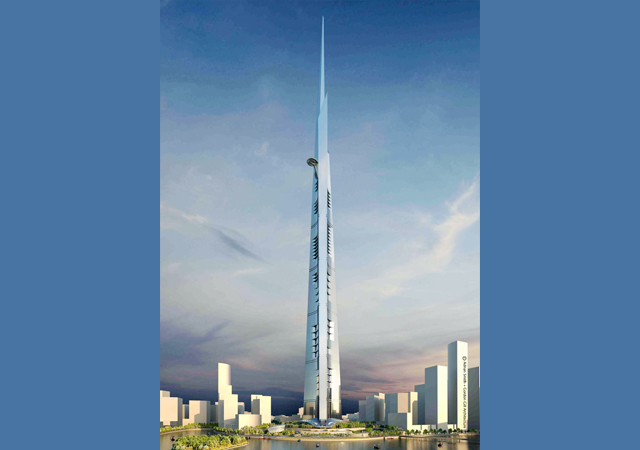

The tractor-towed Bomag RS250 has a working width of 2.5 m.

The tractor-towed Bomag RS250 has a working width of 2.5 m.

Bomag, a global market leader in compaction technology, has expanded its machine portfolio with the RS 250 and RS 300 tractor-towed stabilisers, which have a working width of 2.5 m and a milling depth of up to 40 cm and 50 cm, respectively.

Hence, the new machines can now fill a void in the fleets of construction companies and service providers looking for a flexible and economical tractor solution for milling, stabilising and mixing soils, says the Germany-based company.

The tractor-towed stabilisers are optimally designed for flexible use in soil stabilisation and road and path construction. The power-packed machines, whose design is based on numerous tried-and-tested technologies and many years of experience in the field, are driven by the rear PTO (power take-off) shaft of a powerful tractor with 200-300 hp or 300-450 hp.

“The light and manoeuvrable systems are the perfect complements, especially on smaller construction sites, but not just there. They ensure even better utilisation of tractors, which have become indispensable on modern construction sites due to their versatility and flexibility. One core application scenario is soil stabilisation: The tractor can now be used universally and flexibly to pull a binder spreader, water tank or tractor-towed stabiliser,” says Sebastian Ibald, Bomag Product Manager.

Ibald explains: “When stabilising, there is no need to replace non-load-bearing soils. Stabilising is therefore usually the better choice, both economically and ecologically, compared to removing reusable soils. By mixing in binders such as lime, this method removes moisture from the soil on site, thus improving its compaction properties and load-bearing capacity. Through the precisely dosed addition of cement and water as a hydration shell, even non-load-bearing soils can easily be made permanently load-bearing, firm and frost-resistant. With our new tractor-towed stabilisers, the highly efficient Bomag technology for milling, mixing and stabilising can now be used even more easily and flexibly on smaller construction sites. Optimised power transmission and high-performance cutting technology meet sophisticated and maintenance-friendly holder systems. They guarantee maximum milling performance, uniformly smooth surfaces after milling and comparatively low fuel consumption.”

Available in two power classes, the RS 300 (for tractors with 300-450 hp) is suitable for larger applications in stabilisation, soil improvement and road construction. The lighter and even more compact RS 250 for tractors from 200-300 hp is a good choice in road construction, for building embankments or slopes, and for backfilling.

Unlike Bomag’s familiar large, self-propelled stabilisers/planers, the new tractor-towed stabilisers rely on the tractor as the prime mover and are driven by the rear PTO shaft at an input speed of 1,000 min-1. Coupling is via the three-point hitch (category 3 or 4). On the RS 250, the milling depth of up to 40 cm can be easily and variably adjusted using the hydraulic lower link.

“The RS 300 offers even more adjustment options: The camber can always be corrected perfectly using the hydraulic upper link; independently height-adjustable side plates including skids allow free adjustment of the milling depth up to a maximum of 50 cm. Power is transmitted to the rotor via the PTO shaft, gearbox and, in the case of the RS 250, a strong chain drive in oil bath on both sides; on the RS 300, two four-part power belts are used instead,” Ibald adds.

The mixing chamber has a particularly robust design, and the hood is made entirely of wear-resistant steel with a Brinell hardness of 400. A hydraulically adjustable rear gate ensures optimal crushing and outstanding mixing quality.

On the RS 300, the large rotor with a diameter of just under 1.5 m is equipped with extra-large cutting tools with a shaft diameter of 25 mm that cut efficiently and powerfully into cohesive soils. “Thanks to the special geometry and arrangement of the double cutting tools, a shovel effect is created that ensures optimum processing and mixing of cohesive soils. Highly cohesive soils are first cut up with the shovel edge and then well mixed. This also pays off in minimal fuel consumption at low speeds. The durable RS 300 cutting tools cover a wide range of applications. The tried-and-tested quick change double-tool holder system from Bomag has a screwed base, which makes replacing and repairing quick and easy,” he says.

To hydrate the cement optimally, the RS 250 and RS 300 can be equipped with optional water injection directly into the mixing chamber. The water is distributed evenly over the entire milling width at a maximum flow rate of 500 litres per minute.

(5).jpg)

.jpg)