Smoke extraction systems ... engineered to effectively eliminate smoke from designated evacuation routes.

Smoke extraction systems ... engineered to effectively eliminate smoke from designated evacuation routes.

People often underestimate the potential for disaster until they find themselves in one. This is why fire safety should never be taken lightly. Yet, when it comes to fire safety solutions, many property owners compromise on quality in their relentless pursuit of cost reduction.

Unfortunately, the adoption of cost-cutting measures, such as substandard safety and compromised construction practices, has become a major cause of catastrophic building fires in the region. Instances in the UAE have surged by an unacceptable 10 per cent since 2020. Given the concerning rise in fires, the Abu Dhabi Civil Defence Authority initiated a proactive series of building inspections from May to October 2023. The outcomes revealed that over 21,000 buildings were non-compliant with national fire safety requirements, which serves as an undeniable wake-up call and indicates a direct need for optimum fire safety measures in the region.

Fortunately, the risk of fires can be reduced through dependable and high-quality smoke extraction systems. A staggering 80 per cent of fire-related casualties are caused by smoke inhalation, so reliable systems that can address the challenge of smoke are key for occupant protection.

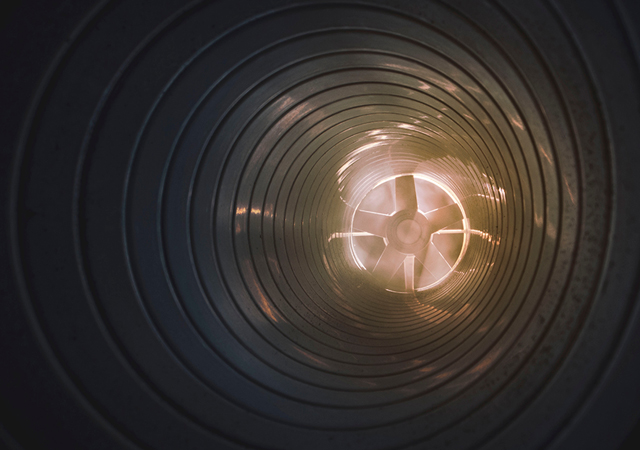

So, how exactly do smoke extraction systems operate? They consist of fans engineered to control, redirect, and effectively eliminate smoke from designated evacuation routes within a building. By supplying and channelling fresh air into the building, smoke is forced away from critical escape routes, like stairwells and corridors.

High-temperature axial fans are the most effective smoke extraction systems. Designed to quickly and efficiently extract smoke from the affected area, they improve both breathability and visibility. In the event of a fire, the regional requirement for smoke extraction fans is to perform at a minimum of 250 deg C for an hour. Nuaire’s axial high-temperature fans surpass this requirement, having been accredited by BSI and tested by a third-party organisation to confirm their ability to run at 400 deg C for up to two hours. This ultimately provides a far greater window of time for building occupants to evacuate safely.

|

|

Hughes ... opt for smoke extraction systems that are tested and certified. |

Another way in which smoke extraction systems serve as a form of fire protection is by using fans to pressurise the escape routes. The fans drive air into the building to create a positive pressure differential, which means that they keep the air pressure inside certain areas, like emergency exits or safe zones, at a higher pressure than the air in the rest of the building. The difference in air pressure prevents the entry of smoke or toxic gases into protected areas, keeping evacuation routes safe and healthy.

It’s important to opt for smoke extraction systems that are tested and certified to the highest standards, ensuring compliance with both local and international regulations. Globally recognised quality standards such as the EN12101-3 certification not only attest to reliability and effectiveness but also help buildings achieve compliance with safety measures. If properties are found to be non-compliant with quality or safety regulations, this can harm the developer’s reputation. That’s why it’s crucial to work with providers that supply test certificates with every unit, to ensure fault-free supply, direct from the assembly plant.

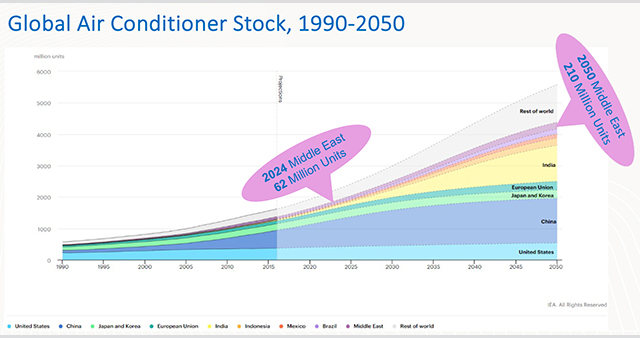

Another benefit of high-quality and certified systems is that they tend to be more sustainable. Achieving quality and safety certifications can even contribute to green building certification. As the region continues to drive sustainability forward, demand for products which are designed for energy efficiency is likely to grow.

It’s only a matter of time before green legislation comes into play and all manufacturers will begin to adapt their offering to deliver more high-performing, energy-efficient ventilation systems. Energy-efficient systems help to achieve green building certification.

Energy-efficient systems, such as the use of IE3 motors in ventilation systems, have been required by law since 2015 in the UK and EU. Not only does this reduce costs, but since the EU is a global leader in the development of regulations that govern the efficiency of such products, investing in products with an IE3 motor offers the additional benefit of long-term regulatory compliance in the Middle East. These motors even contribute to reduced maintenance costs and a longer product lifespan by minimising power consumption and extending the life of key components - all without compromising on performance.

Investing in high-quality, reliable products and enduring systems is not merely a financial consideration; it is a strategic move that holds the potential to yield many benefits for property owners. Beyond enhancing their ROI, these investments safeguard hard-earned reputations and, most importantly, prioritise the safety, well-being, and protection of those within.

* Established in 1966, Nuaire is a UK-based ventilation solutions provider designing and manufacturing products for the domestic, commercial and industrial construction sectors.

_0001.jpg)

.jpg)

.jpg)

.jpg)