Abu Dhabi National Oil Company (Adnoc) has signed a AED22-billion ($6.2 billion) strategic partnership with Austrian chemical giant Borealis to build the fourth Borouge facility – Borouge 4 – at the polyolefin manufacturing complex in Ruwais, Abu Dhabi.

The signing ceremony was witnessed by Sheikh Khaled bin Mohamed bin Zayed Al Nahyan, Member of the Abu Dhabi Executive Council, Chairman of the Abu Dhabi Executive Office and Chairman of the Executive Committee of the Board of Directors of Adnoc.

The world-scale expansion confirms both partners’ commitment to the growth of Borouge and to support chemical production and advanced manufacturing and industry in Ruwais, a key pillar of Abu Dhabi and the UAE’s technology, innovation and industrial development strategy. Borouge produces crucial industrial raw materials which are exported to customers globally and used by local companies, boosting local industrial supply chains and enhancing In-Country Value.

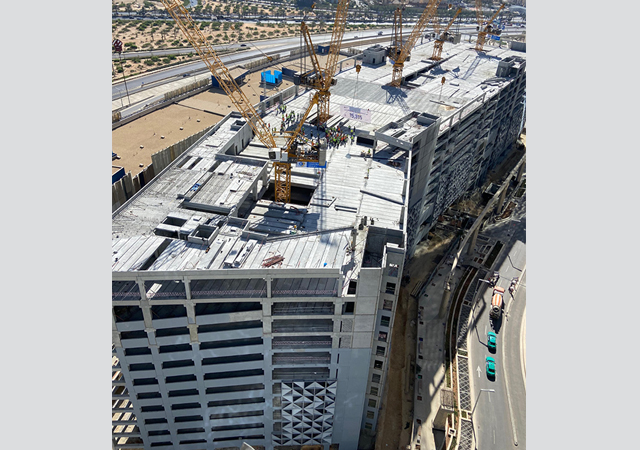

The Borouge 4 facility, which covers an area equivalent to almost 500 football pitches, or over three times the size of Al Maryah Island in Abu Dhabi, will produce enough polyolefins annually to make enough pipes to supply water to 35 million households. Borouge’s value-add materials are used to manufacture a diverse range of products including industrial-grade pipes, cables, films and personal protective equipment.

Borouge 4 will capitalise on the projected growth in customer demand for polyolefins, driven by their use in manufactured products in the Middle East, Africa and Asia. The facility will also enable the next phase of growth at the Ruwais Industrial Complex by supplying feedstock to the Ta’Ziz Industrial Chemicals Zone.

Scheduled to be operational by the end of 2025, Adnoc will supply Borouge 4 feedstock.

Borouge 4 will have an industry-leading focus on sustainability leveraging the capabilities of both shareholders. The facility will utilise Borealis’ proprietary Borstar technology, to produce a product portfolio focused on durable applications for energy, infrastructure, advanced packaging, and agriculture sectors. This unique technology, in combination with hexene co-monomer, will enable the production of advanced packaging grades with up to 50 per cent recycled polyethylene content.

.jpg)