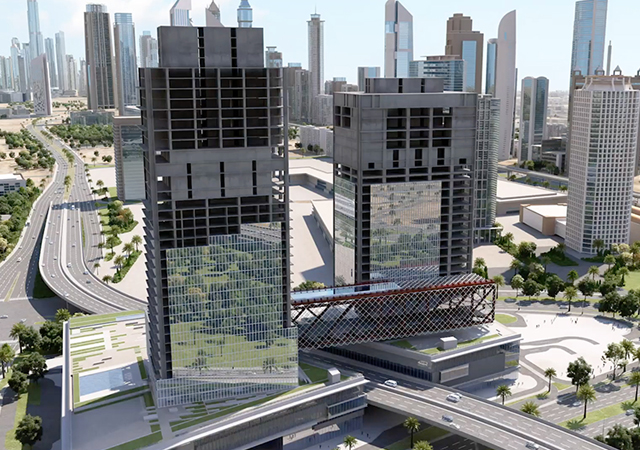

Diriyah Gate will deliver a one-of-a-kind heritage experience, including in the hospitality, retail and education spaces.

Diriyah Gate will deliver a one-of-a-kind heritage experience, including in the hospitality, retail and education spaces.

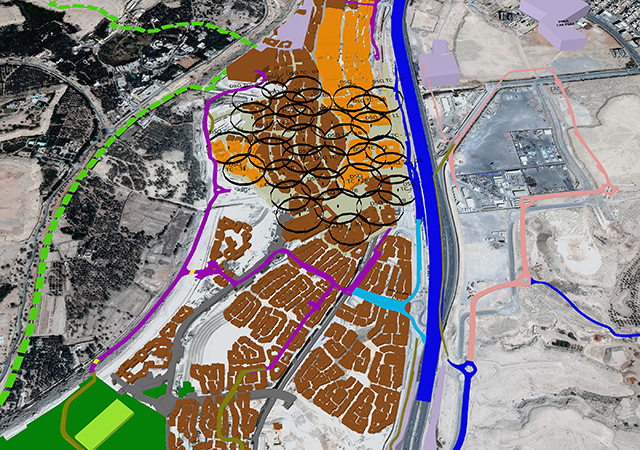

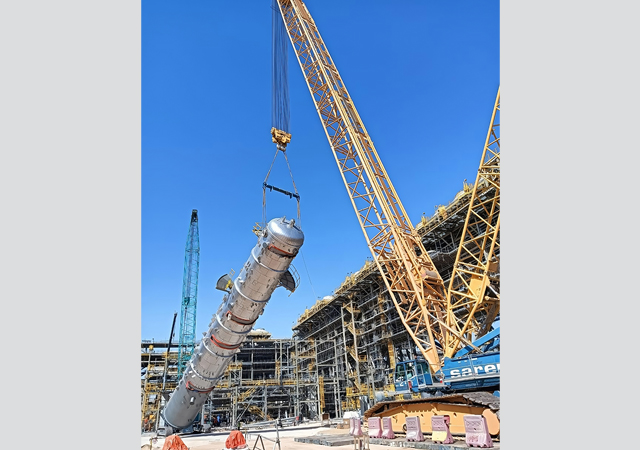

Managing logistics on the vast construction site of the $63-billion Diriyah Gate development – which covers an area of 9.3 sq km in the Saudi capital – is just one of the challenges that KEO International Consultants is tackling in delivering more than 66 assets on the giga project.

Once home to the Saudi royal family, Diriyah was declared a Unesco World Heritage Site in 2010. The mixed-use Diriyah Gate project will include extensive green spaces, parks and gardens that not only provide recreational areas, but also contribute to improving air quality. It will also include educational institutions, and research centres.

The KEO team was tasked with managing construction for all these assets on the vast project site that could expand to 14 sq km in the future.

|

|

Marion Bouillin |

For this project, KEO was responsible for providing safe, uninterrupted site access, as well as traffic and construction planning. It faced coordination and technical challenges to deliver over 66 assets in a short timeframe, all while managing public transport during construction.

Clash detection was a priority because it would ensure that the design did not have overlapping components, saving time and avoiding errors during construction. However, when searching for the right software, it quickly encountered a problem.

“Most of the available software options did not account for the timing aspect of clashes, rendering them unsuitable for our needs,” says Juan Tena Florez, Digital Services Director at KEO.

KEO needed software to not only handle clash detection, but also provide 4D construction simulations to ensure safe and timely project delivery.

Leveraging Bentley’s solution

KEO chose Bentley’s Synchro applications to meet its simulation and clash detection needs.

With this software, it was able to implement 4D digital workflows, which provided the efficiency and credibility needed to detect potential planning issues, discover better logistics opportunities, and more efficiently relay project plans to stakeholders. KEO began by using Synchro’s model-based schedule feature to create tasks from the models, then automating processes to save time during the initiation stage. Once the 4D model was complete, the team used the dynamic clash detection feature to see the project over time and export a clash detection report.

“We exported the report in many formats to be shared with the clients and stakeholders,” says Florez. “We also shared the 4D model with the project team on a monthly basis so they could benefit from navigating the model and understanding the site’s forecasting.”

|

|

By going digital, the team saved 1,992 hours on the Diriyah project. |

The team was also able to create dashboards using the Power BI connector in Synchro Control.

“Data from resources, tasks, and user fields was displayed in a beautiful dashboard,” Florez explains. Team members could even adjust and slice 3D elements using Synchro Modeler. But perhaps most importantly, Synchro helped validate logistics proposals by running them through the 4D model. “We could create videos that helped explain many complex on-site situations, as well as create time slices to show the overall project’s forecast for many years to come,” Florez adds.

KEO was able to implement a robust planning workflow encompassing a comprehensive dynamic clash detection matrix, periodic coordination meetings, and regular site surveys. These elements collectively contributed to enhancing project efficiency, minimising conflicts, and ensuring seamless coordination throughout the project lifecycle.

Synchro drives strong ROI

With Synchro, KEO can provide safe, uninterrupted access to the project site by coordinating between project teams and stakeholders. It was able to reduce the number of logistics resources by approximately 66 per cent and the time needed to identify and resolve issues by over 50 per cent. The 4D model facilitated a mobility study to optimise logistics and traffic planning, eliminating the need for a temporary bridge that would have cost $2 million, all while reducing fuel consumption and carbon emissions. Overall, it saved 272 days in potential delays along with associated costs.

By implementing digital delivery workflows, the team saved 1,992 hours and is expected to meet its project completion goal of 2027. But more than that, it has created a safe and secure site. By incorporating health and safety considerations into the 4D planning process, KEO identified and mitigated potential hazards before construction began, resulting in fewer accidents and injuries on the job site.

“Bentley’s Synchro 4D software played a pivotal role in the successful execution of the Diriyah Gate project. By integrating 4D modelling and scheduling capabilities, Synchro enabled seamless coordination and visualisation of the project’s complex construction processes. The software empowered our team to optimise project planning, enhance communication, and efficiently manage resources, resulting in improved project outcomes and timely delivery.” Florez concludes.

.jpg)

.jpg)

.jpg)