Geberit’s Sovent drainage system.

Geberit’s Sovent drainage system.

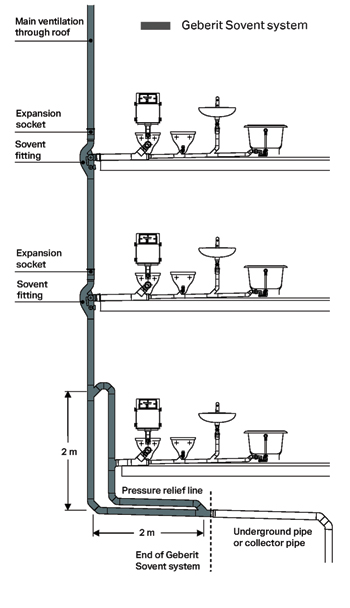

Geberit’s new hydraulically optimised fitting for the floor connection in drainage systems enables the use of discharge stacks of smaller dimensions and the possibility of dispensing with a parallel ventilation pipe, thus saving costs and space.

GEBERIT, a European market leader in sanitary technology, has introduced its Sovent flow-optimised fittings for drainage systems which enable inexpensive design of discharge stacks in high-rise buildings. They enhance the pipe capacity several times over and dispense with the need to install a parallel ventilation pipe.

“The design and engineering of drainage systems is of the utmost importance, especially in the Middle East where water is such a precious commodity. The quality of the products and materials selected for drainage systems will make all the difference when looking at government regulations on water efficiency and sanitation,” says a company spokesman.

He says the hydraulic and pneumatic balancing of a stack system is a very complex matter. Each stack design has its own characteristics. The capacity of the stack and vent system is influenced by the flow rate of the appliances, their simultaneous discharge pattern, and the branch inlet configuration and building drainage design. To secure the water seal in the traps, the positive and negative pressures in a drainage system have to be limited.

He elaborates: “Rapidly changing pressure situations in conventional discharge stacks above a certain length can lead to unwanted side effects. They could, for example, cause the floor pipes connected to the stack to be suctioned empty by high negative pressure or be blown empty by overpressure. This is why the drainage systems of many high-rise buildings include very generously dimensioned discharge stacks and a parallel ventilation pipe that is connected with the discharge stack at regular intervals.

“With the Sovent fitting, Geberit offers an inexpensive and fully technically developed alternative to the conventional design of drainage systems in high-rise buildings. Sovent prevents hydraulic closures in the discharge stack caused by floor connections, thus enhancing the flow capacity of the discharge stack.

|

|

|

“At the same time, Sovent ensures a supply of air between branch discharge pipe and discharge stack, thus making it possible to dispense with parallel ventilation pipes.”

“With Sovent in use, the installation of a parallel vent pipe becomes needless as a system that uses the Geberit Sovent fittings can manage venting easily by using one fitting on each floor level,” adds the spokesman.

He says that the opening to the stack is one of the key characteristics of the fitting, allowing the branches to be ventilated. Together with the free air circulation in the stack, the opening smoothens the water flow in the connected branches.

The terminal velocity of fall is reached after a height of 35 m with the speed at approximately 13 m per second, and cannot be higher due to friction losses and air resistance in stacks.

“The Geberit Sovent fitting itself works as a speed breaker on every floor where it is connected. In addition, a partition prevents the penetration of foam or spray water into the branch discharge pipe,” the spokesman explains.

The Sovent fitting is specifically designed for use in hotels, high-rise and multi-storey buildings, offering MEP (mechanical, electrical and plumbing) professionals two dimensions for all requirements as the fittings are characterised by the most common stack sizes of 110 and 160 mm in diameter.

The Switzerland-based Geberit Group has been a pioneer in the sector since its establishment in 1874, consistently setting new trends with its comprehensive system solutions.

Its range of products is designed for use in new buildings as well as in renovation and modernisation projects.

It comprises product lines for sanitary systems (installation systems, cisterns and mechanisms, faucets and flushing systems, waste fittings and traps, shower toilets) and piping systems (building drainage systems, supply systems).

Geberit’s products are innovative, durable and ecologically efficient and provide high-end sanitary solutions for retailers, plumbers and installers, and end-users alike.

The company has 17 production sites in eight different countries, with the main ones being located in Switzerland, Germany and Austria. It also operates sales offices in 41 countries.

Geberit currently has sales volumes of CHF2.4 billion ($2.77 billion) and employs 6,300 people in 41 countries.

.jpg)

(1).jpg)