Concrete 3D printing is transforming construction sites worldwide and producing high-quality homes faster and cheaper.

As the construction industry climbs out of the rut created by the Covid-19 pandemic, contractors are challenged to complete projects while protecting staff on-site, comply with government regulations and manage supply chain interruptions. Today, more than ever, the industry sorely needs new innovations to catch up on lost time and cut costs, while not sacrificing quality. This is where concrete 3D printing comes in.

The technology has the potential to significantly disrupt the construction industry, according to market research firms like Guidehouse Insights: “After years of R&D, the market is nearing a tipping point as companies are moving beyond pilots and demonstration projects. Considering current tight construction margins and labour shortages, 3D printing has the potential to revolutionise construction and unlock new markets to the industry, such as affordable homes.”

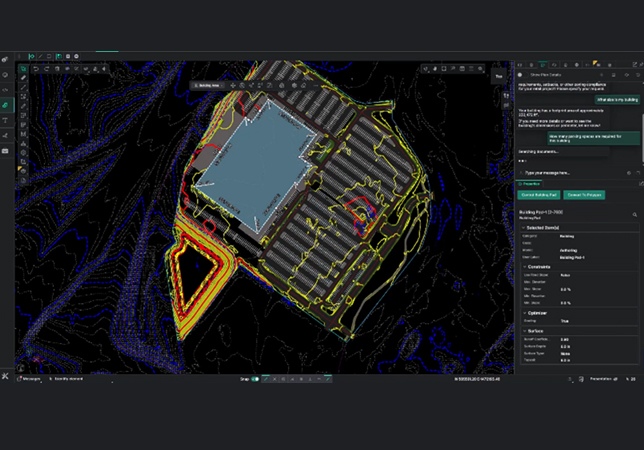

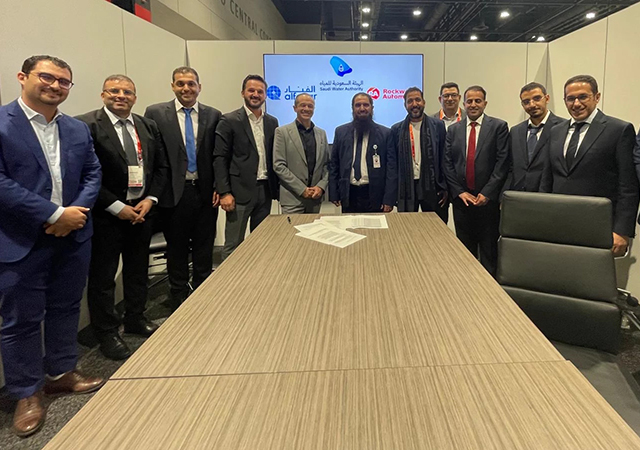

|

|

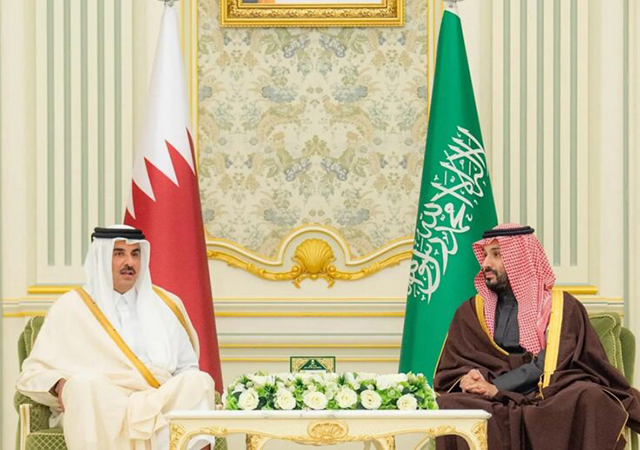

CyBe’s printed a house in Saudi Arabia for the Housing Ministry. |

Unlike the use of robotics to improve productivity, safety and quality in construction, 3D printing does not follow the conventional processes of laying bricks. “Layered construction” has become a completely new alternative technology in the construction industry. Plus, construction sites are changing. Instead of building work being carried out entirely on-site, structural modules are increasingly being pre-fabricated under industrial and automated conditions and assembled on-site, saving time and cost for better quality.

Let’s look at how companies are 3D printing homes with concrete today, what 3D printers they’re using, and what materials make it possible.

