Future Ceramics’ factory showroom ...<br>poised to capture market

Future Ceramics’ factory showroom ...<br>poised to capture market

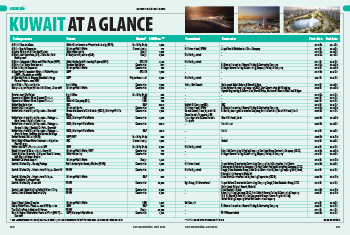

WITH production set to commence shortly at its ceramics and porcelain factory – the first of its kind in the Eastern Province of Saudi Arabia – Future Ceramics is well poised to capture a significant market share not only in the GCC region but well beyond, in Europe.

Two agreements have already been signed – one with an Italian factory for production under its name and the other with a French group to offer its products.

Future Ceramics’ marketing strategy has been drawn up as the finishing touches are being given to its factory, which is slated to start production of ceramic and porcelain in the third quarter of this year, representing the first of three phases.

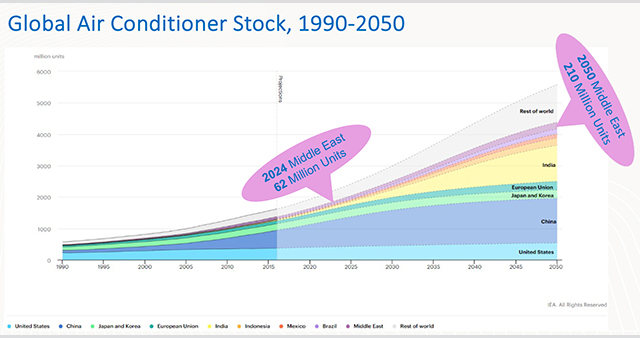

The company will focus beyond its domestic market, on the GCC and other Middle Eastern markets during the first two years in the first phase, with plans to acquire 10 to 20 per cent of the ceramic market in Saudi Arabia. The second and third phases will target acquiring shares in the European and world markets.

“With the construction sector witnessing some decline, the company is focusing on the European and American markets and is considering production on behalf of some European companies that are trying to cope with the demand for their products, especially since our products match the quality standards needed by these companies,” says Mazen Al Hammad, CEO and managing director of Future Ceramics.

Future Ceramics’ factory is considered to be the largest of its kind in the Second Industrial Area of Dammam, covering 277,500 sq m. It consists of two production lines, one for ceramic production and the other for porcelain. Total production capacity from all three phases will reach 120,000 sq m of ceramic and porcelain per day in 2012.

“The factory will employ latest Italian technology,” says Al Hammad, adding, “The management is keen to build a modern factory as per the highest technical standards with the latest furnaces and presses, as well as spray-dryers from Sacmi, the leading company in this field.”

For handling equipment, Future Ceramics has turned to Tecnoferrari whereas for inspection, sorting and packing equipment it has chosen Qualitron, Easy Line, and Falcon from System. System will also supply Rotocolor decoration technology, Al Hammad elaborates. “The delicate and important press decoration stage was assigned to technologies supplied by LB Officine Meccaniche,” he adds.

Apart from sophisticated machinery, Future Ceramics is also ensuring that it has the right team in place to enable it to attain international standards. “We have an Italian technical director, Dr Maurizio Gargioni, who is a professional with many years of experience and who has held the same position at leading Italian companies such as Pastorelli, Coop Imola and Fincuoghi. Moreover, the head of the lab in the factory is also Dario Bosani, an Italian who has worked with the Italian Iris Company. The presence of such experts will undoubtedly enhance the quality of our products in accordance with international standards,” he states.

A network of distributors and showrooms will be set up in Saudi Arabia and throughout the GCC to promote products. The first of the showrooms will be opened in Bilda Mall, Riyadh by September-end while the second showroom will be open by November in Alkharj Road, Riyadh.

Design & sizing

Al Hammad says extensive efforts have been made to ensure that designs of products are in line with the latest trends and market choice.

“Deals have been signed with some Italian designers. Gamma Due, considered one of the leading ceramics and porcelain designers, is our main designer. For glaze suppliers, we are joining hands with Colorobbia, Esmalglass and Sicer.”

“We want to ensure that we have the best in term of creativity, while catering to the tastes of our Saudi Arabian clientele. The consulting services provided by these professionals will also be essential for training of our product research department,” he says.

The company will produce tiles of various types and sizes. These include the single-fired ceramic range for floor tiles covering sizes of 43 by 43 cm, 33 by 33 cm, 50 by 50 cm and 20 by 20 cm; wall tiles of 20 by 20 cm, 20 by 43 cm and 33 by 50 cm; and porcelain tiles of 30 by 30 cm, 30 by 60 cm, 45 by 45 cm, 60 by 60 cm and 60 by 120 cm. These sizes will be produced by press while other sizes will be produced by cut.

Brand image & pricing

The company has chosen to differentiate brand names according to product type. “Orient Tiles will be used for single-fired tiles; Future Tiles for single fired and porcelain tile collections; while the Elite Tiles brand will be reserved for higher quality porcelain tile, hence the name ‘elite’.

Pricing of the products has been set keeping in view two different aspects; first, the grade of the product; and, second, the number of applications and processes involved in the production of the tiles.

“All our brands will have the same quality. However, the number of production applications is less in the Orient Tiles (ceramic red body only), so they cost less. The process is medium in the making of the Future Tiles brand (ceramic red body and porcelain) and so they have mid-range prices.

“Similarly, our top-end product which involves higher input is Elite Tiles brand (only porcelain), making its price higher,” Al Hammad concludes.

_0001.jpg)

.jpg)

.jpg)

.jpg)