In a bid to meet the needs of Saudi Arabia’s ambitious Vision 2030 programme, ALUPCO, a leading building solutions provider, has created a new vertical – Integrated Solutions – to deliver end-to-end solutions at scale and at speed, eliminating traditional supply chains, fragmented contracting models and siloed manufacturing.

This strategic move positions ALUPCO as a critical enabler of the giga-projects being developed in the kingdom, offering a single platform of contact right from supply to delivery of various components of these complex projects.

Abdul Aziz AlGhamdi

In this exclusive interview with Gulf Construction’s Bina Goveas, ALUPCO Integrated Solutions General Manager Abdul Aziz AlGhamdi explains why the new vertical was formed, why it matters to Saudi Arabia’s giga-projects, and how ALUPCO’s landmark $500 million joint venture with China’s Asia Aluminum Group (AAG) will reshape the kingdom’s downstream aluminium industry.

ALUPCO has been extruding aluminium since 1975. For decades, it built its reputation on scale, quality and technical leadership. But as Saudi Arabia’s construction market evolved, clients increasingly wanted more than just profiles.

To address that gap, ALUPCO first created its Project Management Unit (PMU) to solve what it calls the “quadrilateral problem” – the challenges faced in coordination between developers, contractors, fabricators and suppliers. But the group quickly realised that true integration required more than coordination.

That insight led to the creation of ALUPCO Integrated Solutions, a new umbrella unit that leverages the strengths of its various units: The PMU; International Architectural Systems; ALUPCO Architectural Systems; Dynamic Engineered Solutions (tanks, MRO hangars, helipads, domes); and metal and fabrication operations.

All of these now report to one central delivery organisation that has the mandate to turn ALUPCO into one of the region’s most comprehensive construction solutions providers.

“The establishment of Integrated Solutions responds to the growing demand in Saudi Arabia and the region for holistic, end-to-end project delivery,” AlGhamdi explains. “Our market research indicated a gap where clients often navigate multiple vendors – developers, contractors, fabricators, and suppliers – which can lead to delays, misalignment, and cost inefficiencies. By uniting ALUPCO’s diverse capabilities under one umbrella, we are able to provide a single point of accountability, streamline project execution, and deliver high-quality solutions efficiently.”

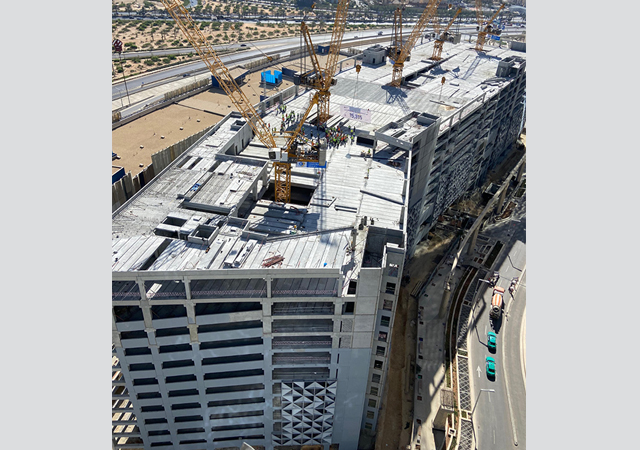

Sameem Tower, Riyadh ... innovative architectural solutions.

Integrated Solutions is designed to function as a one-stop solution provider delivering complete engineered packages.

For clients, the benefits are practical and immediate. “Clients benefit from faster decision-making, predictable timelines, reduced risk exposure, and consistent quality across all aspects of the project. Essentially, we transform complex, multi-party projects into seamless, manageable experiences,” AlGhamdi emphasises.

For contractors and developers, dealing with one integrated entity rather than a cluster of independent suppliers, simplifies negotiation, communication and claims, while leveraging ALUPCO’s scale on both the client and supply side.

This model is particularly powerful in sectors such as housing, hospitality, healthcare, education, large-scale infrastructure and mixed-use, where multiple building systems must be delivered in parallel.

AlGhamdi argues that merely supplying aluminium profiles – however efficiently – limits how much value ALUPCO can capture from the construction pipeline. “By diversifying into fabrication, fit-out, raised floors, tanks, helipads and hangars, and by integrating these offerings through a single management structure, ALUPCO can secure a larger share of each project’s spend while offering a more coherent technical proposition,” he points out.

ALUPCO Integrated Solutions’ design and engineering capabilities focus on crafting project-specific architectural, structural and specialist aluminium solutions, ensuring that concepts are practical and aligned from the outset with how they will be fabricated and installed.

