Haddadin ... supporting the full building envelope lifecycle.

Haddadin ... supporting the full building envelope lifecycle.

As Saudi Arabia and the wider Gulf accelerate delivery of complex mega-projects under ambitious national transformation programmes, ALUPCO’s Façade International Architectural Systems is strengthening its position as an engineering-led supplier that supports the entire building envelope lifecycle.

The company, with global ambitions, maintains a core focus on buildability, performance, and regional execution excellence.

In an exclusive interview with Gulf Construction’s Bina Goveas, Jafar Haddadin, General Manager of ALUPCO’s Façade International Architectural Systems, says the company’s competitive edge lies in how it integrates system engineering, regional manufacturing and on-the-ground technical support across the Middle East.

|

|

Projects such as the KAUST SSOIEI reflect the company’s capabilities in supporting high-performance institutional buildings. |

“This allows us to move beyond supplying aluminium profiles and instead support the full building envelope lifecycle,” Haddadin says.

This approach, he says, is increasingly relevant as Saudi Arabia and its Gulf neighbours push ahead with mega-projects under programmes such as Vision 2030, where projects are required to be delivered at greater scale and speed, alongside rising sustainability requirements.

“One of the main challenges in the region is the gap between design ambition and execution reality,” Haddadin says. “Projects often demand high performance and complex geometry, while programmes and budgets remain tight.”

He describes how the company’s dual-brand approach – leveraging both the new-generation Aluman ME platform and Vistawall International’s legacy of proven architectural glazing systems – addresses this persistent gap in the region’s building envelope sector.

ENGINEERING-DRIVEN MODEL

Haddadin outlines the company’s strategic framework centred on “buildable engineering, localisation of systems, and early technical engagement” – an approach that prioritises not just conceptual design strength but practical fabrication and installation under Middle Eastern climatic and operational conditions.

“We work to ensure that façade solutions are not only conceptually strong, but also practical to fabricate, install, and maintain in the Middle East’s climatic and operational conditions,” he says.

|

|

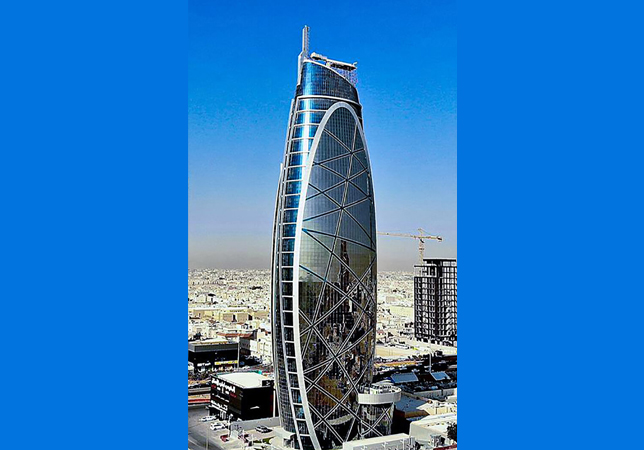

Spimaco tower in Riyadh features a Vistawall solution. |

This philosophy represents a departure from purely catalogue-based approaches common in the sector. Façade International’s strategy to address the region’s challenge in bridging the gap between design ambition and execution reality is through early technical engagement. Rather than acting as a catalogue supplier, the team positions itself as a technical partner.

For end-users – developers, consultants, and contractors – this model translates into shorter lead times, enhanced responsiveness during the design and execution phases, and improved coordination between design intent and site reality, according to Haddadin. The proximity of local extrusion facilities and regional engineering teams significantly reduces risk on complex projects and improves coordination between design intent, fabrication reality, and site execution, he emphasises.

The company’s portfolio spans façade systems, windows, doors, and sliding systems, with both brands addressing different market segments while maintaining performance standards aligned with green building certifications and regional energy codes. Rather than offering isolated products, Aluman ME and Vistawall provide system families designed for scale, performance, and adaptability across different building typologies and performance requirements.

The fundamental strength of Façade International lies in its rejection of the “import-only” model. Traditionally, high-performance systems came with the risk of long lead times and a lack of local technical accountability. Haddadin identifies local manufacturing and regional engineering as the twin pillars of the company’s competitive edge.

