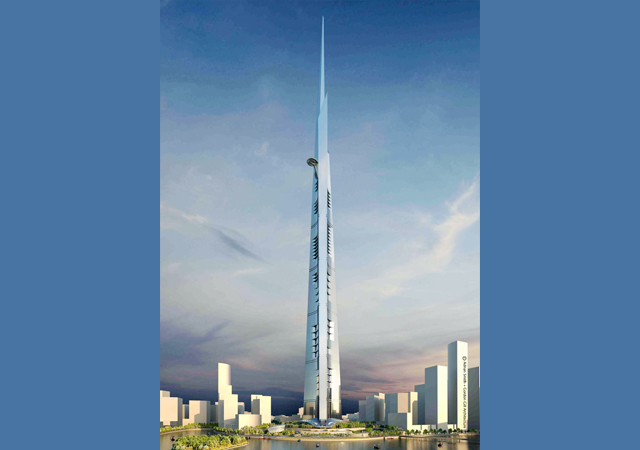

Soaring high ... an artist’s impression of the tower.

Soaring high ... an artist’s impression of the tower.

A new $200 million skyscraper being built on Sheikh Zayed Road is rising at the rate of one floor every five days with the help of formwork from Meva Schalungs-Systeme of Germany, which is being used non-stop on the project.

Rising to a height of 301 m, the Ahmed Abdul Rahim Al Attar Tower will house an office and a hotel, when complete in May 2008.

“The contractor is picking up the pace to fulfil the completion date by relying on MevaDec, a simple yet flexible system which is known to guarantee a speedy construction progress after only a short training of the jobsite personnel,” says Meva spokesman Jens Lützow-Rodenwoldt. “Only MevaDec allows building one floor after the other in four-day-intervals.”

He continues: “The formwork is being used in the construction of the world’s highest building, the Burj Dubai, and this is why contractor Al Fara’a Construction Group decided that it was the right choice, and purchased 1,500 cu m of MevaDec. Apart from easy handling, MevaDec’s low weight – the 160/80 panel only weighs 22.8 kg – plays a significant role in high-rise construction as the panels, beams and props can be moved to the next floor level without a crane.”

On a footprint of 30 by 30 m the building is rising in a weekly cycle. Two basements and the ground floor form the base for the 301-m-high tower, followed by 74 storeys with a floor height of 3.37 m. Only the ground floor and the floors 11, 42 and 73 are the exception, because these are 5 m high. A swimming pool on the 74th floor and a pyramidal spire form the very top of the building.

The staircase and lift shafts are constructed first, followed by the outer walls with integrated concrete beams all around. Only afterwards are the slabs built into the interspaces. All in all, a total of 50,000 cu m of slabs are poured with site-mixed concrete.

“MevaDec panels are equipped as standard with alkus plastic composite sheets to deliver a high-quality concrete finish,” he says. “Another positive property of the alkus-facing is the low concrete adhesion, which results in less cleaning effort – a significant advantage for tight construction schedules.”

“The contractor is convinced that it has purchased the right system, and that it will be the choice for future projects also,” Lützow-Rodenwoldt adds.

(5).jpg)

.jpg)