The project management arm, built on the PMU legacy, oversees the entire project lifecycle, from planning and procurement through to quality control and claims, giving clients a single accountable party and reducing coordination risk.

Liwan Project Riyadh ... a major project carried out by ALUPCO Architectural Systems.

Its fabrication and production capabilities span aluminium extrusion, metal works in aluminium and steel, interior fit-out elements, tanks, roofs, aircraft hangars and helipads, allowing multiple technical packages to be delivered in a coordinated manner by one provider.

The delivery and commissioning capability covers on-site installation, integration of different systems and final handover, helping projects reach completion more quickly and transition smoothly into operation.

In addition, ALUPCO’s joint ventures and strategic partnerships, including those with Asia Aluminum Group (AAG), one of the world’s leading aluminium manufacturers, and ROSHN, Saudi Arabia’s national multi-asset developer, and technology alliances in solar, modular construction and finishes, give clients access to advanced technologies and robust, localised capacity supported by international expertise.

Projects with AAG

To support rapid scaling of production and product diversity, ALUPCO signed a $500-million master framework agreement in late 2025 with AAG to build the largest integrated downstream aluminium industrial base in the kingdom.

The project will take shape on a 1.5-million-sq-m site in Sudair, north of Riyadh, and is being developed in three major industrial streams:

• Extrusion facilities – to support the construction and solar industries, targeting initial capacity of around 100,000 tonnes in Phase One, with a long-term target of 200,000 tonnes;

• Solar frame fabrication – aiming to produce 30 million solar panel frames per year to support 25 GW of new solar projects;

• Modular housing production – in a tie-up with AAG member company AluHouse, targeting 30,000 residential modules annually through Modular Integrated Construction (MiC) systems.

According to AlGhamdi, Integrated Solutions plays a pivotal role in the joint venture by providing in-depth knowledge of Saudi Arabia’s regulatory and commercial landscape. Its expertise in local compliance, approval processes, and market conditions will enable the joint venture to enter the market efficiently. Backed by strong intelligence on major development and giga projects, Integrated Solutions aligns the venture’s strategy with national priorities. Moreover, ALUPCO’s established network and relationships will help secure future contracts, positioning the joint venture for long-term competitiveness and a sustainable project pipeline in Saudi Arabia.

Last month, Integrated Solutions signed a memorandum of understanding (MOU) with the relevant Saudi authorities to finalise arrangements for land allocation and infrastructure connections. Agreements for engineering and construction consultancy are expected to follow.

What makes the ALUPCO-AAG joint venture unique is not just its scale, but its multi-sector positioning.

Integrated Solutions is active on some high-profile developments such as Shura Island, part of the Red Sea Project.

The extrusion lines will support Saudi Arabia’s vast construction pipeline – from giga-projects to commercial and residential developments. At the same time, dedicated lines will serve the fast-growing solar industry, producing frames and mounting structures.

AlGhamdi points out that as China leads the solar supply chain, this partnership gives ALUPCO access to AAG’s technology and networks, allowing it to serve Saudi Arabia, Asia and even the US market from the kingdom.

The general manager highlights the modular housing venture as a particularly powerful vehicle for technology transfer. The Chinese partner will not only provide designs and systems but also support in building local facilities and training Saudi staff. This supports national priorities for job creation and skills development, while enabling accelerated delivery of housing and social infrastructure.

Aluminium and glass works carried out by ALUPCO on a Shura Island project.

The joint venture will also enhance the established architectural systems brands in ALUPCO’s portfolio – Aluman, Vistawall and AluK – with new high-performance profiles, curtain-wall technologies and specialised systems adapted for Saudi Arabia’s climate and mega-project requirements.

By anchoring extrusion, solar frame production and modular fabrication in Saudi Arabia, these initiatives aim to ease logistical bottlenecks that have challenged giga-projects in recent years.

Shorter lead times, lower transport risk and reduced currency exposure give developers and contractors greater certainty on both cost and schedule, AlGhamdi adds.

Al Shaikh Twin Towers in Al Khobar features ALUPCO’s systems.

ROSHN manufacturing platform

Another strategic pillar is ALUPCO’s partnership with ROSHN to establish a new facility to manufacture doors, windows and curtain-wall systems for the developer’s massive residential programme.

The plant will be fully integrated with ALUPCO’s metal and fit-out divisions, enabling the group to deliver complete building envelopes, from frames and glazing to metal works and finishing.

Sustainability is central to the design. “We will prioritise green materials, energy-efficient production and environmentally conscious engineering, in line with ROSHN’s goals and Vision 2030,” AlGhamdi says.