Desso brings carpets to life by incorporating technology

Desso brings carpets to life by incorporating technology

DESSO, a leading European carpet and sports pitch manufacturer, has taken the lead to demonstrate how technology can be used to improve people’s lives and at the same time bring in a new level of design freedom to architects, designers and end-users.

Its latest innovation, a light transmissive carpet that combines LED (light-emitting diode) lighting, has been created following a tie-up with Philips, a global leader in lighting.

The new LED light-emitting carpets have been developed in line with Desso’s strategy to introduce products that meet market requirements and address sustainability issues.

“The carpet industry has changed over the last five to 10 years,” says Andre Dulka, regional director, Middle East Africa and India. “Earlier, the focus was on colours and textures. The industry then used to follow the fashion industry, so whatever one saw on the catwalks was reflected in the interiors industry the following year.

“But then a few years ago, two things happened – firstly, there was an increased focus on sustainability and secondly, manufacturers realised that the future was in introducing products that were functional. They started thinking about products that would benefit the clients.”

The new LED light-emitting carpet will combine the many benefits of Desso’s carpet, such as improved indoor air quality, acoustics and comfort with the benefits of Philips’ LED lighting.

It will further unlock the potential of LED integration into surfaces and add an exciting dimension to interior design and space planning, says Dulka.

|

|

Dulka ... focus on sustainability. |

The solution will transform the way people interact with information and their environment in offices, hotels, conference centres and other public buildings, he adds.

These LED light-emitting carpets are expected to provide many benefits in the areas of information, direction, inspiration and safety, such as:

• Guiding people around buildings, including safety exits and routes;

• Enhancing the ambiance and atmosphere of the interior of buildings, combining lighting with design and colour; and

• Helping to de-clutter spaces by making information visible only when needed.

The solution is designed for high traffic areas and comes in different colours, shapes and sizes – enabling highly flexible application of the new technology.

“This light transmissive carpet solution is designed to engage directly with people’s senses and the eyes’ natural inclination to seek out light,” says Ed Huibers, marketing and sales director, Philips Lighting. “The technology takes advantage of people’s tendency to be guided by the floor when moving through and interacting with space. It brings information, direction, inspiration and safety via the carpet you walk on. This partnership of market leaders is focused on bringing meaningful innovations to the market.”

“We know people spend 90 per cent of their time indoors and our vision linked to this is to create innovative flooring solutions that contribute to people’s health and well-being. This new solution developed with our partner Philips, meets this need and offers exciting ways to enhance the interaction between the interior space and its users,” adds Alexander Collot d’Escury, CEO of Desso.

The partnership is an agreement to work exclusively together in developing the markets in Europe and the Middle East area (EMEA). In addition, a joint development agreement has been signed focusing on a seamless integration of this solution into new and existing buildings. The product name will be revealed this year as part of the full go-to-market launch, but Philips and Desso are already working on pilot projects in key markets.

Sustainable products

In line with the growing focus on sustainability, Desso initiated industry-leading policies at every stage of its manufacturing process by ensuring that its products ending their usable life were completely either biodegradable or recyclable.

The company reached a new milestone as its commercial and consumer carpet products became the first in the world to be certified under Version 3.0 of the Cradle-to-Cradle (C2C) certified product standard administered by the Cradle to Cradle Products Innovation Institute.

Desso was also the first carpet manufacturer in the EMEA to adopt the C2C design, the objective being to create continuous cycles of both biological and technical ‘nutrients’. This means that products are made from positively defined materials (ingredients that have been assessed as either green or tolerable according to C2C assessment criteria) that are easy to disassemble, in order to create new products in both the biological and technical cycles, whilst using manufacturing processes that rely on renewable energy, seek to conserve water, and to embrace social responsibility.

|

|

LED light-emitting carpets for airports. |

“We are pleased to be the first company in the world to be awarded certification under Cradle-to-Cradle certified CM Version 3.0, which will continue to help us create products that contribute to the health and well-being of local and regional residents as well as making a positive contribution towards the environment,” says Dulka.

Within this concept, Desso introduced a new carpet tile backing called Desso EcoBase. The carpet tiles have achieved Cradle to Cradle Silver certification reaching a level where up to 97 per cent of the materials are positively defined.

Prior to formal Cradle-to-Cradle certification being granted, products, materials and components must all undergo a rigorous assessment procedure. The initial stages of the certification process comprise assessing raw materials in terms of human and environmental health criteria, and evaluating the manufacturing process according to recycling potential, energy and water use, and social responsibility.

To achieve that milestone, Desso developed an innovative separation technique called Refinity, which enables the company to separate the yarn and other fibres from the backing, thereby producing two main material streams which can be recycled.

After an additional purification stage, the yarn (with the required purity) is returned to the yarn manufacturer for the production of new yarn. Some virgin material is needed to compensate for losses and process inefficiency.

The bitumen backing (used in most carpet tiles in Europe presently) is reused in road construction and the roofing sector. All non-recyclable fractions will be used as secondary fuel in the cement industry. The polyolefin-based layer of the Desso EcoBase backing is 100 per cent safely recyclable.

In addition, Desso took steps to ensure that it clients’ old carpets would be safely recycled by launching its TakeBack programme to ensure that products will be recycled according to Cradle to Cradle principles.

“We can take back all types of used carpet, except for those products containing PVC (polyvinyl chloride), to ensure it will be safely recycled into new carpet products, or used in other recycling initiatives. By sourcing positively defined raw materials, introducing new manufacturing methods and collecting used carpets from clients, we are doing everything we can to achieve a closed loop process (from production to use and back again),” Dulka says.

Desso aims to collect 50,000 tonnes of post-consumer carpet by 2020.

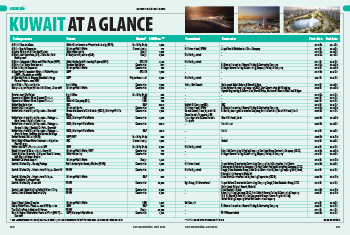

Regional base

Founded in Oss in the Netherlands, Desso entered the Dubai market 25 years ago. “There was a strong demand for contract flooring products then. Banks were opening, Jafza (Jebel Ali Free Zone) was getting busy. Most of the big manufacturers set up base here, either office or local representation, and we were amongst them,” says Dulka.

“We look after the Middle East, Africa and India and have around 60 dealers across the region to supply and install our products. They represent the brand at local level. We oversee them and promote the brand as manufacturers. We also support our dealers on projects and work with specific clients and architects on larger projects,” he concludes.

_0001.jpg)

.jpg)

.jpg)

.jpg)