Toilets have been using the same crude mechanics for 200 years. That’s why they’re prone to breaking, clogging, partial flushes and other problems. Worst of all, they waste an obscene amount of water. To address these issues, Niagara has re-engineered the flush for a high-power, low-maintenance, no-waste toilet – making it one of the most efficient toilets on the planet. These toilets are now available from Dubai-based Mac Al Gurg, which has been appointed as the sole agent of Niagara Conservation Corporation products in the Middle East and Africa region.

This toilet with ultra-high-efficiency Stealth technology and its skirted sides conceal the trapway system guaranteeing a sleek look that is extremely easy to clean.

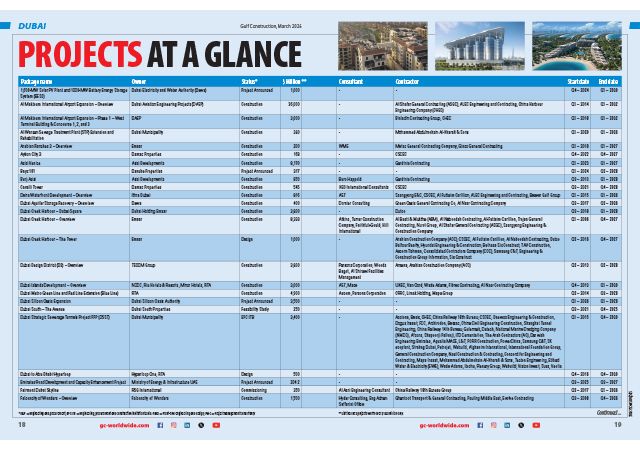

Tank

|

|

The air pressure exerted in the trapway forces water in the bowl to rise, creating a large water spot. |

The tank of Niagara’s toilet features an air transfer tube, which deploys a patented vacuum-assist flush technology that delivers a silent, powerful flush. Prior to the flush being activated, water fills the tank/inner chamber, pushing the air back into the air transfer tube. This pressurises the trapway and primes the toilet for a powerful and quiet flush.

When the flush button is pressed, water leaves the Stealth inner chamber and pulls air from the trapway up through the air transfer tube. This creates a vacuum-assisted pull that enhances the force of the water and waste flowing through the trapway. Once the flush is complete, the system refills and is primed for the next flush.

This dual flush technology has primary and secondary chambers for either a full or half-flush. When the “half” flush button is pressed, only the primary chamber is used, releasing 1.8 litres of water, to handle liquid waste. A “full” flush utilises both chambers for additional power to accommodate solid waste.

This noise-cancelling tank is equipped with a Fluidmaster 400A fill valve, the noise levels of which have been reduced dramatically. Because so little water is used, the valve is never exposed and remains submerged, cancelling out the noise produced.

With the Stealth seal, the 360-degree water flow moves into the bowl faster and easier than with a standard flapper as there is no blockage from objects. The Stealth seal is backed by a hard plastic plate which presses down and distributes pressure equally across the seal. This ensures that water does not leak while a standard flapper is prone to leak due to wafering and lack of support.

|

|

Niagara toilets feature Stealth technology. |

Bowl

Meanwhile, when the flush button is pressed, the water leaving the tank is forced through strategically placed holes around the rim of the bowl to thoroughly rinse its surface. Combined with the water that pushes through the Rim Jet – which is the larger front opening – this allows for a complete change of water in the bowl, and cleans its entire surface area.

Water that is flushed from the tank is pushed around the rim, to the nose of the bowl, in two forceful streams. As it reaches the Rim Jet, it channels water directly down into the trapway.

During the flush, pressurised air is pulled from the trapway into the Stealth inner chamber. This suction creates a powerful siphon in the trapway that pulls water and waste from the bowl and propels it down the drain line. This vacuum-assist pull is what elevates Stealth’s flush performance beyond a traditional gravity-fed toilet.

The bowl features a fully-glazed 2-inch-diameter trapway, which has been specially configured to be as streamlined as possible for the most efficient and powerful flush due to no pitch points or drastic changes in direction.

Also, being fully-glazed means reduced friction and zero absorption into the ceramic material, which helps prevent clogging and increases the flushing performance.

As the water begins to fill the inner Stealth chamber during the refill process, air is pushed through the air transfer tube. This air pressure exerted in the trapway forces water in the bowl to rise, creating a large water spot.