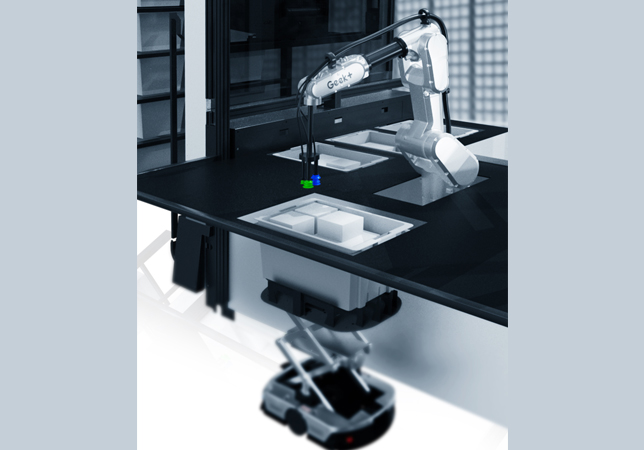

Concrete 3D printing uses extremely large-scale 3D printers, often measuring several metres in height and length to extrude concrete from a nozzle. These machines generally come either as gantry or robotic arm systems.

Whatever the printer’s configuration, practically all of them continuously extrude a dough-like concrete material that’s laid down in layers to create the desired building element. Despite being called concrete 3D printing, the used material is not always concrete in the strictest definition of the word. Traditional concrete is usually not suitable for 3D printing, as it would only clog the printer nozzle and not adhere properly to the previous layers. Many of the available materials today are unique and some are patented, making successful concrete 3D printing just as much about the material as it is about the printer.

|

|

Cobod’s printers consist of a gantry system. |

Advantages

Concrete 3D printing for construction has advanced rapidly over the past five years, with innovation in robotics, material science, and software, according to Guidehouse Insights’ research. But why is that? What does it offer in comparison to traditional building methods?

Simply put, 3D printing has the potential to upend construction in terms of speed, cost-efficiency, and productivity. That’s not empty hyperbole either – professional, high-profile companies that have tried the technology agree.

“We believe that this new technology has enormous potential for the future, and we want to help shape that future,” says Sebastian Rupp, Managing Director at German construction firm Michael Rupp Bauunternehmung, explaining why they chose 3D printed concrete. The company teamed up with Peri in late 2020 to build the first fully habitable 3D printed apartment building in Germany.

The potential of concrete 3D printing shows in printing companies’ results as well. Cobod, a Danish concrete 3D printing firm, reported its profits grew by 100 per cent in 2020, and in the first three months of 2021, it had 200 per cent more orders than in the entire previous year. The 3D printing construction market should reach a value of $1.5 billion by 2027, according to the latest estimates.

It’s easy to see why construction firms would want to move over to 3D printing. It offers significant benefits to the companies, including:

• Lower materials consumption since wall structures can be topologically optimised and partially hollow;

• Less waste, no need for large-scale concrete moulds or formwork;

• Faster building times when compared to laying bricks or concrete moulding;

• Greater degree of design freedom, able to produce geometries (curves, hollowness, etc) traditional concrete moulding can’t;

• Higher productivity (it can print 24/7); and

• Lower need for labour.

Further developments in technology will push material consumption even lower as better materials and printers will be able to create more complex and structurally sound geometries that aren’t currently possible.

However, the concrete 3D printing industry faces challenges it must overcome before widespread adoption is possible. These include high initial investment cost; limitations in print size (mostly vertically); limited selection of materials; high technical expertise required to operate and maintain printers; and the surface finish of printed elements can be visually unappealing.

Although 3D printing does cut the need for skilled labour, the workers that are needed must have a much higher degree of training and education. Additionally, tasks such as installing plumbing and electrical will continue to require human workers and they’ll need to adapt their processes to the new structures.

