Portascanner Airtight 520 ... advanced technology.

Portascanner Airtight 520 ... advanced technology.

Today, and in fighting this awful coronavirus, it has never been more pertinent to test room integrity for airtightness. A building that is not airtight cannot be properly mechanically ventilated. Now is the time to ‘build tight, ventilate right’.

Until the outbreak of this global pandemic, there was plenty of frustration around the slow pace of technology adoption within the built environment. Whilst other industries had made good progress, teams of builders were struggling to meet minimum building performance standards. Inefficient processes left much room for improvement. New homes often fail to meet low-energy targets, and to satisfy residents with fundamental issues such as ease of use, summer comfort and energy costs. There is far too little building performance evaluation (BPE) happening routinely on projects to close the performance gap.

|

|

Portascanner Airtight 520 ... advanced technology. |

HOW COVID-19 CHANGED OUR SECTOR

The pandemic can be credited with pushing the construction industry in the right direction. Many processes have changed and there is no need to go back to the way it was. The technological advances that would have taken a few decades to happen, have now been achieved, due to the pandemic’s dramatic acceleration of technology adoption.

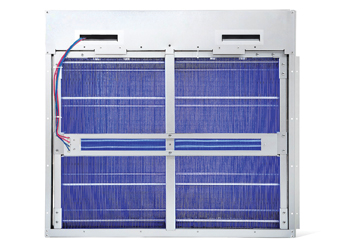

Most buildings are tested for airtightness, air permeability, and air leaks with outdated and intrusive technology, making tests difficult, time consuming and expensive. Yet it is critical to quickly locate and accurately quantify air leaks in rooms and buildings. Air leaks with a diameter as small as 0.5 mm can now be detected and quickly located with the new Portascanner Airtight 520, a unique solution from Coltraco Ultrasonics which has brought testing for airtightness, and air permeability into the 21st century.

Coltraco Ultrasonics was one of the winners of a Covid-19 emergency response grant put out by the UK Government through InnovateUK for technology to help the NHS in its efforts to prevent infection spread in hospitals and contain the virus by maintaining negatively pressurised ICU wards and ensuring their airtightness. The grant was for adapting its already award-winning watertight integrity technology into one that would be suitable for room airtight testing. In just eight months, Coltraco Ultrasonics had successfully designed and manufactured two innovative solutions to help the NHS and healthcare settings with infection control and the building sector to ensure effective ventilation through airtightness.

Following from this need to contain the spread of airborne diseases, the company swiftly saw the demand for this leak detection technology to be re-designed for the built environment.

Portascanner Airtight 520 can ensure buildings are airtight so that people can be confident that they are returning to “safe buildings” and “safe working” by properly ventilating them. This is to ensure that all ventilation systems are operating effectively, and thereby enhance indoor air quality (IAQ) which has now become a poignant issue.

No alternative leak measuring technologies measure the leak size directly, but instead infer it from pressure differences of airflow measurements, which are assumed to be taken at constant temperature and pressure, something that, in reality, is never the case. This means that alternative technologies have inaccuracies that may be minimised, but not eliminated entirely, by highly skilled operators using manual calculators.

For the first time, with minimal training, users can locate a leak, quantify the leak site, calculate the air flow rate through it, and generate an air permeability value for the room. They can then take accurate remedial action where necessary, and have full confidence in both the airtightness of the room, and the effectiveness of the ventilation in circulating clean air.

SOLVING THE PROBLEM

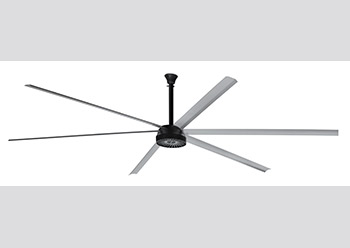

Human resources and facilities management teams are tasked with keeping buildings and spaces comfortable, sustainable, efficient, safe, healthy and well maintained, and this list keeps growing as buildings are expected to deliver more. This ‘more’ can include addressing the effects of climate change by making a building more energy efficient. ‘More’ after this pandemic will include a critical appraisal of indoor air quality.

Seventy per cent of the world’s population spends an estimated 90 per cent of its time indoors, and the World Health Organization estimates that in 2020 there were more than six million premature deaths due to air pollution, much of it attributed to poor IAQ.

Digitalisation has the power to evolve buildings from being fixed passive structures into highly interactive and richly informative systems. Homes are becoming more autonomous, so that the mechanical components inside of the spaces created can ensure that occupants are safer, healthier and more comfortable.

Air quality plays an important role in our physical and mental health, and, with Covid-19, good air filtration could mean the difference between sick and healthy, and in some cases, life and death. A fundamental requirement for energy-efficient mechanical ventilation and for effective air filtration is achieving a minimum level of airtightness in buildings. Air pollution is an increasing concern, as is maintaining an adequate level of oxygen within the built environment.

The air we breathe is made up of multiple gases, however for a human to function normally, the air must contain enough oxygen. Under normal atmospheric pressure, we normally inhale air that contains 20.9 per cent oxygen; if this falls even by one or two per cent, then functionality starts to become more laborious and the environment turns hypoxic, meaning that oxygen levels are low and could be harmful. Humans, like fires, need to have a constant and assured level of oxygen, and as we consume oxygen, more must be delivered to us.

PANDEMICS AND BUILDING VENTILATION

The design choices being programmed into buildings right now will be with us for years to come. This is a good thing because of the increased emphasis being placed upon ‘Build tight, ventilate right’. Covid-19 will not be the last pandemic disease we will suffer, but our spaces will be better prepared for when the next one strikes. Frequent, regular and periodic testing for airtightness, air permeability, and quickly locating and quantifying air leaks in buildings, so that immediate remedial action may be taken, is now possible. Indoor air quality is a key issue in building design for homes, offices, hospitals, schools and factories. Our living and workplaces, be they at our homes or elsewhere, are where we need to be safe and productive.

* Coltraco Ultrasonics exports to 125 countries, including many in the Arabian Gulf

.jpg)

.jpg)

.jpg)