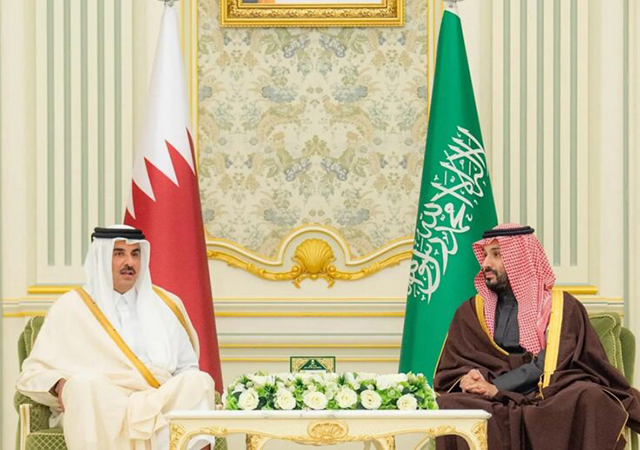

President of the Emirates Automobile and Touring Club Mohammed Ben Sulayem will patronise CAR Middle East Awards.

The CAR Awards night will be held on November 14 at the Dubai Creek Golf and Yacht Club. Awards will be presented to senior executives from the automotive industry, to celebrate key products, innovations, services, and persons in the context of the Middle East's automotive market over the last year.

The event is being held to coincide with the ninth Middle East International Motor Show to be held from November 14 to 18 in Dubai.

"Mohammed Ben Sulayem's extensive motoring experience and vast knowledge of the motor industry makes him an ideal patron for the CAR Middle East Awards," said editor of CAR magazine Shahzad Sheikh.

"I am happy to support the inaugural CAR Middle East Awards at a time when the Middle East motor trade is becoming more and more competitive. When I started to drive I couldn't have imagined the number of makes and models that we have on the roads now. These awards will serve to help people select the highest performance and most luxurious models currently available in the market," said the 14-time FIA Middle East Rally Champion Ben Sulayem.

Ben Sulayem is the driving force behind the UAE Desert Challenge and sporting ambassador for the Arab world. - TradeArabia News Service

.jpg)

.jpg)

.jpg)