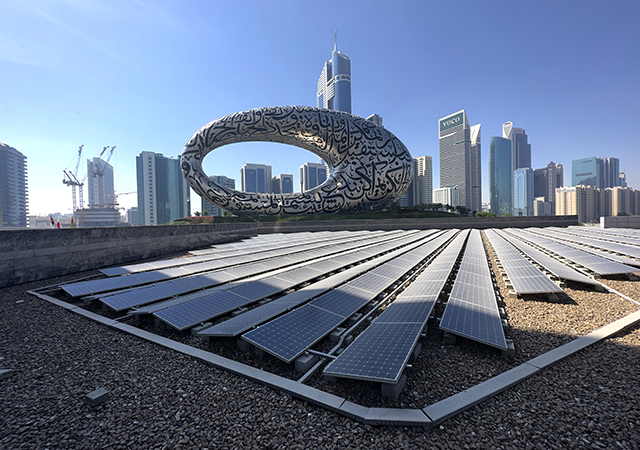

Despite the 3D printed homes and buildings making headlines today, concrete 3D printing as a market, is still in the developmental phase, but it is expected to enter the mainstream over the next 10 years, especially in countries facing labour shortages and lack of housing. Dubai, for example, is aiming to have a quarter of its buildings constructed using 3D printing by 2030. This initiative, according to the UAE’s Vice President and Prime Minister and Ruler of Dubai, Sheikh Mohammed bin Rashid Al Maktoum, enhances the role of 3D printing technologies in saving construction costs by 50 to 70 per cent, and labour costs by 50 to 80 per cent, in addition to reducing the percentage of waste resulting from construction operations by up to 60 per cent.

Concrete 3D printing might still be maturing, but that doesn’t mean the technology hasn’t been successfully put to use in a variety of projects. We’ve already mentioned a couple, like Dubai’s Office of the Future and Germany’s first 3D printed apartment building.

|

|

A Sharjah home in the SRTI Park, 3D printed in a traditional architecture style ... a project where CyBe was the technology partner. |

Other projects

• Peri’s two-storey house: Located in Beckum, Germany, the house constructed between September and November 2020, after the technology and materials had passed regulatory approval.

Peri used Cobod’s BOD2 printer and HeidelbergCement’s i.tech 3D material to print triple-skin cavity walls for the house. Only two operators printed the walls in a manner that considered the placement of water, electricity, and other connections. Thanks to BOD2’s printing process, some of the pipes and connections could be installed while the walls were still being printed.

Peri said it printed the house slower than the technology would’ve actually allowed in order to better evaluate the day-to-day operations and further cost reduction potential. Even then, the Cobod printer created 1 sq m of wall in only five minutes.

• Project Milestone’s two-bedroom home: A Dutch collaborative project between Eindhoven University of Technology, the city of Eindhoven, and other partners. After some setbacks, they completed the Netherlands’ first 3D printed house in early 2021.

The 3D printable concrete for the 94-sq-m home was developed by construction firm Saint-Gobain Weber Beamix. The house’s 24 concrete elements were printed at the university’s facilities and transported to the construction site in Eindhoven.

The collaborators intentionally chose an irregular, boulder-like shape for the home to push the limits of concrete 3D printing – and to make the house fit better in the natural environment.

• Icon’s homes for the homeless: Texas-based 3D printing firm Icon delivered a series of seven 3D printed homes for the city of Austin’s homeless in March 2020.

The first residents moved into the 400-sq-ft homes in Spring 2020, becoming the first people to live in 3D printed homes in the US. The houses were printed with Icon’s Vulcan II printer using the company’s proprietary Lavacrete material.

If you want to 3D print a house, there are 3D printing systems you can buy or 3D printing companies you can hire or partner with. Let’s take a look.

Printing as a service

Icon is currently working with a handful of strategic partners to deliver big projects both domestically and internationally as it fine-tunes its technology.

Peri is an EU-based global construction company that owns a stake in the concrete 3D printer manufacturer Cobod. The firm has partnered with engineering firms in several countries to implement 3D printing in construction.

Apis Cor is a US-based construction startup and one of the first to develop specialised equipment for 3D printing in construction capable of printing whole buildings completely on-site.

CyBe is a Dutch company that provides a comprehensive 3D concrete printing experience that includes design and engineering, 3D printing, general contracting and training.

SQ4D is a US-based construction company that prints full-size concrete houses faster, safer and stronger, while dramatically reducing costs and producing homes that are affordable, sustainable and eco-friendly, it says.

Printers for sale

Cobod sells the BOD2 printers that consist of a gantry system with several modules that are chosen to fit the specific construction project (see Page 53).

Wasp, based in Italy, sells two 3D concrete printers, the 3MT Concrete, and the Crane Wasp, which is packed with all the materials you’d need to build a house. The starter kit is designed to build residences using local material, natural recycled, or standard building material. The necessary knowledge to set up the kit is supplied online. The house project together with its contents is open source and allows project managers, designers, engineers, architects, to enter the website and take or exchange contents.

Vertico develops full concrete printing solutions, both with and without accelerated mix at the nozzle.

MudBots is another startup selling concrete 3D printers in a range of sizes.

Twente Additive Manufacturing is a Dutch printer manufacturer offering both gantry and robotic arm concrete 3D printers in a range of sizes.

CyBe offers both printers and construction. Its mobile robotic arm concrete 3D printer starts at $180,000.