By extruding and fabricating locally under the ALUPCO umbrella, the brands bypass the shipping delays and customs bottlenecks that often plague GCC projects.

|

|

Boubyan Bank headquarters building Kuwait ... Facades International has carried out projects throughout the Gulf. |

CAREFUL MARKET SEGMENTATION

The strategic differentiation between Aluman ME and Vistawall International reflects careful market segmentation rather than product overlap.

Aluman ME, described as a new-generation system platform, targets projects requiring modern façade performance without excessive complexity. The brand operates under the positioning “Global System. Local Extrusions”, reflecting its foundation in European system design principles adapted for regional execution.

“Aluman ME benefits from European system design principles and engineering discipline, combined with regional manufacturing and adaptation,” Haddadin explains.

The system’s performance fundamentals including thermal behaviour, water management, and structural integrity are preserved while profile geometry, material usage, and fabrication processes are optimised for Middle Eastern requirements. Cost-effectiveness, he emphasises, is achieved without any quality compromises through engineering efficiency built into systems from inception, avoiding complexity that fails to add genuine project value.

|

|

Karbala International Airport ... facade performance proved critical. |

Vistawall International, by contrast, brings legacy credibility in complex glazing solutions, particularly for demanding curtain-wall applications. With its origins in the US and a regional office in Dubai since 2001, Vistawall is being reactivated under ALUPCO’s structure with enhanced focus on localisation and regional engineering support.

The Vistawall portfolio emphasises unitised curtain-wall systems and slim-line glazing solutions deployed on projects with complex geometry, large spans, and demanding performance requirements. Importantly, the company develops bespoke unitised solutions responding to project-specific architectural intent rather than offering only standard configurations.

“In the case of unitised systems, our approach goes beyond standard configurations. We develop customised, bespoke unitised solutions that respond to project-specific architectural intent, structural demands, and performance criteria. These systems are carefully engineered and localised for Middle East conditions, with particular focus on thermal behaviour in extreme temperatures, enhanced drainage and pressure equalisation, and robustness under high wind loads,” Haddadin says, noting that adaptation includes module dimensions, mullion depths, anchorage strategies, and movement accommodation for complex façades, tall buildings, and irregular building forms.

Similarly, Vistawall’s slim-line systems are engineered to achieve minimal visual profiles without compromising performance, balancing architectural elegance with structural integrity, thermal efficiency, and long-term durability. Material selection, finishes, and detailing are refined to suit the region’s harsh environmental conditions and local fabrication practices.

“This combination of bespoke engineering, system discipline, and regional adaptation allows us to preserve the design ambition of complex projects while ensuring that Vistawall’s flagship systems remain buildable, reliable, and performance driven,” he adds.

VISION 2030 ALIGNMENT

With Saudi Arabia’s Vision 2030 driving unprecedented construction volumes, through mega-projects including NEOM, the Red Sea Project, and Qiddiya that represent hundreds of billions of dollars in development, the façade systems market faces escalating performance and sustainability mandates.

Haddadin positions the company’s portfolio as strategically tailored to meet these requirements, highlighting system families suited for a range of building typologies rather than isolated products.

“From a Vision 2030 perspective, the focus is on high-performance façades, energy efficiency, durability, and constructability at scale,” he says.

The company’s role centres on ensuring systems remain technically robust, well-documented, and supported by engineering expertise, enabling confident deployment on large developments while maintaining commercial viability.

Both brands incorporate thermal efficiency, air-tightness, and optimised glazing integration to reduce operational energy demand. These systems are designed to support compliance with green building standards such as LEED and regional energy codes, directly contributing to lower building energy consumption – a critical consideration as Gulf states implement stricter efficiency standards.

Material selection, protective finishes, drainage strategies, and controlled movement accommodation ensure long-term durability with minimal maintenance requirements, which are particularly important given the region’s extreme temperatures and high-dust environments.

|

|

OIA Towers in Egypt ... the facade has been engineered to suit environmental conditions and local fabrication practices. |

REGIONAL ADAPTATION

A central challenge that Haddadin highlights involves adapting European-proven systems to Middle Eastern conditions, specifically climatic loads, thermal requirements, local codes, and fabrication practices, without compromising performance standards.

