Delivering on its vision for zero accidents, Volvo Construction Equipment (Volvo CE) has launched a Collision Mitigation System for its wheel loaders in the Middle East. This automatic braking feature supports operator response and helps reduce the risk or consequences of collision when working in reverse, says the leading manufacturer of equipment for the construction and related industries.

“It is the first safety system of its kind to be developed in-house by any original equipment manufacturer (OEM) and will help both experienced and newer wheel loader operators to improve safety on site!” a spokesperson for the company remarks.

The system assists operators while working in reverse and automatically applies service brakes when the wheel loader approaches any obstacle, alerting the operator to take further action.

With wheel loaders spending an average of 40 to 50 per cent of their time being driven in reverse, the Collision Mitigation System is a valuable solution for operators and site managers, says Volvo CE.

|

|

Nordgren ... high demand for such safety features in the region. |

Elaborating on the safety features and benefits of the system to Gulf Construction, Volvo CE’s GPE Product Manager Johannes Nordgren says: “This safety feature assists the operator before a potential accident incident by sounding an audio alert, displaying a visual alert on the Volvo Co-Pilot or rear-view camera screen, and, in the event that an object is detected within the range of the rear-view radar, automatically deploying the service brakes. The system is developed by Volvo and fulfils ISO 21815-1.”

Nordgren explains that the machine is effectively slowed down by the braking action, which lasts for two to three seconds. This forces the operator to pay attention and take action.

“The machine is still entirely the operator's responsibility. Whether the operator is coasting rearward in neutral or when the gears are engaged between 3 to 15 kph, the system is in operation.

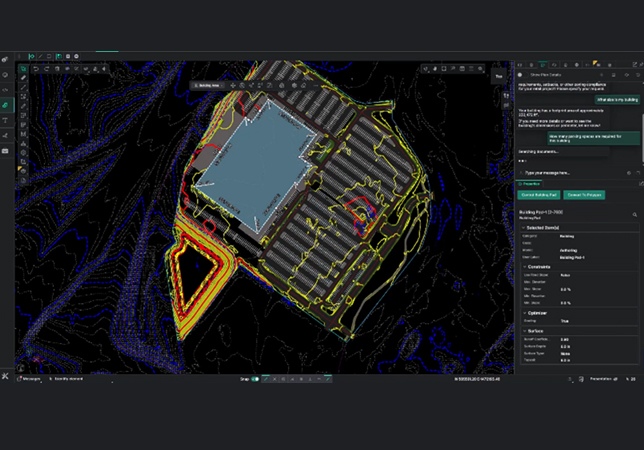

“Reverse By Braking (RBB), a new radar sensor with a broader 150-degree field of view, and the updated software are important components. The system features sophisticated software that can identify slopes or other things when driving by them forward so that it won't incorrectly regard them as items that could cause an accident when turning around in the same direction. This makes it possible for the machine to operate efficiently when doing stockpiling or other similar tasks and reversing back the same way.

“When the machine starts up, the system is always active, but it can be temporarily turned off. The system will automatically reactivate after 90 minutes if manually deactivated,” he says.

While not designed to ever replace safe operator behaviour, the system is a smart tool to further enhance jobsite safety – a central focus and core value for Volvo CE since the company’s inception.

As part of the Volvo Group, the company says it is committed to safety with its Zero Accident Vision which is delivered not only through its products, but also its operations.

|

|

The Collision Mitigation System displays a visual alert on the Volvo Co-Pilot or rear-view camera screen. |

Lars Eriksson, Global Product Manager for wheel loaders at Volvo CE, says: “We at Volvo CE continue to proactively develop intelligent solutions which not only mitigate the consequences of accidents but strive to avoid them altogether. This new Collision Mitigation System is one important part of our work to reduce the risk of accidents and help fulfil our commitment towards zero accidents.”

With this new system, customers are moving a step closer to not only eliminating accidents – and therefore improving jobsite safety for everyone – but also reducing any unplanned interruptions that can be incurred during those avoidable knocks and bumps, he adds.

Nordgren says Volvo CE sees high demand for such safety features in the Middle East and other parts of the world. Tighter safety regulations are particularly common in quarrying and mining operations, which can be particularly hazardous environments.

“The UAE and Saudi Arabia are good examples of markets where the requirements for collision mitigation systems are increasing,” he points out.

The Collision Mitigation System is available for purchase on Volvo CE’s wheel loader models L150H to L260H, which span a significant portion of its product line in the Middle East. These models are a part of the H-Series, which has all of the system-enabling features.

“The Collision Mitigation System is now only available for factory order on brand-new machines. It can be chosen by customers in consultation with their dealer, just like other machine choices. Although it is not yet available, a retrofit kit is being investigated,” he adds.

For seamless stockpiling operations, the system will remember the last slope the machine climbed, allowing operators to reverse down a pile without activating it. It can also be temporarily deactivated for specific site conditions.

|

|

The Collision Mitigation System was developed in-house by Volvo CE. |

“Even assistance systems like this cannot totally eliminate accidents though, which is why Volvo CE always advocates for safe operator driving behaviour,” Eriksson emphasises.

Developed in-house by Volvo CE, the patent-pending Collision Mitigation System for Volvo wheel loaders is a factory-fit option currently available on the L150H, L180H, L220H, L260H and L200H High Lift wheel loaders.

Requiring a radar detect system to be fitted, it works as an additional system to the existing wide range of features, options and site services provided by Volvo CE for its line of wheel loaders, all of which have been designed to elevate jobsite safety and minimise unplanned interruptions.

So why did Volvo CE choose to introduce a Collision Mitigation System for wheel loaders specifically. Nordgren explains: “Development of the Collision Mitigation System is ongoing. Since the enabling components are more readily available for wheel loaders, we have started with them. These parts are the RBB valve, and the new radar detection system. Although the radar detection system for haulers has not yet been developed, we are working with other vendors that can provide a proximity detection system in the interim.”

.jpg)

.jpg)

.jpg)