Constructions-3D, a French company, offers a complete turnkey solution for concrete 3D printing on-site for half a million euros.

3D Printing with concrete

Most often, 3D printable concrete is actually a cement-based mixture of several materials, including super-plasticisers that remove water from the mix for faster drying and fibrous materials for improved strength. Providing similar functionality to concrete but with higher printability and sometimes better physical properties, the blends can be formulated for a specific purpose, such as printing walls for housing or for creating decorative architectural elements.

Most manufacturers create their own proprietary material blends, and as such, they’ve been optimised for their 3D printers (or for those of their immediate partners). Some examples of proprietary material blends include Icon’s Lavacrete and CyBe’s CyBe Mortar.

There are some basic features that set 3D printable concrete materials apart from one another. One factor is drying time. There are materials, such as those by construction 3D printer companies Mighty Buildings and Icon, that are cured using ultraviolet (UV) light. These kinds of materials cure almost instantly and can be printed horizontally without supports.

Other 3D printer manufacturers, such as Wasp, have formulated their building materials to be sourced locally, such as local earth and clay. Local material cuts down on costs, making 3D printable concrete a far cheaper option compared to traditional concrete, especially in developing nations.

Although still in the research phase, 3D printing with recycled materials, such as waste concrete from demolished buildings, is also a major eco-friendly selling point of the technology.

Printing material

Several companies have entered the 3D printable concrete market with their own products. Others make more universal materials that works with different printers, with some even formulating their material blends separately for each project. Here we take a closer look at some of the leading material producers in the field and what they have to offer.

• CyBe: The company offers its CyBe Mortar, which has been developed specifically for concrete 3D printing with CyBe printers. It is a non-metallic, low-chloride, and low-sulfate material that’s suitable for all environments, the manufacturer says. It sets in only three minutes and achieves structural strength in an hour, providing high durability and little shrinkage.

When used with CyBe printers, the material can be deposited at a maximum speed of 600 mm/s at a minimum layer height of 1 cm and a maximum of 5 cm. The company says CyBe Mortar cuts CO2 emissions by 32 per cent when compared to traditional Portland cement.

• HeidelbergCement: German building material firm HeidelbergCement’s i.tech 3D, formulated specifically for 3D printing, can be used with various types of 3D printers. Its proprietary formulation contains a mix of mineral components and additives that provide high pumpability and good extrusion properties. The material forms a strong bond with previous layers due to the fresh-on-fresh printing it enables, says HeidelbergCement.

The i.tech 3D material is particularly suitable for printing straight or curved finished parts and components, in addition to weight-bearing elements. Due to its printer agnostic nature, i.tech 3D’s print speed and other technical features will depend on the particular project and printer.

• Icon: Like i.tech 3D, Icon’s Lavacrete is a proprietary Portland cement-based blend designed to work specifically with Icon’s Vulcan II printer. Lavacrete can be made locally from easily sourced raw materials. It has a compressive strength of 6,000 psi – above that of conventional building materials – and it can withstand harsh and extreme weather conditions. The material has been formulated to have a good thermal envelope, providing insulation and comfort for the home.

The specific blend of material and additives in Lavacrete can be customised for each project and location with Icon’s Magma delivery system.

• LafargeHolcim: Swiss LafargeHolcim doesn’t produce a single named material but partners with construction companies on various projects, providing individually formulated 3D printable concrete mixes. For example, LafargeHolcim has provided a printable white cement mixture for XtreeE and is also working with Cobod and GE Energy to develop a tailor-made concrete mixture for 3D printing bases for wind turbines.

That said, in June 2020, LafargeHolcim released Tector 3D Build, its first dry mortar material range for 3D printing. Made from cementitious materials and natural hydraulic lime, the material is capable of reaching very high print speeds, the company says.

Tector 3D Build is suitable for both residential and infrastructure printing projects. Unlike some 3D printable cement materials, it can be printed vertically, allowing facades and decoration to be printed directly onto the wall.

• WinSun: China’s WinSun’s Crazy Magic Stone (CMS) is an artificial stone material that is based on a modified cement mixture. The blend is further reinforced with enhanced glass fibres.

CMS provides a smooth finish that mimics natural stone colours and textures, while providing five to 10 times higher mechanical strength than natural stone. WinSun also produces the Special Reinforced Concrete (SRC) materials, which was developed to overcome the limitations of the earlier glass-fiber-reinforced gypsum material.

* The text of “How to 3D Print a House With Concrete” by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

.jpg)

.jpg)

.jpg)