Rosemount 2140 level detector ... safe, reliable and easy to use.

Rosemount 2140 level detector ... safe, reliable and easy to use.

Emerson’s Rosemount 2140 uses Hart protocol to provide crucial monitoring and control of liquid-filled tanks thus ensuring safety of both plant and workers.

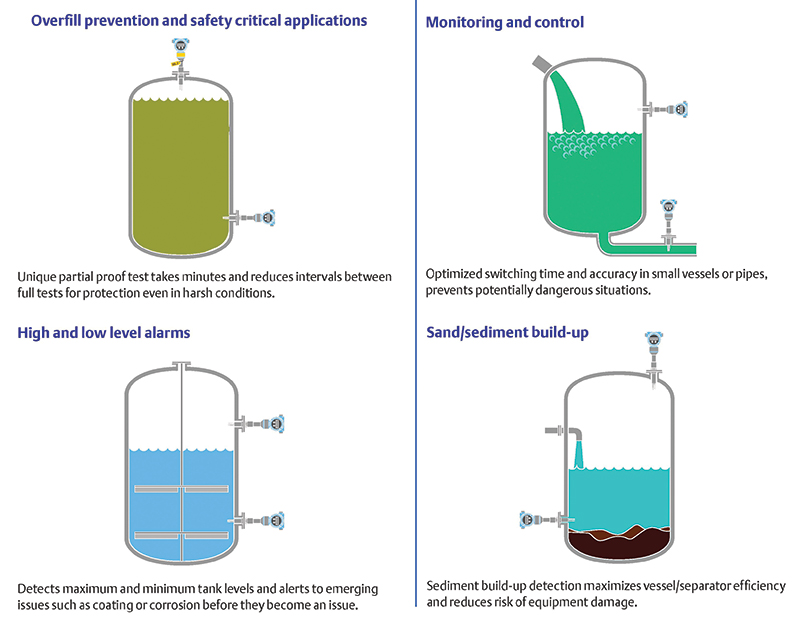

Emerson Automation Solutions has launched the Rosemount 2140, the world’s first wired Hart vibrating fork level detector for applications including overfill prevention, high and low level alarms, and pump protection.

Offering enhanced ease-of-use, smart diagnostics, and remote proof-testing capability, the device provides reliable level detection while helping increase safety and efficiency of both plant and workers.

When used to monitor and control, it optimises switching time and accuracy in small vessels or pipes, thus preventing potentially dangerous situations. In applications to identify high and low level alarms, it detects maximum and minimum tank levels and alerts to emerging issues such as coating or corrosion before they become an issue.

Listing its advantages, a company spokesman says: “The Rosemount 2140 performs in applications with high temperatures and harsh conditions unsuitable for other level monitoring devices. It is easy to install and maintain as there are no moving parts.

“The device is virtually unaffected by flow, bubbles, turbulence, foam, vibration, sediments content, coating, liquid properties and product variations. It can be used to monitor not only liquids but also liquid-to-sand interface, which enables the build-up of sand or sludge deposits in a tank to be detected.”

Compatible with the Hart 5 and Hart 7 hosts, the Rosemount 2140 enables operators to continuously monitor electronic and mechanical health. Its frequency profiling functionality immediately detects any build-up, fork blockage, or excessive corrosion, indicating maintenance may be required and allowing this to be scheduled during periods of downtime.

In addition, the power advisory functionality monitors voltage and current drawn over the device’s lifetime with a process alert for potential issues that could become a problem, such as corrosion.

An optional integral LCD display shows switch output states and diagnostics so an operator can inspect the device locally. Also, selectable media density and media learn functions help configure appropriate density settings to calculate and maintain optimum and consistent switching points in fluids of unknown properties so the device always switches with the highest degree of reliability.

For safety-critical applications, a dedicated version of the Rosemount 2140 certified to IEC61508 is available with a 97 per cent safe failure fraction and 96 per cent diagnostics coverage, making it one of the safest devices in the current SIL2 market, says the spokesman.

For installations within safety instrumented systems, a fully-integrated remote proof-testing capability eliminates the need to access the top of the vessel for extracting the device from the process. This saves time and increases process availability, worker safety and efficiency.

Emerson Automation Solutions is part of Emerson, a global technology and engineering company headquartered in the US that offers innovative solutions for customers in industrial, commercial, and residential markets. The company helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs.

|

|

Level detection applications. |

.jpg)

.jpg)

.jpg)