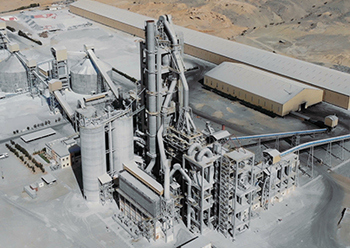

Cement producers in the Arabian Gulf region can target their carbon emissions using technology developed by VTT Technical Research Centre of Finland, says a top official at Finland’s largest research and technology company.

Eemeli Tsupari, Principal Scientist, tells Gulf Construction that VTT has developed a low-emission electricity-powered kiln that provides a solution for cement producers in the Arabian Gulf region.

“It also enables the capture of pure carbon dioxide (CO2) when lime is burned in the precalcination phase of cement production,” he says.

Tsupari elaborates: “The production of cement causes around seven per cent of all global CO2 emissions. VTT’s electric kiln is capable of making cement production close to carbon-neutral, providing the Gulf region the ability to make significant advancements in the global reduction of CO2.”

The electrically heated rotary kiln, which is expected to revolutionise the cement, quicklime and pulp production industries, has successfully completed several experiments using different feedstocks.

The production of cement – the world’s most used building material – and quicklime causes significant emissions for two reasons: Firstly, the process requires a temperature of about 1,000 deg C, and when fuel is burned to create such high temperatures emissions are released into the atmosphere. Secondly, as limestone – the main raw material of cement and quicklime – is heated, its carbonate decomposes into carbon dioxide, causing further emissions, VTT explains.

Until now, carbon-neutral production of industrial-quality burnt lime mix has been an elusive goal. However, finding a solution has become a top global priority.

“Limestone is one of the most used raw materials in the world, so we urgently need to find ways to use it in a more environmentally friendly way. At VTT, we have been able to make the crucial calcination phase more sustainable. With tests of our electric kiln, we have proven that replacing combustion processes with electricity-based solutions is an effective means of curbing climate change. Furthermore, the quality of the burnt lime product is good,” says Tsupari.

The captured CO2 can also be used for industrial purposes, from synthetic fuels to novel materials, like plastic replacements. It can also be permanently trapped, if mixed into concrete used for sidewalks, roads and bridges, Tsupari says.

The pilot kiln has been designed with transport convenience in mind. When housed inside a cargo container, it can be easily transported to industrial plants and used in different production processes, including chemical pulping in the paper industry.

“With proof of concept for the electric kiln in the precalcination phase, we are on the path towards fully decarbonising the second burn process by considering new carbon-free heat sources, such as hydrogen, to reach the necessary temperatures,” says Tsupari.

“The current high cost of natural gas makes electricity a more viable option for heating processes than gas. Solving this challenge globally could be the equivalent of taking millions of cars off the roads each year. We are now looking for partnerships with major industrial players to take this solution to the next level,” states Tsupari.

Finnsementti, a Finnish cement supplier, and Nordkalk, a leading manufacturer of limestone-based products, participated in the test process.

“The raw meal of cement production was successfully treated in the trial runs to an intermediate product which is fully calcined but not yet reacted with silica, which is exactly what we want a calciner to achieve,” says Mathias Frankenhaeuser, Technical Manager at Finnsementti.

“It’s exciting to see that properties of calcium oxide produced in the best experiment points are very near to product-grade burnt lime,” says Erkka Uuttu, Energy Manager at Nordkalk.

“Next, we would love to find a technology partner to help us build a large kiln to scale the output,” states Tsupari.

In addition to the kiln, VTT has developed solution for manufacturing carbon negative concrete, whereby carbon dioxide is forced into concrete blocks using an automated system. The process takes place at atmospheric pressure and can easily be implemented into existing manufacturing processes, says the company.

This apart, the Finnish company provides cement producers with expertise and research infrastructure for:

• Heat treatment of materials from various industries and optimisation of the operating parameters;

• Experiments with selected raw materials using the electrically heated rotary kiln and circulating fluidised bed (CFB);

• Purification and liquefaction of high-concentration CO2.