The 444 G-Tier loader ... versatile and rugged.

The 444 G-Tier loader ... versatile and rugged.

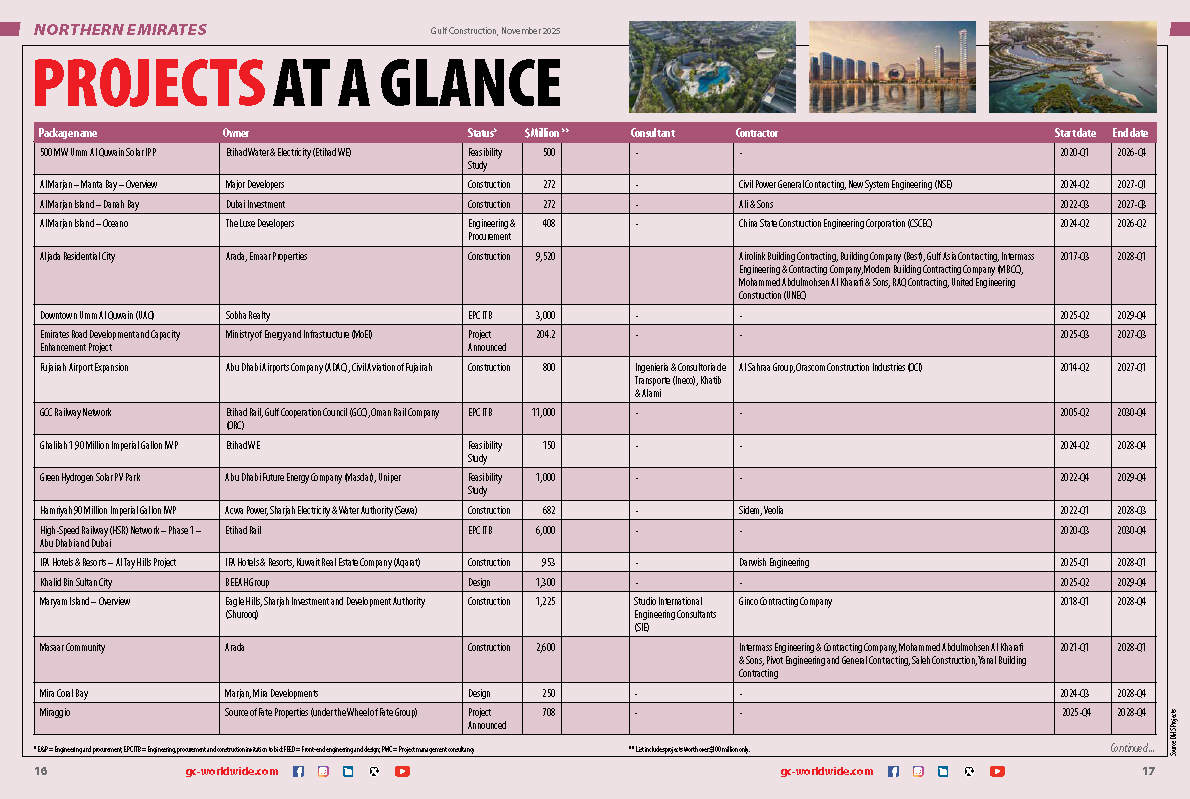

John Deere, a global leader in the delivery of agricultural, construction, and forestry equipment, has introduced the 444 G-Tier wheel loader as part of its performance tiering strategy, offering customers a model that provides reliability without the extras that they would find in a P-Tier or X-Tier machine. The new model is claimed to offer cost-effective solutions and reliable features that make for simplified maintenance and operation.

The versatility and ruggedness of the 444 G-Tier are similar to the previously introduced 544 and 644 G-Tier machines, but at a lower operating weight and smaller size, says the company.

This latest addition to the wheel loader line-up aims to cater to the segment of the construction market that values simplicity and reliability and serves as a response to the demand for more economically priced wheel loader options that don’t compromise on quality and durability, according to a John Deere official.

“Our customers are always seeking the perfect solutions to meet their needs, and the introduction of the 444 G-Tier was a direct response to the demand for reliable and more economical options within our line-up of wheel loaders,” says Drew Miller, Global Product Manager, Wheel Loaders. “This model not only comes in at an attractive price point, but it was also designed to perform and deliver the same durability and power customers expect from a John Deere machine.”

|

|

The 444 G-Tier ... economically priced. |

While offering a competitive price point, the 444 G-Tier still offers similar productivity as other models in its size class, including the 444 P-Tier wheel loader and industry leaders in its category. Among its standout features, the 444 G-Tier can be equipped with optional high-lift, expanding the reach of the machine. The optional debris package, which comes equipped with a centrifugal air precleaner and an auto reversing fan, helps reduce downtime by enabling the operator to stay up and running on the job without pausing to remove jobsite debris. This model also boasts protective transmission and bottom guards, which are specifically designed to fend off debris and ensure the machine’s longevity.

The stacked cooling package, with the hinged door for cleanout, can be set to automatically reverse at regular intervals, making for simplified maintenance. Additionally, operators will benefit from the ground-level access on the machine’s left side, making refills of major fluids, fuel and DEF (diesel exhaust fluid) straightforward and simple, Miller says.

This loader also boasts clear visibility for both transmission and hydraulic sight gauges, enhancing access to important components when needed. Its enhanced user-friendly design also includes dedicated right-side access to the machine’s engine, after-treatment systems and the cooling system.

With the operator’s ease of use and machine versatility at the forefront of its design, the 444 G-Tier is packed with familiar creature comforts, he points out. The cab, strategically crafted with ergonomic considerations, comes with adjustable controls, added floor storage space and a joystick with integrated forward, neutral, reverse controls, helping to ensure maximum comfort and ease during operation. For those seeking an added touch of comfort, optional air-ride suspension seat and ride control features help elevate the operator experience on the job.

The 444 G-Tier can be equipped with a range of attachment options, from snow blades to grapples, ensuring adaptability across different tasks and applications. Lastly, the in-cab adjustable boom settings help streamline operations, especially when performing repetitive tasks.

The new 444 G-Tier wheel loader, as well as the full line-up of John Deere construction equipment, is backed by John Deere and its network of dealers.

Also helping to keep the job running smoothly, the 444 G-Tier features JDLink in base, which enables access to service advisor remote and expert alerts, as well as support from trained technicians and access to replacement parts when needed, Miller concludes.

(5).jpg)

.jpg)