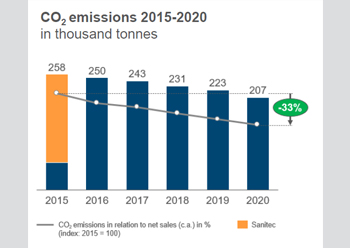

Since the integration of its energy-intensive ceramics production in 2015, Geberit has seen its relative CO2 emissions drop by 33 per cent

Since the integration of its energy-intensive ceramics production in 2015, Geberit has seen its relative CO2 emissions drop by 33 per cent

Geberit, a European market leader in the sanitary products sector, has been making impressive strides in its drive towards sustainability, by not only reducing its ecological footprint through environment-friendly operations at its facilities but also by ensuring its products contribute to enhancing a building’s green credentials.

“The absolute environmental impact of the Geberit Group decreased by 8.9 per cent in 2020, even though currency-adjusted net sales increased by 1.3 per cent in the same period. The environmental impact in relation to currency-adjusted net sales (eco-efficiency) decreased by 10.1 per cent,” Louise Pitt, Marketing and CRM Manager at Geberit International Sales, tells Gulf Construction.

She says Geberit has been measuring its ecological footprint consistently for the past 25 years, as part of a comprehensive corporate eco-balance and using this as a basis for its intended goals.

“This is unique in the sanitary industry. Since the integration of its energy-intensive ceramics production in 2015, the relative environmental impact has been reduced by 35 per cent and our goal of improving eco-efficiency by five per cent per year has been exceeded,” she claims.

|

|

Geberit has seen environmental impact reduce by 35 per cent. |

Geberit has recorded outstanding results since 2015, when it initiated an environment management programme aimed at continuous improvements in efficiency at the energy-intensive ceramics plants.

As part of its CO2 (carbon dioxide) strategy – the groundwork for which was laid back in 2007 – Geberit focuses on specific technical measures for saving energy and improving efficiency, plus the selective purchasing of renewable energy sources.

“Since the integration of the energy-intensive ceramics production in 2015, relative CO2 emissions have fallen by 33 per cent. Last year alone, CO2 emissions were reduced by 7.2 per cent to 206,563 tonnes and our target is to continue reducing emissions by five per cent annually.

Although nearly 100 per cent of Geberit’s water footprint across the entire value chain is attributable to the use of its products by customers, the company has set itself the goal of further reducing water consumption in its production processes. Water consumption has seen an 18.5 per cent drop since 2015.

Meanwhile, product development has shown results: In 2020 alone, over 3,350 million cu m of water was saved through the use of water-saving flushing systems from Geberit, Pitt states.

Products

Sustainability has been an integral part of Geberit’s corporate strategy since 1990, with the goal of developing innovative sanitary products to continuously improve people’s quality of life while taking economical, ecological and social aspects into account.

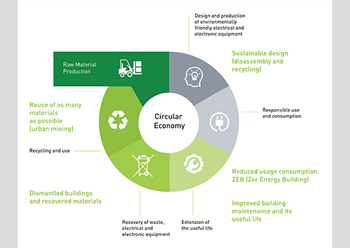

“Environment-friendly, resource-saving, durable products are extremely important at Geberit. The key here is eco-design, with all products developed consistently in line with the eco-design principle since 2007: Seen across the entire product life-cycle – from the provision of raw materials to disposal – each product must be better than its predecessor from an ecological perspective, without sacrificing on quality, functionality or durability. Eco-design covers all stages of this life cycle, thus contributing to the circular economy,” Pitt says.

Citing a recent example, she says Geberit’s product optimisation strategies have produced new flush-and-fill valves for ceramic cisterns and this revised flush technology uses more than 50 per cent recycled plastic material. This has resulted in a reduction in CO2 emissions, thanks to insourcing measures and consistent eco-design.

Pitt explains: “Where ceramic cisterns are used in toilets, a flush-and-fill valve is installed, in order for the flush technology to work correctly. As from January this year, these parts are now produced in-house by Geberit.

“In the course of insourcing measures, the flush-and-fill valve was also examined and subsequently revised which resulted in a reduction in CO2 emissions.

“As part of a complete revision of the valves, weight savings (and thus also material savings) were achieved. During this time, options were also explored for using plastic regranulates. As a result, the new fill-and-flush valves (Type 333 and Type 245) comprise more than 50 per cent recycled plastics – namely, recycled ABS (acrylonitrile-butadiene-styrene). Absolutely no sacrifices were made here in terms of the quality or functionality of the valves. Furthermore, less raw material is used overall when manufacturing the valves, which are now lighter following the revision.

“Another advantage of the optimised flush technology is a much faster and quieter filling of the cistern with water than before. Additionally, setting the flush volume is now possible in just one easy step (4/2 litres or 6/3 litres).”

The valves are backwards-compatible and can thus also be installed in older ceramic cisterns – and spare parts are available for 10 years.

Furthermore, as a result of the insourcing measures, transport distances have been reduced by up to 50 per cent. All in all, these improvements have led to a reduction in CO2 emissions of around 1,000 tonnes per year, she claims.

In addition to selecting the most suitable materials and the continuous search for environment-friendly alternatives and resource-saving design, Geberit products are also characterised by their outstanding durability.

“In many cases, their service life spans several decades. They can be maintained, cleaned and repaired easily, and Geberit offers a guaranteed spare parts availability of up to 25 years. They are also backwards-compatible, meaning older products can also be enhanced with the addition of new components and functions. These aspects play a decisive role in minimising the use of energy and resources, increasing the useful life of the products, and closing material cycles. At the same time, Geberit is constantly reducing the volume of packaging material used while simultaneously increasing the share of recycled packaging material,” she points out.

Sustainability goals

According to Pitt, Geberit operates in accordance with all three dimensions of sustainability, namely People (social dimension, having our grandchildren in mind), Planet (ecological dimension, using natural resources to the same extent that they can regenerate) and Profit (economic dimension, doing business in a way that can be continued in the long term). The three dimensions of sustainability are based on the UN 2030 Agenda for Sustainable Development and their Sustainable Development Goals.

“As a leading international company in the sanitary industry, Geberit’s solutions make a significant contribution to four of the 17 Sustainable Development Goals in particular:

Goal 6: Ensure availability and sustainable management of water and sanitation for all;

Goal 8: Promote sustainable economic growth, employment and decent work for all;

Goal 9: Build resilient infrastructure, promote sustainable industrialisation and foster innovation; and

Goal 11: Make cities and communities safe, resilient and sustainable,” she says.

Other important frames of reference for Geberit include international and national climate protection agreements and standards, as well as the UN Global Compact, of which Geberit has been a member since 2008.

.jpg)

.jpg)

.jpg)