Work on One Za’abeel is in the final stages.

Work on One Za’abeel is in the final stages.

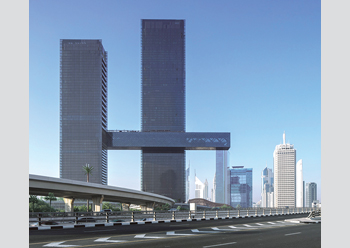

Work on the iconic mixed-use development One Za’abeel is in the final stages in preparation for its grand opening this year, according to its developer Ithra Dubai.

Following the completion of the glass cladding works on the three components – the two towers, One Za’abeel The Residences and One Za’abeel Tower, and panoramic sky concourse, The Link – fit-out works are in progress for the phased handover of the project, says the leading real estate developer and asset manager wholly owned by the Investment Corporation of Dubai.

The distinctive One Za’abeel hosts 264 opulent simplexes and duplexes as well as 26,000 sq m of premium grade-A office space available. It is claimed to feature the world’s first luxurious urban vertical resort, managed by One&Only, which includes 94 One&Only Private Homes, and 229 luxurious hotel rooms and suites. Its hospitality offering will also include a SIRO Hotel, featuring 132 rooms and a state-of-the-art wellness and recovery fitness club.

Creating the architectural and engineering marvel has demanded the highest engineering expertise and the latest technology, especially in the construction and installation of The Link, which is poised to break the Guinness World record for the “Longest Cantilevered Building”.

|

|

The Link was by far the most difficult aspect of the project. |

This sky concourse, which links the two towers of One Za’abeel that stand 304 m and 241 m tall respectively, will be an elevated lifestyle destination and several high-end attractions, including a 360-degree observation deck providing mesmerising views of the city.

The Link has been hoisted to a height of 100 m above a bustling six-lane roadway, weighing in at 8,500 tonnes, and spanning a length of 226 m.

Leading construction solutions provider Trimble says it provided a wide range of its products for the construction of One Za’abeel tower, including Tekla Structures, Tekla Model Sharing, Trimble Connect. Eversendai Engineering employed Tekla Structures, one of Trimble’s flagship products, along with collaboration tools like Tekla Model Sharing and Trimble Connect, to execute The Link.

“During the construction of One Za’abeel, The Link was by far the most difficult aspect of the project undertaken by Eversendai,” states Paul Wallett, Regional Director of Trimble Middle East and India. “Trimble’s Tekla solutions were critical during construction, as the steel module pieces were integrated in real-time. Tekla Solutions provided cutting-edge building information modelling (BIM) tools that streamlined work, increased efficiency, and facilitated coordination with other stakeholders in the construction industry.”

|

|

Paul Wallett, Regional Director of Trimble Middle East and India |

He continues: “With Tekla software, project teams could produce construction plans, analyse structural components, and build precise 3D models of structures and various stakeholders, including architects, engineers, contractors, and fabricators, were able to collaborate and communicate more effectively.”

The utilisation of Tekla Structures’ interoperability had a significant impact on the modelling process. By leveraging this capability, the process was accelerated and improved in terms of accuracy. The benefits of using Tekla Structures included the transfer or exchange of BIM data, which led to increased model accuracy and a reduction in modelling time. Moreover, early-stage clash detection was made possible by sharing data and utilising BIM modelling techniques.

“The use of tube Numerical Control (NC) files facilitated precise profile cutting of pipes, further improving the accuracy of the modelling process. Additionally, the accuracy of fabrication assembly in comparison to the fabrication drawing was verified through fabrication layout coordinates, adding another layer of quality control to the overall modelling process. Overall, the software’s powerful analysis capabilities allowed for precise evaluation of structural components and creation of detailed construction plans. Through this approach, Eversendai Engineering achieved enhanced communication, minimised errors, and maximised efficiency throughout the construction phase, leading to the successful completion of the One Za’abeel tower project,” Wallett explains.

|

|

The sky concourse pictured during its installation phase. |

Another impressive feature of One Za’abeel is its canopy which incorporates an architecturally exposed tree column with intricate curves. By utilising Tekla Structures, the canopy’s intricate design was accurately modelled and engineered, ensuring that it met all project specifications and standards.

Tekla Structures’ advanced modelling tools and visualisation capabilities made it possible to create an accurate 3D model of the canopy, including its complex curves. This was a crucial step in streamlining the fabrication process and ensuring that the final product aligned with our clients’ and stakeholders’ visions, he says.

Wallett comments: “Over the years, we have been fortunate to be involved in some of the most magnificent projects in the Middle East including One Za’abeel. The project’s complexity was heightened by the need to lift the heavy bridge to a great height and balance it between the two towers, making it a challenging feat to accomplish. It was clear that technology played a crucial role in making this project possible, given its magnitude and intricacy. Tekla Structures, one of our most renowned software, provided us with a multitude of benefits, contributing greatly to the success of the project.”

|

|

The canopy’s intricate design was accurately modelled and engineered using Tekla Structures. |

“In the same way, Tekla Model Sharing enabled teams to seamlessly share changes over the internet. All teams were able to work on local copies of a model and let Tekla’s patented synchronisation technology manage the rest of the process. This guaranteed safe, secure, and accurate data transfers and history back-ups. Trimble Connect, the cloud-based collaboration platform, also allowed teams to share, review, coordinate, and collaborate on project information in real-time, from anywhere in the world. The platform offered a wide range of features, including 3D model viewing, markups, issue tracking, and document management.”

Ramesh Babu Posa, Detailing Manager, Design & Engineering, Eversendai Engineering, UAE, says: “Working with Tekla Structures on the One Zaabeel project was an absolute game-changer. The software’s advanced modelling capabilities, improved collaboration features, and streamlined documentation processes allowed us to deliver the project with precision and efficiency. I can confidently say that Tekla Structures was a critical factor in the success of delivering the most challenging part of this project which is The Link”.

Trimble has made significant contributions to numerous major projects across the region such as Burj Khalifa, The Museum of The Future and Ain Dubai.

.jpg)

.jpg)

.jpg)