Construction work is in progress on the $11-billion Amiral project, following the signing of key engineering, procurement and construction (EPC) contracts in late June by the joint venture developers Aramco and TotalEnergies for the petrochemicals facility expansion at the Satorp refinery in Saudi Arabia’s Eastern Province.

The new complex aims to house one of the largest mixed-load steam crackers in the Gulf, with downstream petrochemical units, utilities and offsite facilities. It will have a capacity to produce 1,650 kilotons per annum (kta) of ethylene and other industrial gases. The facility will also have two polyethylene lines, each with a capacity of 500 kta. The EPC contracts were for the main process units and associated utilities which will be integrated with the existing Satorp refinery in Jubail Industrial City.

The project will be located adjacent to the existing Sadara Refinery and will occupy an estimated area of 4.3 sq km.

Hyundai Engineering & Construction Co is undertaking the EPC contract for a mixed feed cracker and utilities, with a nameplate capacity of 1,650 kta of ethylene and related industrial gases, and utilities, flares and interconnecting systems that support the main packages within the facilities.

Maire Tecnimont is the EPC contractor for two polyethylene units using Advanced Dual Loop technology, with a nameplate capacity of 500 kta each, and the derivative units.

|

|

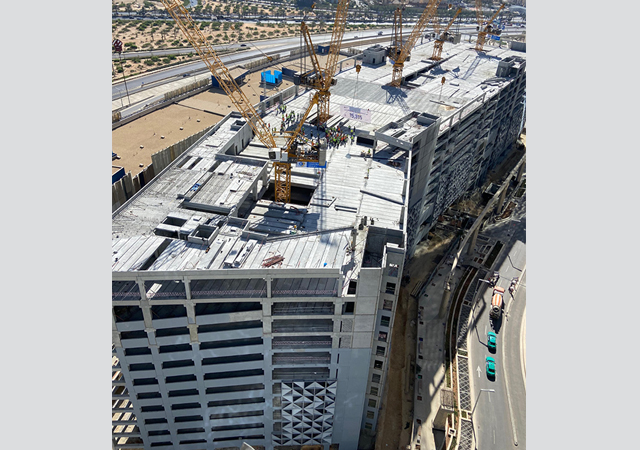

Work under way on the Amiral project. |

Other EPC contracts were awarded to Sinopec Engineering (Group) Saudi Company to set up the tank farm and Satorp integration; Gulf Consolidated Contractors Company for the transfer pipelines; Mohammed Ali Al-Suwailem Trading and Contracting Company for industrial support facilities; Mofarreh Marzouq Al Harbi and Partners Company for site preparation; and Mobarak M AlSalomi and Partners for Contracting Co – for temporary construction facilities.

Ultimately, the complex will also supply a park in the Jubail industrial area where specialty chemical plants will be located. The park will use the cracker’s production to develop specialty chemical products.

This expansion is expected to attract more than $4 billion in additional investment in a variety of industrial sectors, including carbon fibres, lubes, drilling fluids, detergents, food additives, automotive parts and tyres. It is also expected to create around 7,000 local direct and indirect jobs.

According to Amin H Nasser, Aramco President and CEO, the project marks a major step forward in further strengthening the partnership between TotalEnergies and Aramco, with the Satorp expansion project being the latest in a longstanding history of collaboration of almost five decades between both companies.

|

|

Officials at the signing ceremony held in June last year to launch the expansion. |

Meanwhile, Aramco, TotalEnergies, and Sabic have for the first time in the Middle East and North Africa successfully converted oil derived from plastic waste into ISCC+ certified circular polymers.

The plastic pyrolysis oil, also called plastic waste derived oil (PDO), was processed at the Satorp refinery. It was then used as a feedstock by Petrokemya, a Sabic affiliate, to produce certified circular polymers.

The project aims to pave the way for the creation of a domestic value chain for the advanced recycling of plastics to circular polymers in Saudi Arabia. The process allows the use of non-sorted plastics, which can be difficult to recycle mechanically, and consequently contributes to solving the challenge of end-of-life plastics.

A first milestone for the project was obtaining ISCC+ certification to assure transparency and traceability of the recycled origin of feedstock and products. Three industrial plants were involved in the process: Satrop refinery, Aramco’s Ju’aymah NGL Fractionation Plant and Petrokemya. All successfully obtained the ISCC+ certification, enabling the production of circular materials.

Aramco’s President of Downstream Mohammed Al-Qahtani said: “This achievement illustrates the importance of the petrochemical sector in creating more sustainable products and solutions. Our aim is to create circular solutions for plastic waste, while also making progress on our ambition to achieve net-zero Scope 1 and Scope 2 greenhouse gas emissions across our wholly-owned operated assets by 2050. By leveraging spare capacity of existing infrastructure, we aim to produce circular products that could be scaled up at low cost. Aramco is considering multiple ways of tapping into new technologies and leveraging existing assets to support the deployment of circular, more sustainable and lower-carbon products.”