including troubleshooting aids.

“The smartphone can be taken to the location of the fault that occurred and support the operator step by step with troubleshooting. Spective Connect generates clearly arranged reports on consumption and plant performance as well as the plant usage. These reports can be forwarded by messenger or e-mail. The complete process is, therefore, transparent for the plant operator at any time,” says a spokesman for Kleemann.

If a fault cannot be eliminated, Spective Connect generates a service report which can be sent by Messenger to the person in charge of technology or a Wirtgen Group service centre. All operating hours, fault messages, etc are available at a glance in a clearly arranged manner and rapid help is possible.

“The offline troubleshooting aids make it possible, among other things, for a repair technician or service member to remotely support the machine operator because he can also view the troubleshooting aids. He only needs to enter the fault code and the plant type,” the spokesman explains.

The two new functions are available in the offline area and can be used free of charge without hardware. All that needs to be done is download the App.

Spective Connect is available as an option with immediate effect for the impact crusher Mobirex MR 110/130(i), the jaw crusher Mobicat MC 110(i) EVO2 and the cone crusher Mobicone MCO 90(i) EVO2. The app can be installed on iOS and Android smartphones.

Mobicat MC 110(i) EVO2 and Mobicone MCO 90(i) EVO2, with their efficient crusher direct drive, have a holistic drive concept that forms the basis for high cost-effectiveness.

Both machines of the new EVO2 generation are equipped with a patented power train. The crusher is driven directly, enabling high fuel-efficiency, via a reliable fluid coupling.

.jpg)

.jpg)

.jpg)