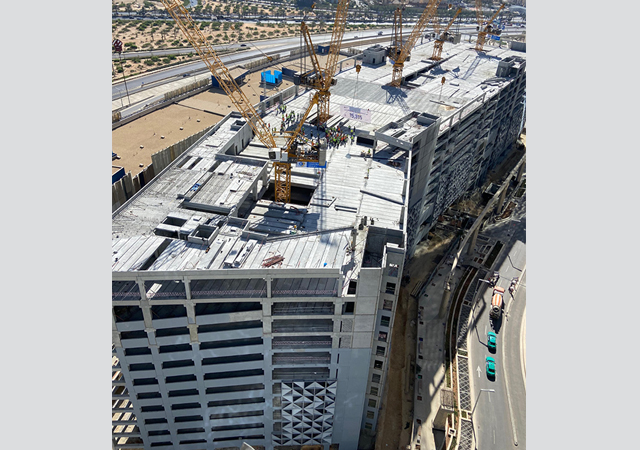

Construction of the world’s tallest tower in the Saudi city of Jeddah is proceeding apace.

The Kingdom Tower has now reached its 24th level of construction, while Schwing Stetter has just been awarded a contract to provide concrete pumping equipment for assisting in construction works.

Owned by Jeddah Economic Company (JEC), the SR4.6-billion ($1.22 billion) skyscraping tower is expected to rise to a height of more than 1,000 m with 170 storeys over an area of 85,000 sq m.

The tower will be the centrepiece of the first phase of Kingdom City, which covers 1.5 million sq m and will comprise 5.3 million sq m of multi-purpose buildings including the tower, a mall, a mosque for 12,000 worshippers, and other residential and commercial buildings.

The Kingdom Tower is designed by architect Adrian Smith and Gordon Gill Architecture, while Dar Al Handasah is the project’s construction supervisor, and EC Harris-Mace JV the project manager. The contractor is Saudi Binladin Group (SBG).

The tower will have an estimated built-up area of 465,000 sq m and is expected to be completed in Q4 2018, seizing the mantle of the world’s tallest tower from the 828-m -high Burj Al Khalifa in Dubai, UAE.

A number of works are being carried out simultaneously on and off-site. This includes preparation of the reinforcing steel for the structure, the steel coupling beams, and the cladding panels. Also, the vertical transportation motors and equipment and the mechanical and electrical plant and equipment are also being procured and readied to coincide with their installation schedule.

SBG is using and developing a numerous construction techniques to speed up work and ensure the sustainability of the structure. The concrete core and slabs are being built using a traditional jumpform system with the target floor cycle duration at four days.

“The concrete structure is extremely complex and the use of high-strength concrete up to heights of 960 m means that new methods of mix design and concrete delivery are currently being developed so that the floor cycle can be maintained,” a JEC spokesman explains.

The current plan involves numerous static pumps (including standby) at ground level which will eventually (around 500 m) be transferred to a second primary pump to deliver the concrete to the top of the structure.

The spokesman points out that there are a number of cutting-edge technologies being introduced on Kingdom Tower.

Kone, a global leader in elevators and escalators, will deliver the world’s fastest and highest double-decker elevators to the skyscraper.

The tower will be equipped with a total of 65 Kone elevators and escalators including 21 Kone MonoSpace elevators, 29 Kone MiniSpace elevators, seven Kone DoubleDeck MiniSpace elevators and eight Kone TravelMaster 110 escalators.

The Kone DoubleDeck MiniSpace elevators will utilise what is described as “revolutionary” Kone UltraRope hoisting technology.

Seven of the tower’s 170 storeys will be allocated for the five-star Four Seasons hotel offering 200 rooms, 11 storeys for 121 luxury serviced apartments, and seven storeys for offices. It will also have 61 storeys that include 318 housing units of various types, along with amenities that include gyms, spas, cafes and restaurants, two sky lobbies and the world’s highest observation decks, located at a height of 644 m, enabling visitors to view the city of Jeddah and the Red Sea from high in the sky.

A further double-height eight full refuge floors that are fire resistant will be allocated throughout the tower.

The skyscraper will feature a sky terrace – roughly 30 m in diameter – at level 157, which will be an outdoor amenity space intended for use by the penthouse floor.