The adaptation process begins at the engineering level, with system configurations adjusted for drainage design, thermal breaks, structural reinforcement, and glazing options based on regional requirements.

“Importantly, adaptation also considers installer capability and workshop reality, ensuring systems can be fabricated and installed accurately without excessive risk or learning curves, while maintaining the intended performance criteria,” Haddadin notes.

This approach addresses what industry observers identify as a recurring problem in construction projects in the region: systems designed for European or North American conditions that encounter difficulties when deployed in significantly different climatic and operational contexts.

DIGITAL TOOLS AND TECHNICAL SUPPORT

Digitalisation is playing an increasingly significant role in the company’s support infrastructure, with Haddadin noting that “digital support is an important and growing part of our offering”.

BIM-ready libraries, structured engineering data, and standardised system documentation are operational, with ongoing development at Facades International aimed at enhancing design coordination and technical clarity. The progression toward AI-enabled design support and advanced engineering tools remains in the development phases.

For Vistawall specifically, differentiation from competing imported façade brands centres on direct engineering involvement. The technical team supports fabricators and contractors through structural checks, shop-drawing reviews, value engineering, and on-site coordination when required. This level of engagement ensures issues are addressed early and solutions remain aligned with system intent, he says.

|

|

KAFD Skywalk in Riyadh exemplified requirements for robust façade and glazing solutions in complex structures. |

SELECTIVE PARTNERSHIP MODEL

Façade International’s growth strategy emphasises selective, long-term partnerships with fabricators and specialists rather than broad distributor networks. This approach reflects the company’s engineering-led positioning, prioritising partners committed to quality, engineering discipline, and system integrity.

Recent and ongoing project involvement demonstrates the dual-brand portfolio’s application across demanding developments. Reference projects include Karbala International Airport in Iraq, where façade performance under complex programme constraints proved critical, and the Park Inn by Radisson Riyadh in the Saudi capital, an award-winning development that required a careful balance between architectural expression and system efficiency.

Also in Saudi Arabia, the KAFD Skywalk within King Abdullah Financial District – which now holds a Guinness World Records title for the longest continuous pedestrian skybridge network – exemplified requirements for robust façade and glazing solutions in complex structures.

Additional projects such as the Boubyan Bank headquarters in Kuwait, and institutional developments such as Suliman Saleh Olayan Innovation Entrepreneurship Institute at King Abdullah University of Science and Technology (KAUST SSOIEI) and KAUST Hotel in Jeddah, reflect the company’s capabilities in supporting high-performance institutional and commercial buildings where engineering support, system reliability, and long-term durability are critical.

MARKET OUTLOOK

Looking ahead, Haddadin identifies a fundamental market shift: higher performance transitioning from premium positioning to baseline expectation.

“The biggest trend is the move toward higher performance becoming the baseline, not a premium. We are preparing by investing in system engineering, testing, and digital support to ensure our solutions remain relevant as regulatory and performance expectations continue to rise,” he emphasises.

For medium-term competitive positioning, the company’s flagship systems include high-performance sliding systems, thermally broken windows and doors, and adaptable curtain-wall platforms configurable across multiple project types. These products respond directly to market demands for performance, efficiency, and architectural flexibility.

Haddadin’s message to architects, consultants, and developers in the Gulf is clear: Façade International delivers more than products.

“We approach façade systems from an engineering-led and partnership-driven mindset, not a catalogue approach,” he says. “Through Aluman ME and Vistawall International, we focus on delivering façade solutions that are buildable, performance-driven and carefully adapted to regional conditions, supported by genuine technical expertise.”

As the Gulf construction’s sector enters a new phase defined by greater scale, speed, and sustainability, Façade International’s combination of local manufacturing, global engineering heritage, and direct technical support positions it strategically to influence the next generation of landmark façades across the region.

.jpg)

.jpg)

.jpg)

.jpg)